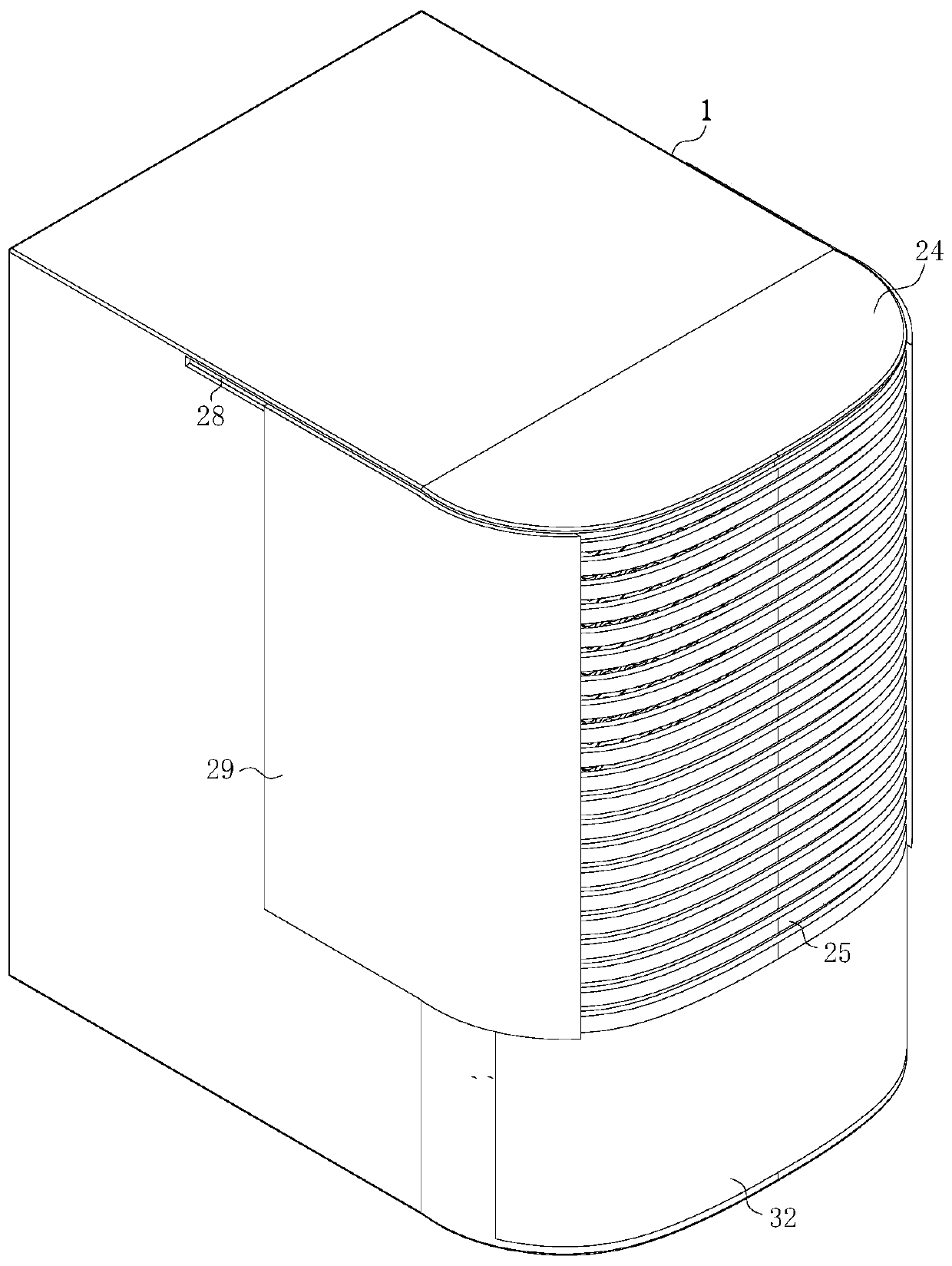

Precise air cooler fan blade and casting process thereof

A cooling fan and fan blade technology, which is used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of small contact area between water and air, limited water vaporization effect, and large air resistance of fan blades. Labor cost, strong cooling effect, and the effect of reducing rotational noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] As an embodiment of the present invention, a groove is provided on the arc surface of the rotating hole; an O-ring 33 is provided inside the groove, and the O-ring 33 is rotatably connected to the output shaft of the motor 15; During work, when the air flow cavity is full of atomized water, the atomized water will easily enter the inside of the sleeve 13 through the rotating hole and the output shaft of the motor 15, and then the motor 15 will be soaked, which will affect the normal use of the motor 15, and even make the motor 15 15 is short-circuited and burned, so by setting an O-ring 33 in the rotating hole, the output shaft of the motor 15 is connected to the O-ring 33 in rotation, and the inside of the sleeve 13 can be isolated from the air flow chamber, effectively preventing water from entering The inside of the sleeve 13 realizes the protection of the motor 15 .

[0030] As an embodiment of the present invention, an arc-shaped dome 34 is fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com