Air outlet for precise control of air supply direction and method for realizing different airflow organization

A technology of precise control and airflow organization, applied in the directions of airflow control elements, heating methods, space heating and ventilation, etc., it can solve the problems of fixed installation position, difficult adjustment of the air supply direction, and single form of air supply outlet, and achieves the best installation method. Flexible position, reducing the risk of wind blowing, the effect of uniform low-speed air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

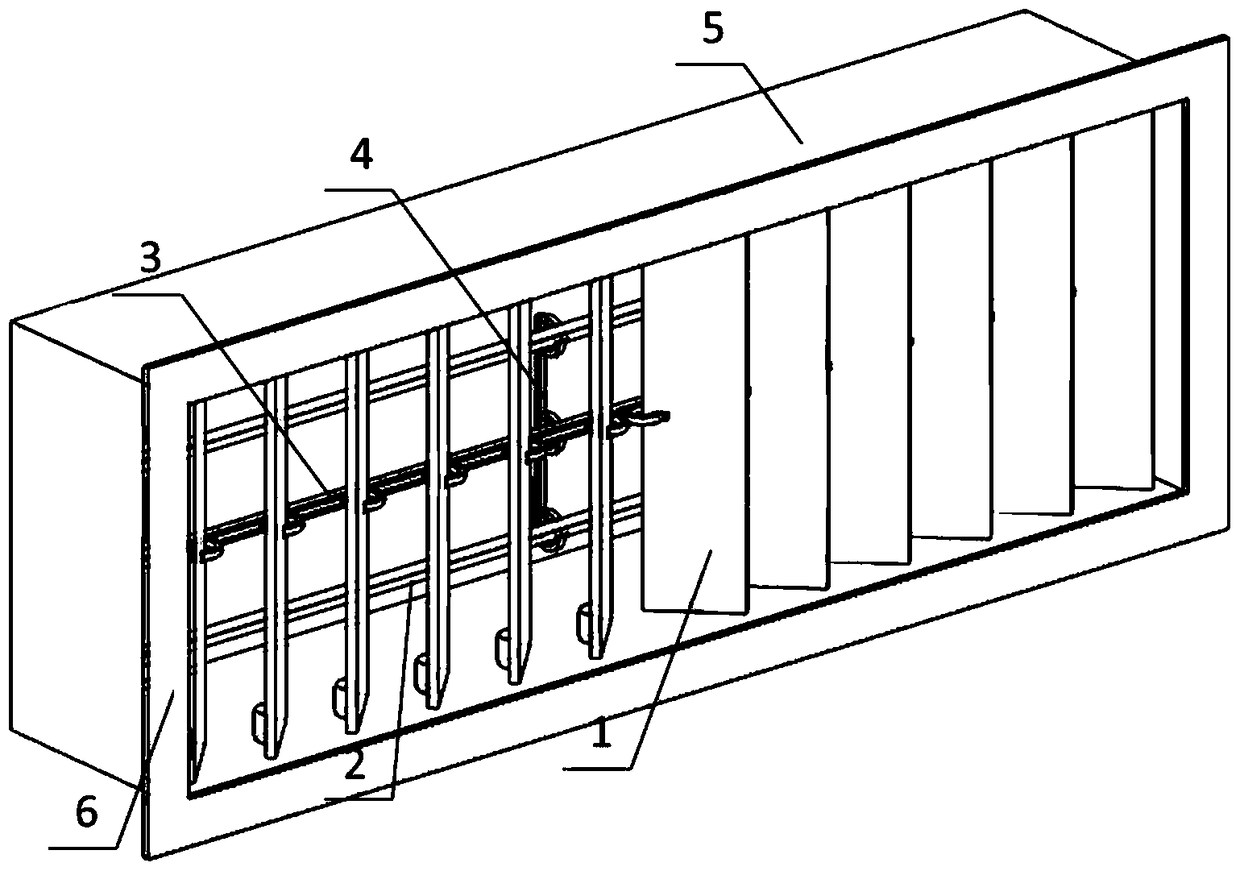

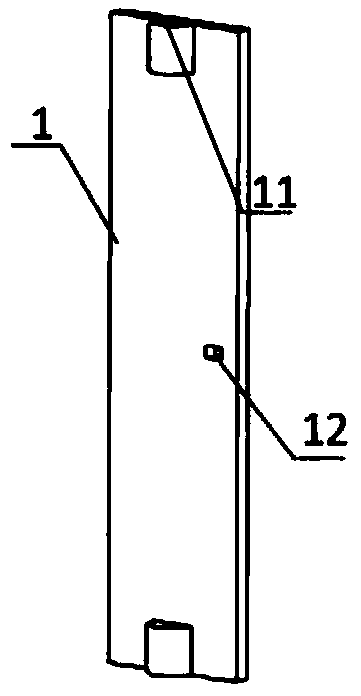

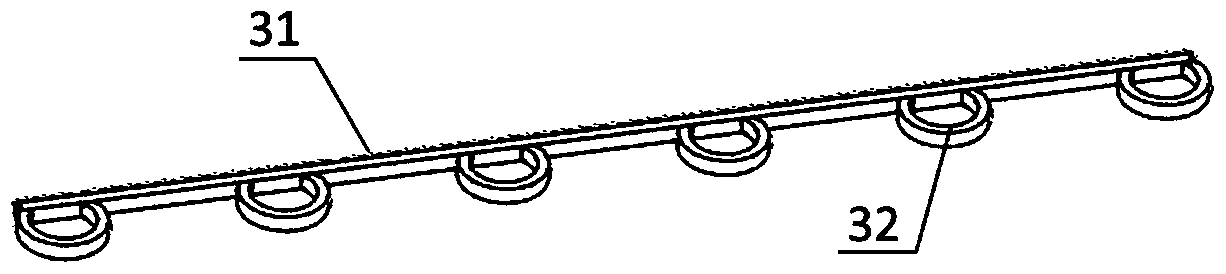

[0030] Such as Figure 1 to Figure 6 As shown, the present invention is an air supply port for precisely controlling the air supply direction, which includes a peripheral frame 5, and the peripheral frame 5 is provided with multiple rows of horizontally arranged first-stage blades 2 and multiple rows of vertically arranged secondary blades 1; all Both ends of the primary blade 2 and the secondary blade 1 are respectively connected in rotation with the peripheral frame 5; the rotation axes of all the secondary blades are on the same plane; The connecting rods 4 are connected to form a group of first-level louvers, and multiple rows of vertically arranged second-level blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com