A martensitic stainless steel continuous annealing pickling line welding method

A technology of martensitic stainless steel and welding methods, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of easy cracking of welds, avoid weld fractures, avoid cracking of annealing and pickling lines, and increase protection intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

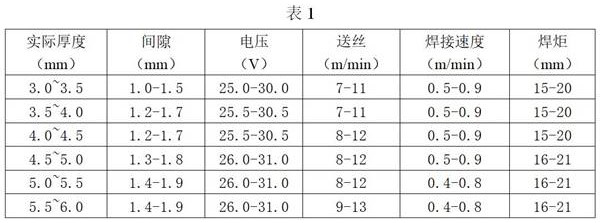

[0022] The specific MIG welding parameters for 50Cr15MoV stainless steel are shown in Table 1.

[0023]

[0024] The annealing and pickling line requires two volumes of annealed 50Cr15MoV stainless steel with a thickness of 5.0mm before and after welding. First, the welding seam 1 of the steel coil is formed by welding with the corresponding parameters in Table 1 according to the thickness of the steel coil. The welding wire is 309Si and the specification is 1.2mm.

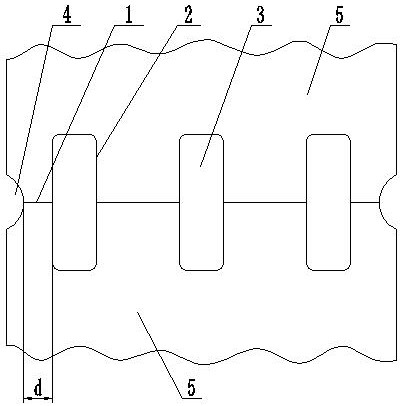

[0025] Rib plate 3 is prepared in advance, the material is 304 annealed, the welding rod material is 309L, and the specification is 2.5*350mm. Ribs 3 have the same size, the specific specification is 4.0 (thickness) * 100 * 300mm, and the surrounding is arc-shaped, the arc radius is 10mm, to avoid stress concentration cracking at the corner, the specific shape is as follows figure 1 shown.

[0026] Use a shearing device with a crescent-shaped incision to cut off the arc-starting and arc-ending sections of the...

Embodiment 2

[0033] The annealing and pickling line requires two volumes of annealed 50Cr15MoV stainless steel with a thickness of 3.0mm before and after welding. First, weld the weld seam 1 of the steel coil with the corresponding parameters in Table 1 according to the thickness of the steel coil. The welding wire is 309Si and the specification is 1.2mm.

[0034] Prepare the rib plate 3 in advance, the material is 304 annealed state, the size of the rib plate 3 is the same, the specific specification is 1.5 (thickness)*100*300mm, and the surrounding is arc-shaped, the radius of the arc is 5mm, to avoid stress concentration cracking at the corner , the specific form is as figure 1 shown.

[0035] Use a shearing device with a crescent-shaped incision to cut off the arc-starting and arc-ending sections of the weld 1 of the steel coil to avoid poor formation of these two places, which will cause cracks to occur first in the arc-starting and arc-ending sections during the operation of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com