A startup system and method based on supercritical water oxidation technology

A supercritical water oxidation technology, which is applied in chemical instruments and methods, sludge oxidation treatment, oxidized water/sewage treatment, etc., can solve problems such as salt deposition, blockage, and coking of electric heaters, and reduce operating costs. The effect of saving power loss and reducing start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

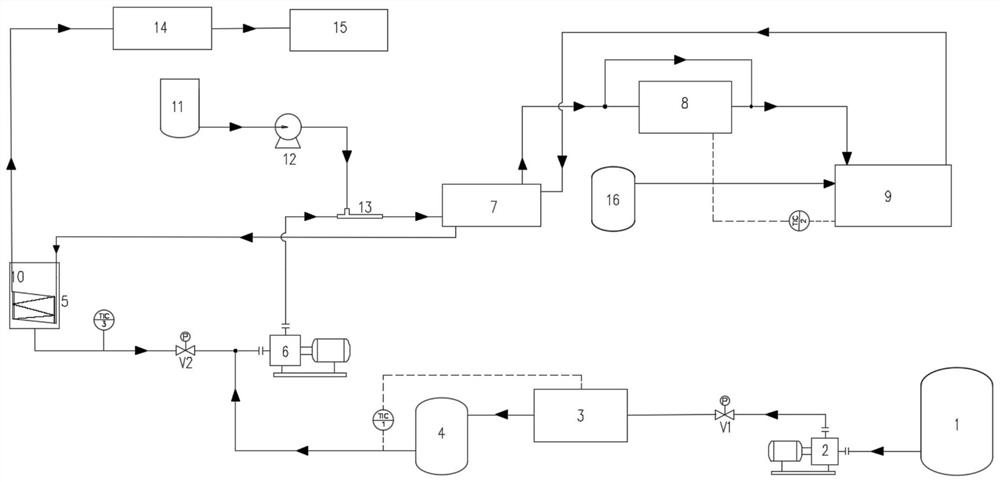

[0053] see figure 1 , this embodiment takes supercritical water oxidation technology to treat industrial sludge as an example, and describes the start-up scheme of supercritical water oxidation system in detail:

[0054] The start-up system based on the supercritical water oxidation technology of the present invention includes a material pretreatment unit, an oxygen supply unit, a water supply unit, a fuel supply unit, a supercritical water oxidation reaction and a postprocessing unit. The connection method of each device is as follows:

[0055] The outlet of the material mixing tank 5 is connected to the inlet of the high-pressure material pump 6, the outlet of the high-pressure material pump 6 is connected to the inlet of the inner pipe of the preheater 7, and the outlet of the inner pipe of the preheater 7 is connected to the inlet of the second electric heater 8 , the outlet of the second electric heater 8 is connected with the inlet of the supercritical water oxidation r...

Embodiment 2

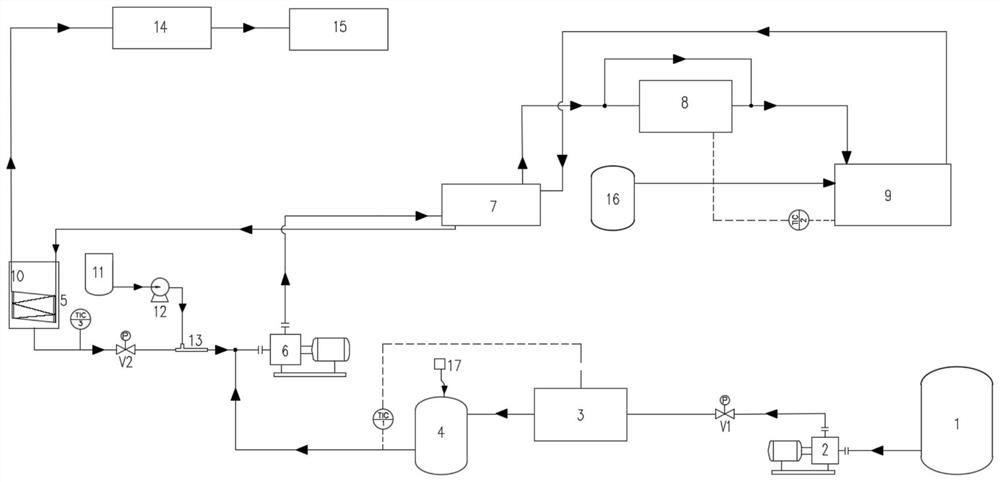

[0074] Such as figure 2As shown, the start-up system based on the supercritical water oxidation technology in this embodiment includes a material pretreatment unit, an oxygen supply unit, a water supply unit, a fuel supply unit, a supercritical water oxidation reaction and a post-treatment unit.

[0075] The difference with Example 1 is:

[0076] The fuel supply unit includes a fuel storage tank 11 , a fuel metering pump 12 and a mixer 13 . The outlet of fuel storage tank 11 is connected with the inlet of fuel metering pump 12 , the outlet of fuel metering pump 12 is connected with the inlet of mixer 13 , and the outlet of mixer 13 is connected with the inlet of high-pressure material pump 6 .

[0077] The water supply unit includes a water storage tank 1 , a starting feed water pump 2 , a first electric heater 3 , a water distribution tank 4 , and a constant pressure device 17 . The outlet of the water storage tank 1 is connected to the inlet of the starting feed water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com