A kind of niobium-containing 420 stainless steel material and its preparation method and application

A technology of stainless steel and mixed raw materials, which is used in transportation and packaging, metal processing equipment, surgical forceps, etc., can solve the problems of many surface and internal voids, affecting product qualification rate, and high process control requirements. It can improve the sintering window and inhibit liquid Phasor generation, the effect of widening the sintering window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

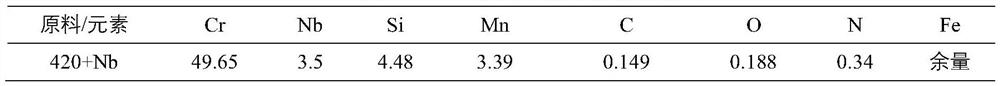

[0043] Mix niobium-containing master alloy (420+Nb) powder with a median particle size of 12.5 microns and 2.5 micron iron powder at a mass ratio of niobium-containing master alloy powder to iron powder of 2.6:1 to obtain mixed raw material powder , and then mix the mixed raw material powder with the wax-based binder, the mass ratio of the mixed raw material powder to the binder is 57.86:42.14, the internal mixer is used for mixing, the mixing temperature is 150 ° C, the internal mixer speed The mixing time is 60r / min, the mixing time is 1.5h, and the feeding material is made after cooling and crushing.

[0044] Put the prepared feed into the BOY50T injection molding machine, the injection temperature is 155°C, the injection pressure is 60Mpa, the mold temperature is controlled at room temperature -50°C, and the blank is injection molded.

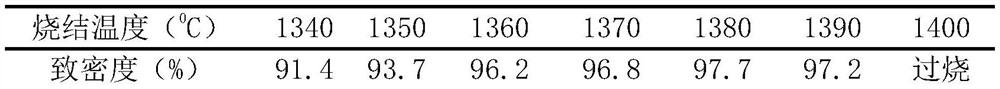

[0045] Then place the blank in a dichloromethane solvent to dissolve the paraffin and vegetable oil components; then put the dried blank i...

Embodiment 2

[0048] Mix niobium-containing master alloy (420+Nb) powder with a median particle size of 12.5 microns and 2.5 micron iron powder at a mass ratio of niobium-containing master alloy powder to iron powder of 2.6:1 to obtain mixed raw material powder , and then mix the mixed raw material powder with the wax-based binder, the mass ratio of the mixed raw material powder to the binder is 57.86:42.14, the internal mixer is used for mixing, the mixing temperature is 150 ° C, the internal mixer speed The mixing time is 60r / min, the mixing time is 1.5h, and the feeding material is made after cooling and crushing.

[0049] Put the prepared feed into the BOY50T injection molding machine, the injection temperature is 155°C, the injection pressure is 60Mpa, the mold temperature is controlled at room temperature -50°C, and the blank is injection molded.

[0050] Then place the blank in a dichloromethane solvent to dissolve the paraffin and vegetable oil components; then put the dried blank i...

Embodiment 3

[0053] Mix niobium-containing master alloy (420+Nb) powder with a median particle size of 12.5 microns and 2.5 micron iron powder at a mass ratio of niobium-containing master alloy powder to iron powder of 2.6:1 to obtain mixed raw material powder , and then mix the mixed raw material powder with the wax-based binder, the mass ratio of the mixed raw material powder to the binder is 57.86:42.14, the internal mixer is used for mixing, the mixing temperature is 150 ° C, the internal mixer speed The mixing time is 60r / min, the mixing time is 1.5h, and the feeding material is made after cooling and crushing.

[0054] Put the prepared feed into the BOY50T injection molding machine, the injection temperature is 155°C, the injection pressure is 60Mpa, the mold temperature is controlled at room temperature -50°C, and the blank is injection molded.

[0055] Then place the blank in a dichloromethane solvent to dissolve the paraffin and vegetable oil components; then put the dried blank i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com