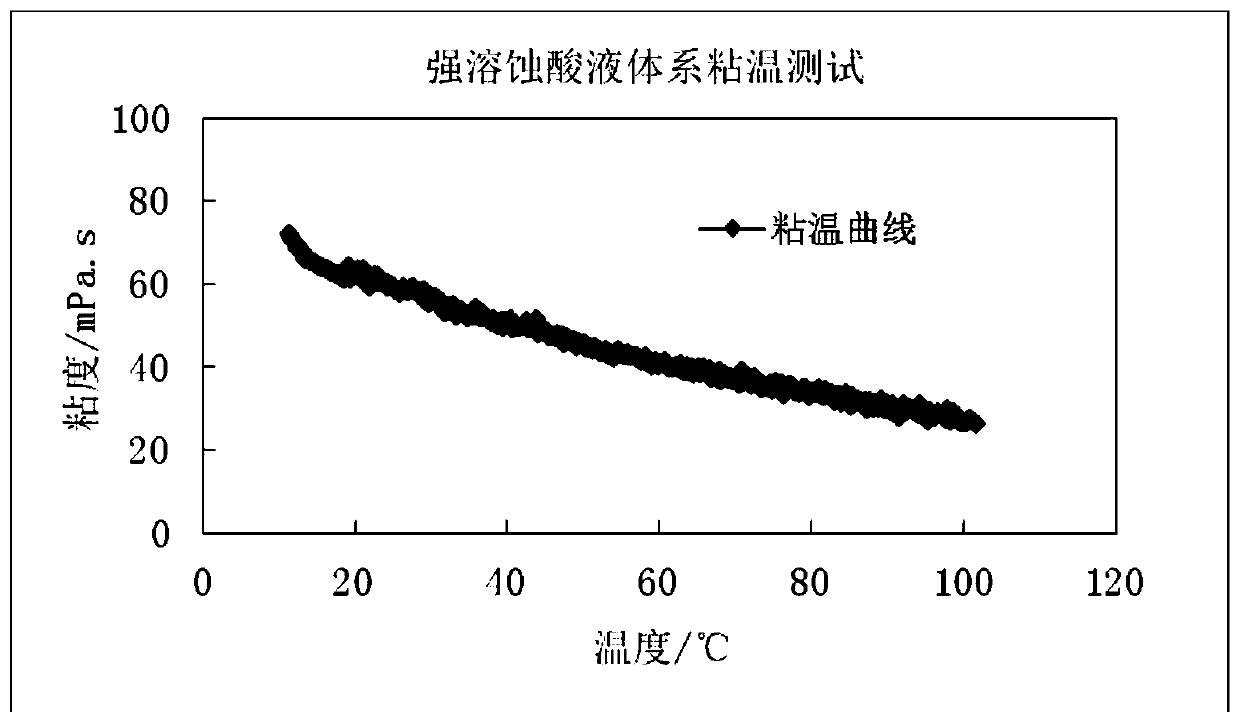

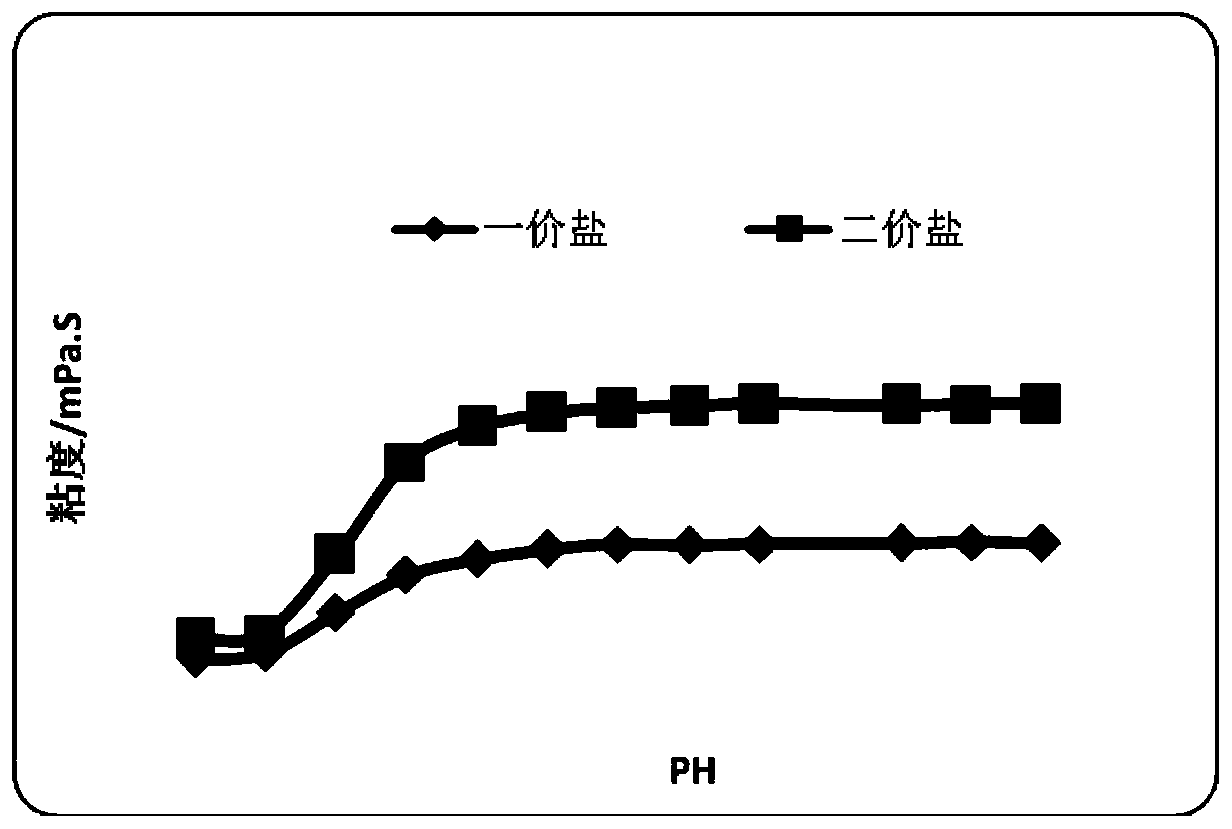

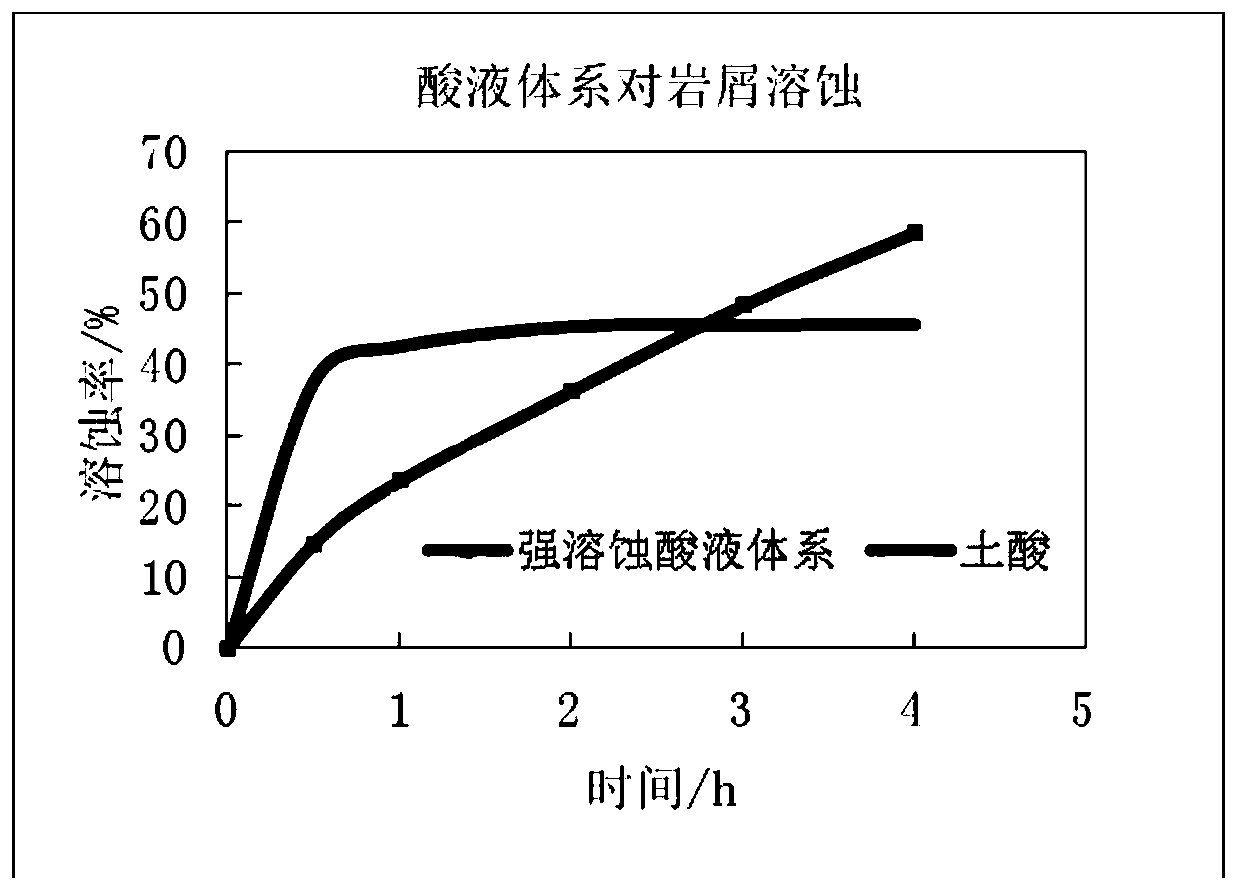

High-viscosity strong-corrosion acid liquid system for low-permeability sandstone oil reservoir

A high-viscosity technology for sandstone reservoirs, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced production, increased production and increased injection, unsatisfactory effects of increased production, and increased scaling caused by reservoir blockages. To achieve the effect of increasing the effective distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A low-permeability sandstone reservoir high-viscosity strong corrosion acid solution system, comprising:

