Double-sided pressure-sensitive explosive tape and preparation method thereof

A pressure-sensitive explosive and pressure-sensitive adhesive technology, used in explosives processing equipment, explosives, non-explosive fillers/gelling agents/thickeners, etc., can solve the problems of low strength, poor adhesion performance of flexible explosives, and achieve hardening High efficiency, good explosion effect and uniform explosion impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

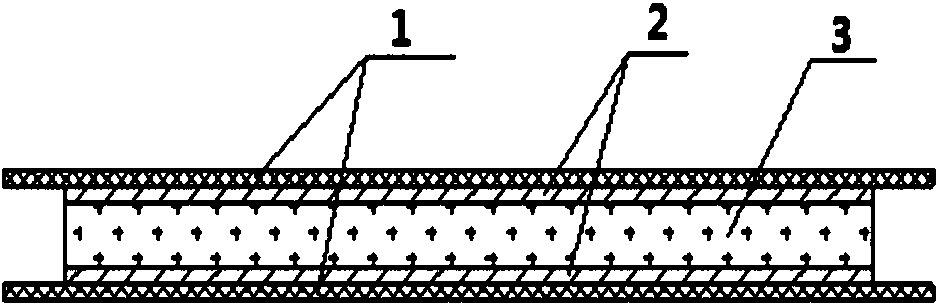

[0021] A double-sided pressure-sensitive explosive adhesive tape, comprising a flexible explosive layer 3, pressure-sensitive adhesive layers 2 are coated on the upper and lower sides of the flexible explosive layer 3, and pressure-sensitive adhesive layers 2 are coated on the outer surfaces of the pressure-sensitive adhesive layers 2 on both sides. Attached with a release material layer 1, its structure is as follows figure 1 shown.

[0022] The flexible explosive layer 3 is made by mixing a polymer material binder and a simple high explosive. The polymer material binder is made by mixing natural rubber / latex and polymethyl acrylate, and the single-mass explosive uses PETN. The thickness of the flexible explosive layer is 0.8mm.

[0023] The pressure-sensitive adhesive layer 2 is made of acrylate pressure-sensitive adhesive, and its thickness is 25 μm.

[0024] The release material layer 1 adopts a release film.

[0025] The preparation method of the above-mentioned doubl...

Embodiment 2

[0028] A double-sided pressure-sensitive explosive adhesive tape, comprising a flexible explosive layer 3, the upper and lower sides of the flexible explosive layer 3 are coated with a pressure-sensitive adhesive layer 2, and the outer surface of the pressure-sensitive adhesive layer 2 on one side is Both are attached with a release material layer 1, and its structure is as follows figure 2 shown.

[0029] The flexible explosive layer 3 is made by mixing a polymer material binder and a simple high explosive. The polymer material binder is made by mixing natural rubber / latex and polymethyl acrylate, and the single-substance high explosive uses RDX. The thickness of the flexible explosive layer is 1.2mm.

[0030] The pressure-sensitive adhesive layer 2 is made of acrylate pressure-sensitive adhesive, and its thickness is 20 μm.

[0031] The release material layer 1 adopts release paper.

[0032] The preparation method of the above-mentioned double-sided pressure-sensitive e...

Embodiment 3

[0035] A double-sided pressure-sensitive explosive adhesive tape, comprising a flexible explosive layer 3, pressure-sensitive adhesive layers 2 are coated on the upper and lower sides of the flexible explosive layer 3, and pressure-sensitive adhesive layers 2 are coated on the outer surfaces of the pressure-sensitive adhesive layers 2 on both sides. A release material layer 1 is attached.

[0036] The flexible explosive layer 3 is made by mixing a polymer material binder and a simple high explosive. The polymer material binder is made by mixing natural rubber / latex and polymethyl acrylate, and the single-mass explosive uses HMX. The thickness of the flexible explosive layer is 1.0mm.

[0037] The pressure-sensitive adhesive layer 2 is made of acrylate pressure-sensitive adhesive, and its thickness is 30 μm.

[0038] The release material layer 1 adopts a release film.

[0039]The preparation method of the above-mentioned double-sided pressure-sensitive explosive adhesive tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com