Preparation method of BiOCl hollow microsphere photocatalyst

A photocatalyst and microsphere technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problem of unclear research on BiCOl photocatalytic materials, separation of photogenerated electron-hole pairs, and hindered transfer rate. and other problems, to achieve good adsorption and photocatalytic effects, simple methods, and the effect of broadening the absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

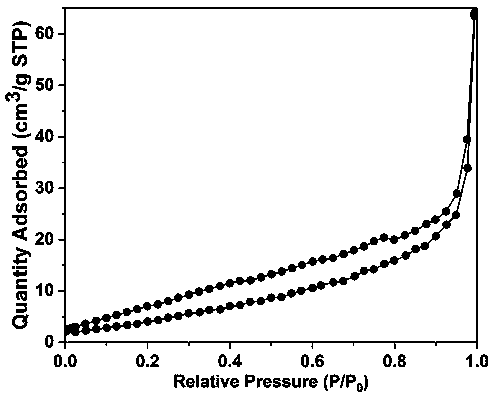

Image

Examples

Embodiment 1

[0030] Example 1 The preparation method of a BiOCl hollow microsphere photocatalyst refers to: slowly add 1L chitosan dispersion into 1.0L bismuth salt solution, stir at 5°C for 100 min to make it into a colloidal state; Slowly add 0.2L of chloride salt solution to the system under stirring conditions, and stir at a constant temperature of 5°C for 100 min; then move the reaction system into a high-pressure reactor, and homogeneously React for 24 hours, and then centrifuge to obtain the product; the product is washed with distilled water three times and dried overnight at 50°C to obtain the BiOCl hollow microsphere photocatalyst.

[0031] Among them: chitosan dispersion refers to dissolving 0.5 g chitosan in 5 mL mixed acid solution and stirring at a constant temperature of 5 °C for 100 min.

[0032] The bismuth salt solution refers to dissolving 1.5 g of bismuth salt in 5 mL of mixed acid solution and mixing evenly.

[0033] Chlorine salt solution refers to dissolving 0.2g of...

Embodiment 2

[0035] Example 2 The preparation method of a BiOCl hollow microsphere photocatalyst refers to: slowly add 1L chitosan dispersion into 5.0L bismuth salt solution, stir at 20°C for 10 min to make it into a colloidal state; Slowly add 2.0L of chloride salt solution to the system under stirring conditions, and stir at a constant temperature of 20°C for 10 min; then transfer the reaction system into a high-pressure reactor, and homogeneously React for 6 hours, and then centrifuge to obtain the product; the product is washed 9 times with distilled water and dried overnight at 200°C to obtain the BiOCl hollow microsphere photocatalyst.

[0036] Among them: chitosan dispersion refers to dissolving 5.0 g chitosan in 50 mL mixed acid solution and stirring at 20 °C for 10 min.

[0037] The bismuth salt solution refers to dissolving 15 g of bismuth salt in 50 mL of mixed acid solution and mixing evenly.

[0038] Chlorine salt solution refers to dissolving 2.0g of chloride salt in 50 mL o...

Embodiment 3

[0040] Example 3 The preparation method of a BiOCl hollow microsphere photocatalyst refers to: slowly add 1L chitosan dispersion into 3.0L bismuth salt solution, stir at 15°C for 50 min to make it into a colloidal state; Slowly add 1.0L of chloride salt solution to the system under stirring conditions, and stir at a constant temperature of 15°C for 60 min; then move the reaction system into a high-pressure reactor, and homogeneously React for 15 hours, and then centrifuge to obtain the product; the product is washed 6 times with distilled water and dried at 120°C overnight to obtain the BiOCl hollow microsphere photocatalyst.

[0041] Among them: chitosan dispersion refers to dissolving 2.5 g chitosan in 25 mL mixed acid solution, and stirring at a constant temperature of 15 °C for 50 min.

[0042] Bismuth salt solution refers to dissolving 8 g of bismuth salt in 25 mL of mixed acid solution and mixing evenly.

[0043] Chlorine salt solution refers to dissolving 1.0g of chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com