A combined pressing method for continuous casting slabs

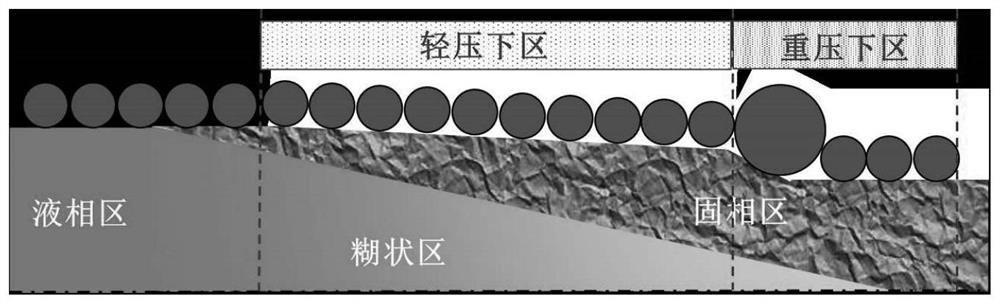

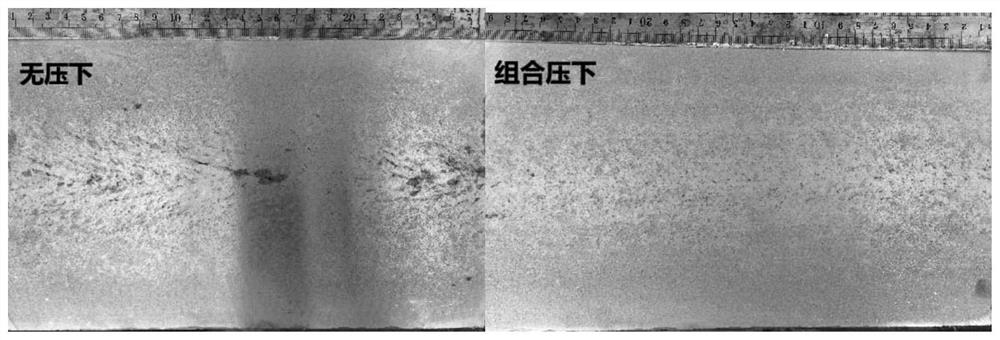

A continuous casting slab and casting slab technology, which is applied in the field of continuous casting slab combination reduction, can solve problems such as unstabilized process effects, achieve the effects of improving macro segregation and center loose defects, improving internal quality, and significant reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

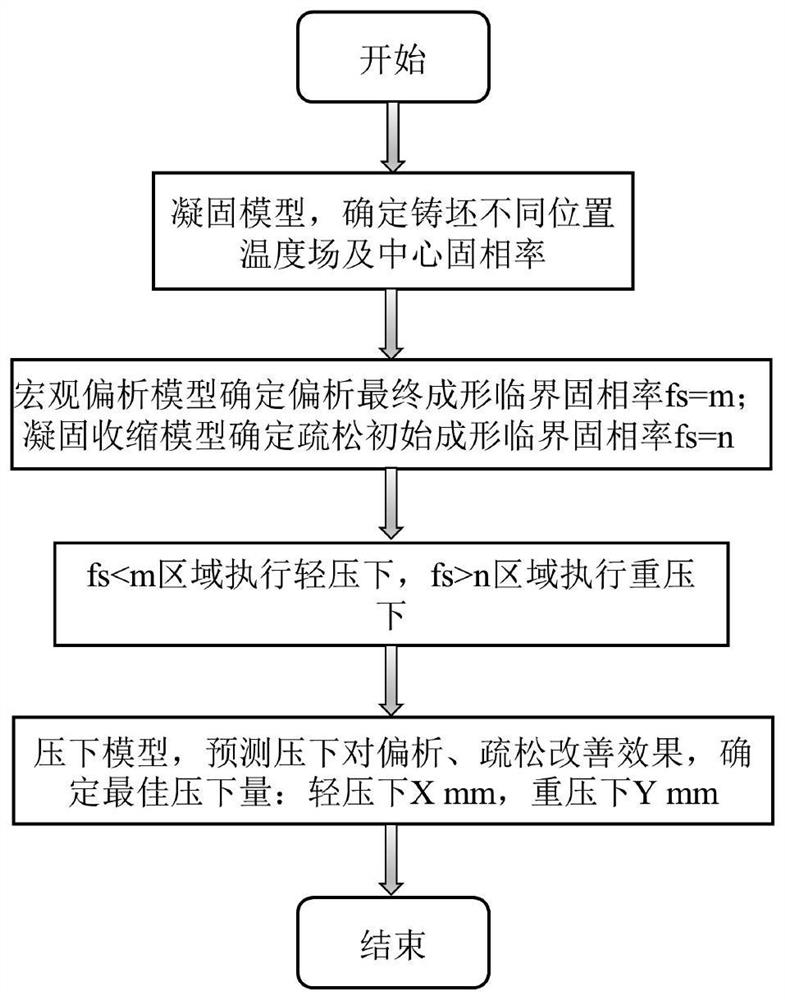

Method used

Image

Examples

Embodiment 1

[0083] Specification of continuous casting billet: 165*165mm square billet; the implemented steel type is 82B high carbon steel; implemented casting speed: 1.65m / min;

[0084] Through the macro-segregation model and porosity model prediction results established, the final formation position of central segregation and the reasonable position of porosity formation can be obtained. Figure 4 The evolution law of the central segregation calculated by the model is given. It can be seen that when the end of solidification is approaching, the central segregation basically does not change, that is, the central segregation will eventually form when it is close to the end of solidification. In this example, the solid phase ratio is 0.71 place. Figure 5 Shown is the evolution of the theoretical value of porosity in the solidification process calculated by the porosity model. The results show that when the solid ratio of 3 critical feeding is 0.7, the porosity diameter is 2 mm, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com