Environment-friendly degumming agent as well as preparation method and application thereof

An environment-friendly glue technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of material surface damage, high toxicity of glue remover, and secondary pollution of the environment, and it is not easy to achieve Combustion and fire, wide application range, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

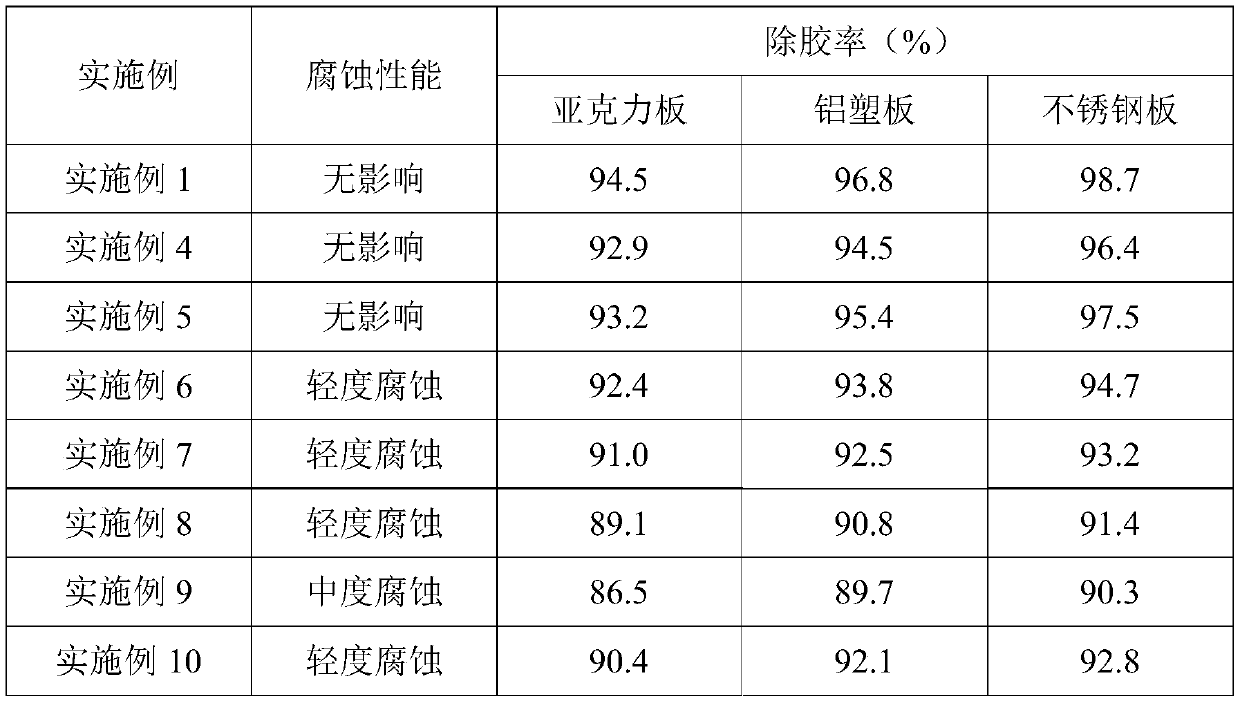

Examples

preparation example Construction

[0041] The second aspect of the present invention provides a kind of preparation method of described environment-friendly adhesive remover, and step comprises at least:

[0042] (1) Add limonene, penetrant, and deodorizing hydrocarbon solvent into the reaction kettle for stirring, and heat up to 50-80°C while stirring, and then keep stirring for 30-60 minutes; (2) Add the remaining raw materials in turn, and continue stirring for 15 -45 minutes; (3) After the stirring is completed, let it stand for defoaming for 5-12 hours, and then pack it.

[0043] In some preferred embodiments, the preparation method of the environment-friendly glue remover, the steps at least include:

[0044] (1) Add limonene, penetrant, and deodorizing hydrocarbon solvent into the reaction kettle for stirring, and heat up to 60-75°C while stirring, and then keep stirring for 40-50 minutes; (2) Add the remaining raw materials in sequence, and continue stirring for 25 -40 minutes; (3) after the stirring i...

Embodiment 1

[0050] A kind of environment-friendly adhesive remover, by weight, raw material comprises, 65 parts of D-limonene, 35 parts of deodorized hydrocarbon solvents, 12 parts of penetrating agents, 7 parts of surfactants, 10 parts of dibasic acid esters, 60 parts of water .

[0051] The deodorized hydrocarbon solvent is D110 solvent, purchased from Shanghai Huishuo Chemical Co., Ltd. The penetrating agent is ethylene glycol methyl ether. The surfactant is selected from coconut oil glycol amide. The dibasic acid methyl ester monomer is selected from the combination of dimethyl succinate, dimethyl glutarate and dimethyl adipate, and the dimethyl succinate, dimethyl glutarate, adipate The ratio of dimethyl diacid is 1:0.8:0.25. The raw material also includes a polyether derivative with an amino group; the amount of the polyether derivative with an amino group is 12% of the quality of limonene, and the polyether derivative with an amino group is 4-aminobutyraldehyde Diethyl acetal a...

Embodiment 2

[0054] A kind of environment-friendly adhesive remover, by weight, raw material comprises, 55 parts of D-limonene, 25 parts of deodorized hydrocarbon solvents, 5 parts of penetrating agents, 5 parts of surfactants, 5 parts of dibasic acid esters, 30 parts of water .

[0055] The deodorized hydrocarbon solvent is D80 solvent, purchased from Shanghai Huishuo Chemical Co., Ltd. The penetrating agent is tripropylene glycol methyl ether. The surfactant is selected from diisooctyl sodium sulfosuccinate. The dibasic acid methyl ester monomer is selected from the combination of dimethyl succinate, dimethyl glutarate and dimethyl adipate, and the dimethyl succinate, dimethyl glutarate, adipate The ratio of dimethyl diacid is 1:0.5:0.1. The raw material also includes a polyether derivative with an amino group; the amount of the polyether derivative with an amino group is 5% of the quality of limonene, and the polyether derivative with an amino group is 4-aminobutyraldehyde Diethyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com