[0032] 6% hydrochloric acid, 1% betaine, 4% enhancer, 0.05% citric acid, 0.5% ammonium chloride, 0.5% corrosion inhibitor, 0.1% drainage aid, 0.05% demulsifier, the balance is water, the above groups The sum of the points is 100%;

[0033] The enhancer is a JD-30B enhancer;

[0034] Described corrosion inhibitor is sodium nitrate;

[0035] The drainage aid is polyoxyethylene fatty acid ester;

[0036] Described demulsifier is demulsifier MQ801.

Embodiment 2

[0038] A low-permeability sandstone reservoir high-viscosity strong corrosion acid solution system, comprising:

[0039] 12% hydrochloric acid, 3% betaine, 8% enhancer, 0.2% citric acid, 2% ammonium chloride, 2% corrosion inhibitor, 0.4% drainage aid, 0.2% demulsifier, the balance is water, the above groups The sum of the points is 100%;

[0040] The enhancer is a JD-30B enhancer;

[0041] The corrosion inhibitor is potassium fluoride;

[0042] The drainage aid is polyoxyethylene alkylamine;

[0043] Described demulsifier is demulsifier MQ801.

Embodiment 3

[0045] A low-permeability sandstone reservoir high-viscosity strong corrosion acid solution system, comprising:

[0046] 8%% hydrochloric acid, 1% betaine, 5% JD-30B enhancer, 0.05% citric acid, 0.5% ammonium chloride, 0.5% sodium nitrate, 0.2% polyoxyethylene alkylamide, 0.05% demulsifier MQ801, the rest The amount is water, and the sum of the above components is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com