Coating glue solution for decorative paper and preparation method of coating glue solution

A technology for coating glue and decorative paper, applied in paper coatings, special papers, coatings, etc., can solve the problems of high base paper price, poor covering of furniture primary colors, etc., to reduce handover time, not easy to fall off, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

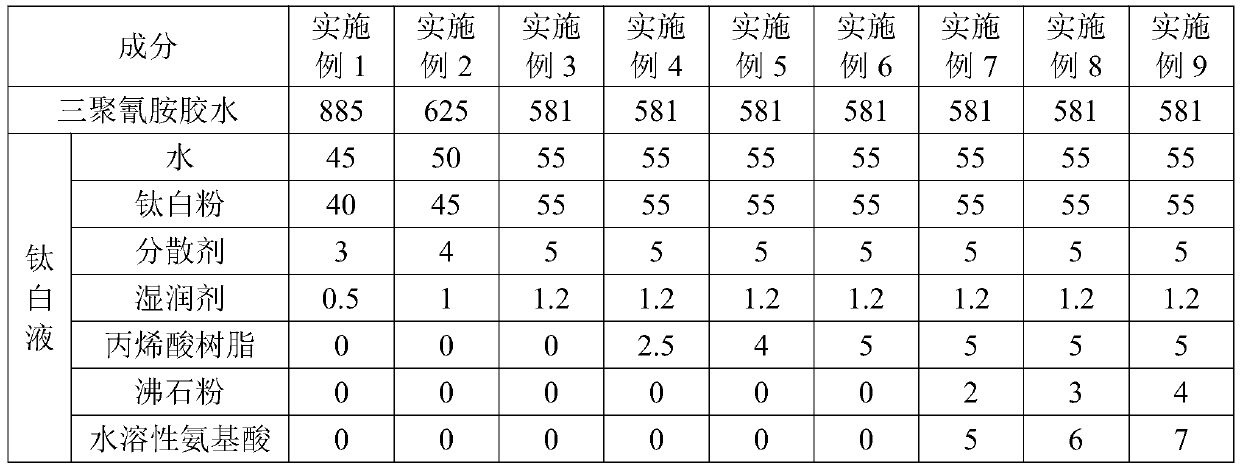

[0049] Embodiment 1-9: A coating glue solution for decorative paper, consisting of melamine glue and titanium white solution, the components included and the corresponding quality are shown in Table 1, and prepared by the following steps:

[0050] S1: Pour water and titanium dioxide into a mixing tank and stir evenly to obtain a mixed solution A;

[0051] S2: Add wetting agent and dispersant to mixture A, and grind once in a horizontal grinder to obtain mixture B;

[0052] S3: adding zeolite powder and water-soluble amino acid into the mixed solution B, stirring and mixing evenly to obtain titanium white solution;

[0053] S4: Mixing the titanium dioxide solution and the melamine glue to obtain a coating glue solution.

[0054] Table 1 embodiment 1-9 component and corresponding mass (kg)

[0055]

[0056] In the above examples, Chemours Titanium Dioxide R-796+ was used as the titanium dioxide, 80-100 mesh as the zeolite powder, and PE-100 was used as the wetting agent.

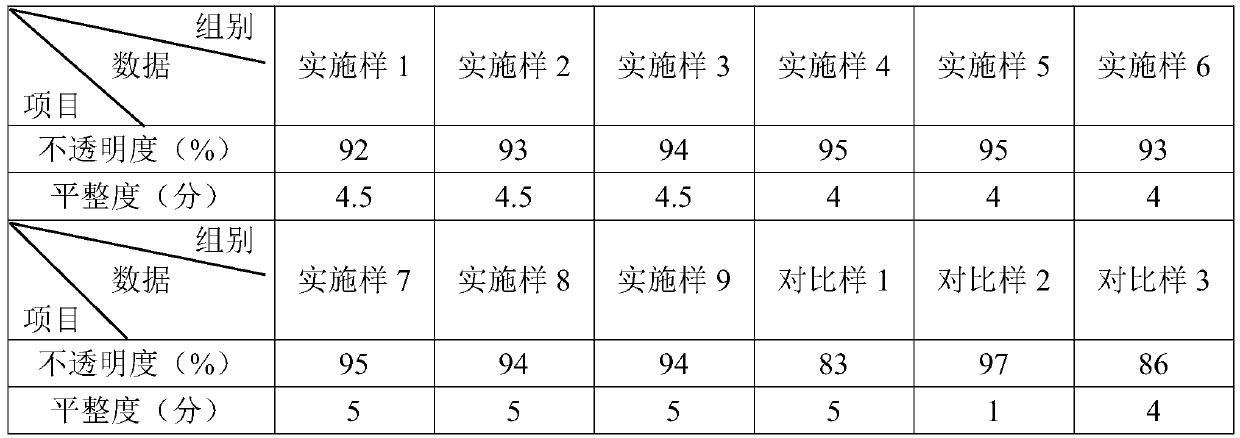

...

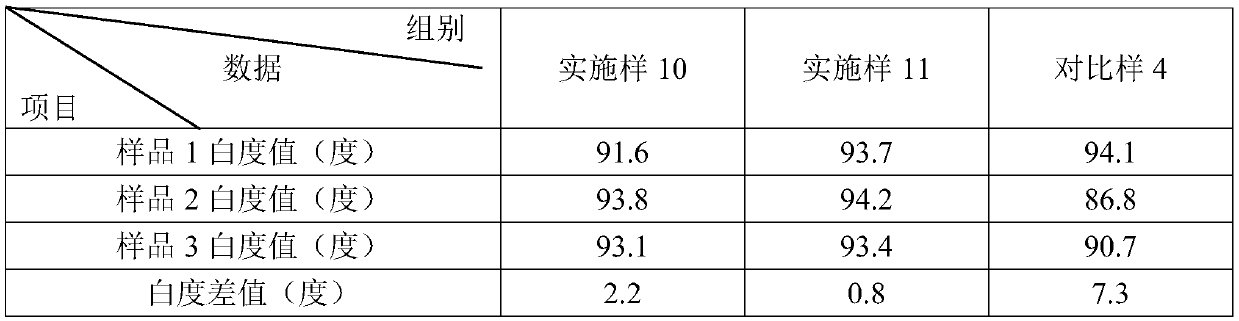

Embodiment 10

[0066] Embodiment 10: a kind of preparation method of coating glue, comprises the following steps:

[0067] S1: Pour water and titanium dioxide into a mixing tank and stir evenly to obtain a mixed solution A;

[0068] S2: Grind the mixed solution A twice in a horizontal grinder, then add the wetting agent and dispersant to the mixture A, and grind it once in the horizontal grinder to obtain the mixture B;

[0069] S3: adding zeolite powder and water-soluble amino acid into the mixed solution B, stirring and mixing evenly to obtain titanium white solution;

[0070] S4: Mixing the titanium dioxide solution and the melamine glue to obtain a coating glue solution.

Embodiment 11

[0071] Example 11: A preparation method of coating glue, the difference from Example 10 is that in S2, before adding the wetting agent and dispersant to the mixture A, the mixture A is ground three times in a horizontal grinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com