Ultrasonic vibration device for coaxial ultrasonic-assisted laser shot peening

An ultrasonic-assisted, laser shot peening technology, applied in the direction of fluid using vibration, can solve problems such as unfavorable fatigue strength, unfavorable material structure, difficult control, etc., and achieve the effect of promoting dynamic recrystallization behavior, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

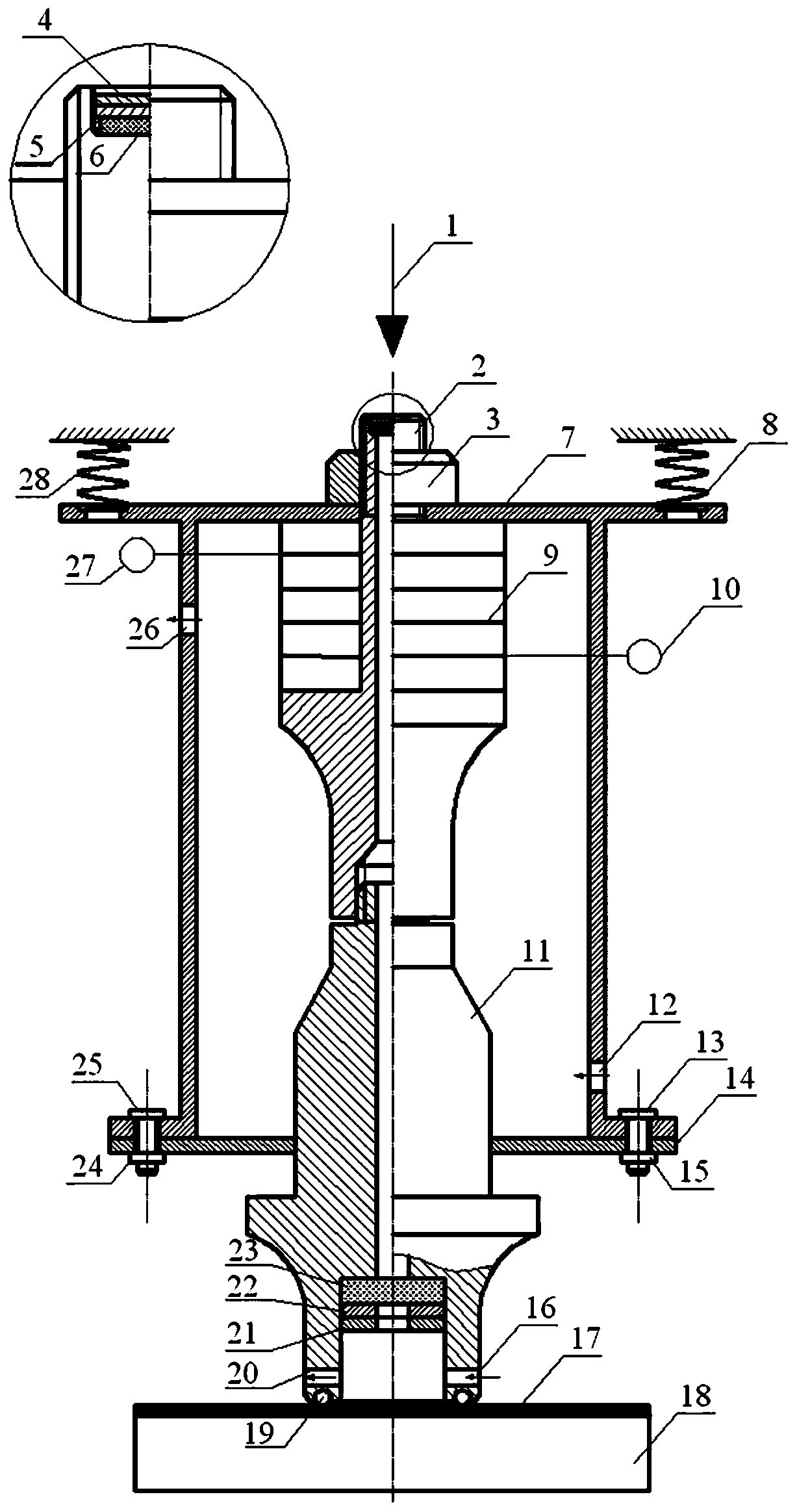

[0024] like figure 1 As shown, the ultrasonic vibration device for coaxial ultrasonic-assisted laser shot peening according to the present invention mainly includes a vibrating rod 2, a horn 11, piezoelectric ceramics 9, a first optical glass 6, and a second optical glass 23 , wherein the light transmittance of the first optical glass 6 and the second optical glass 23 is higher than 99.9%.

[0025] The axial center of the vibrating rod 2 and the horn 11 is processed with a through hole, the lower end of the vibrating rod 2 is fixedly connected with the upper end of the horn 11; the first optical glass 6 is located on the top of the vibrating rod 2, and the second optical glass 23 is located on the horn 11 bottom. Specifically, concave holes are provided on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com