Column-distributed ventilation heating system and method for high-pollution oil mist emission plant

A heating system, distributed technology, applied in the distributed ventilation and heating scheme along the column, and the distributed ventilation and heating system along the column, it can solve the problem of difficult to meet the thermal comfort requirements of tall factory buildings, difficult to control the internal area of large space factory buildings, and the number of air supply outlets Issues such as the area can bear the load limit, to achieve the effect of improving the quality of the working environment, improving ventilation efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

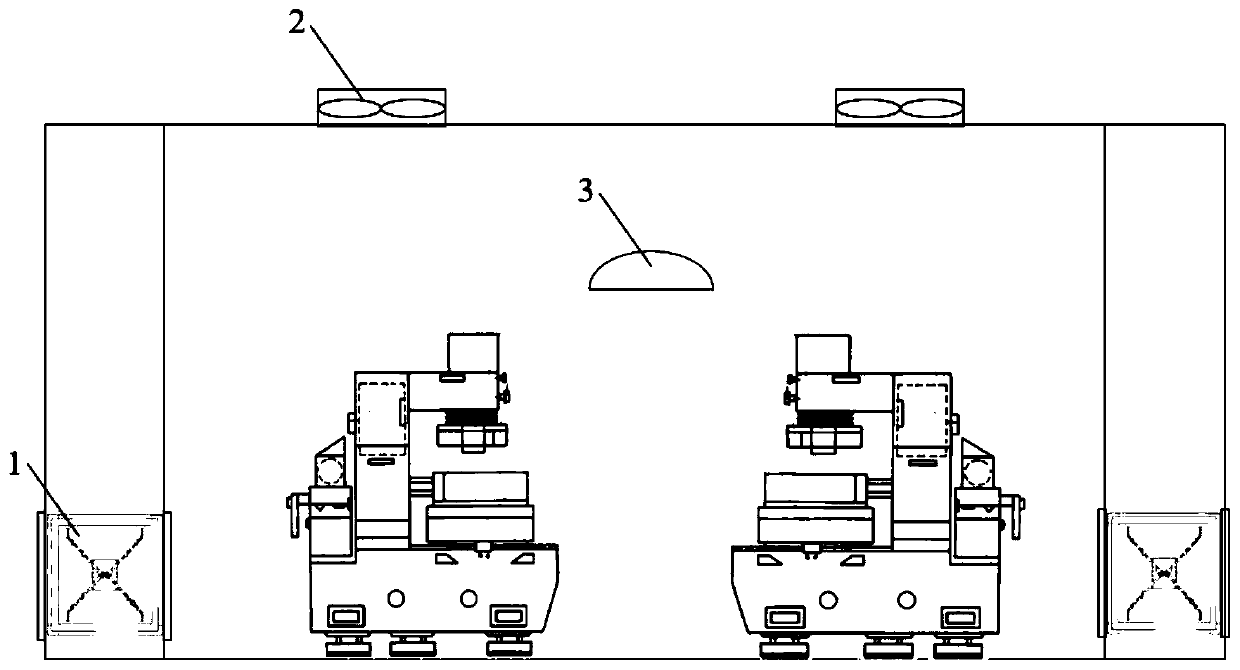

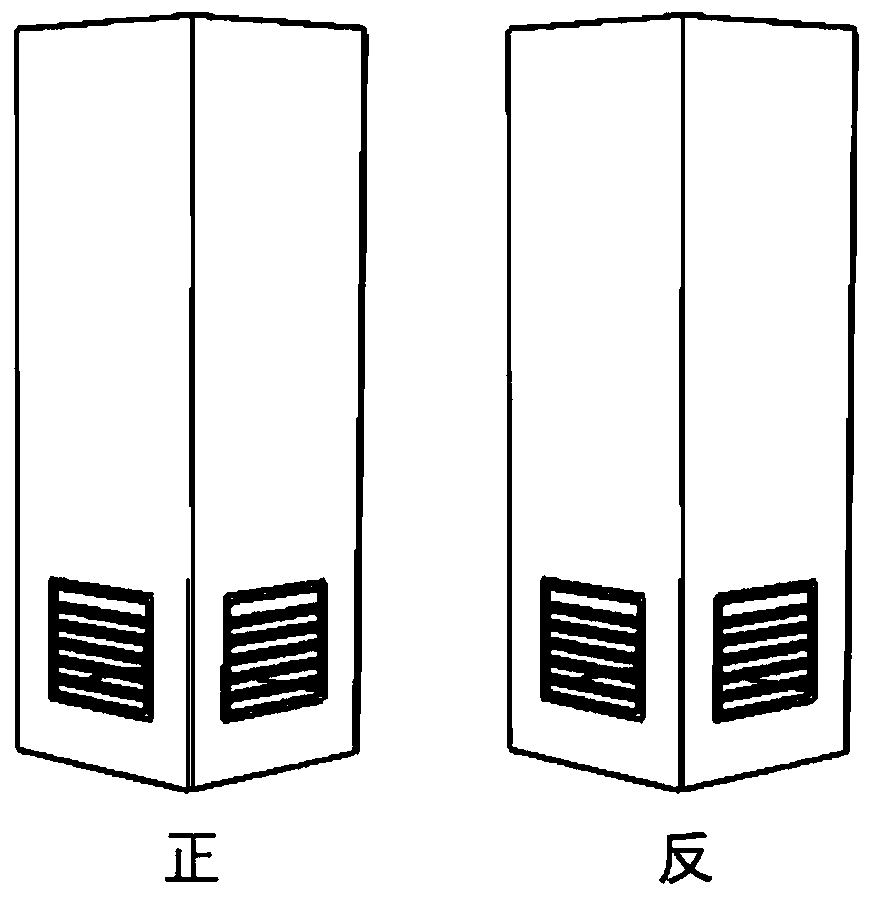

[0032] A ventilation and heating scheme suitable for high-pollution oil mist emission factory buildings in the present invention uses the original structural columns as air duct layout attachments inside the tall factory buildings to allow clean cold air to pass through the vents around the columns evenly When it flows into the factory building, it uses the principle of thermal buoyancy to drive the air up, and the fine aerodynamic properties of fine oil mist particles form a bottom-up displacement ventilation form that carries pollutants up and is discharged from the exhaust fan on the roof.

Embodiment 2

[0034] In order to verify the pollutant control effect of the column displacement ventilation provided by the present invention on the highly polluted oil mist emission factory building, a numerical model was established according to the actual factory conditions. 20m to 30m, evenly distributed in the factory building, the size of the air supply port is 1m×1.5m, the air supply speed is 1m / s, arranged around the column structure near the ground, the size of the roof exhaust device is 1m×1m, evenly arranged on the roof , the far-infrared auxiliary heater is above the production line, and the filament temperature is 400 °C. The ventilation effect of the present invention is judged by studying the average concentration of oil mist at the height of the breathing zone of the model.

[0035] In this verification, the turbulence model uses the RNG k-ε model based on Reynolds average, the difference format uses the second-order upwind style, and the SIMPLE algorithm is used to solve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com