Method for manufacturing electromagnetic conductive contact of iron-nickel-based composite material by sol-gel method

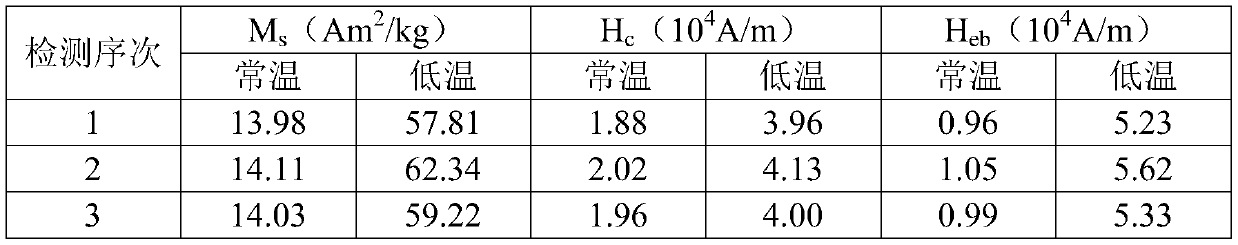

A technology of sol-gel method and composite materials, which is applied in the field of manufacturing electromagnetic conductive contacts of iron-nickel-based composite materials by sol-gel method, which can solve the problems of silver surface being easily oxidized, fatigue and fretting wear, contact area reduction, etc. problem, to achieve the effect of good performance, increased carrier concentration, and small coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of sol-gel method prepares the manufacturing method of iron-nickel matrix composite material electromagnetic conductive contact, comprises the following steps:

[0027] 1) Raw material preparation

[0028] ① Raw material preparation: prepare nickel sulfate hexahydrate 5g-5.5g, copper sulfate 3g-3.3g, zinc nitrate hexahydrate 17.5g-18g, ferric nitrate 48g-49g, polymethyl silicone resin 100g-120g, dioxide Silicon-to-polymethylvinyl silicone rubber 15g-20g, starch grafted sodium acrylate 1g-1.5g, vulcanizing agent 0.8g-1g, silane coupling agent 1g-1.5g, silver powder 5g-8g, bismuth trioxide 1g- 1.2g, enough copper clad aluminum enameled wire;

[0029] ②Auxiliary material preparation: prepare a sufficient amount of aqueous nitric acid solution with a mass concentration of 20%, sufficient amount of ethylene glycol, and sufficient amount of 3-hydroxy-1,3,5-pentanetriic acid;

[0030] 2) Glue pool preparation

[0031] ①Use the polymethyl silicone resin, silicon dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com