Sludge discharge system of secondary sedimentation tank and operation method thereof

An operation method and technology of mud system, applied in separation method, chemical instrument and method, sedimentation tank, etc., can solve the problems of increasing construction period and construction difficulty, large depth of sludge return well, increasing energy consumption, etc., so as to reduce construction Difficulty and risk, saving construction area, reducing the effect of excess sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

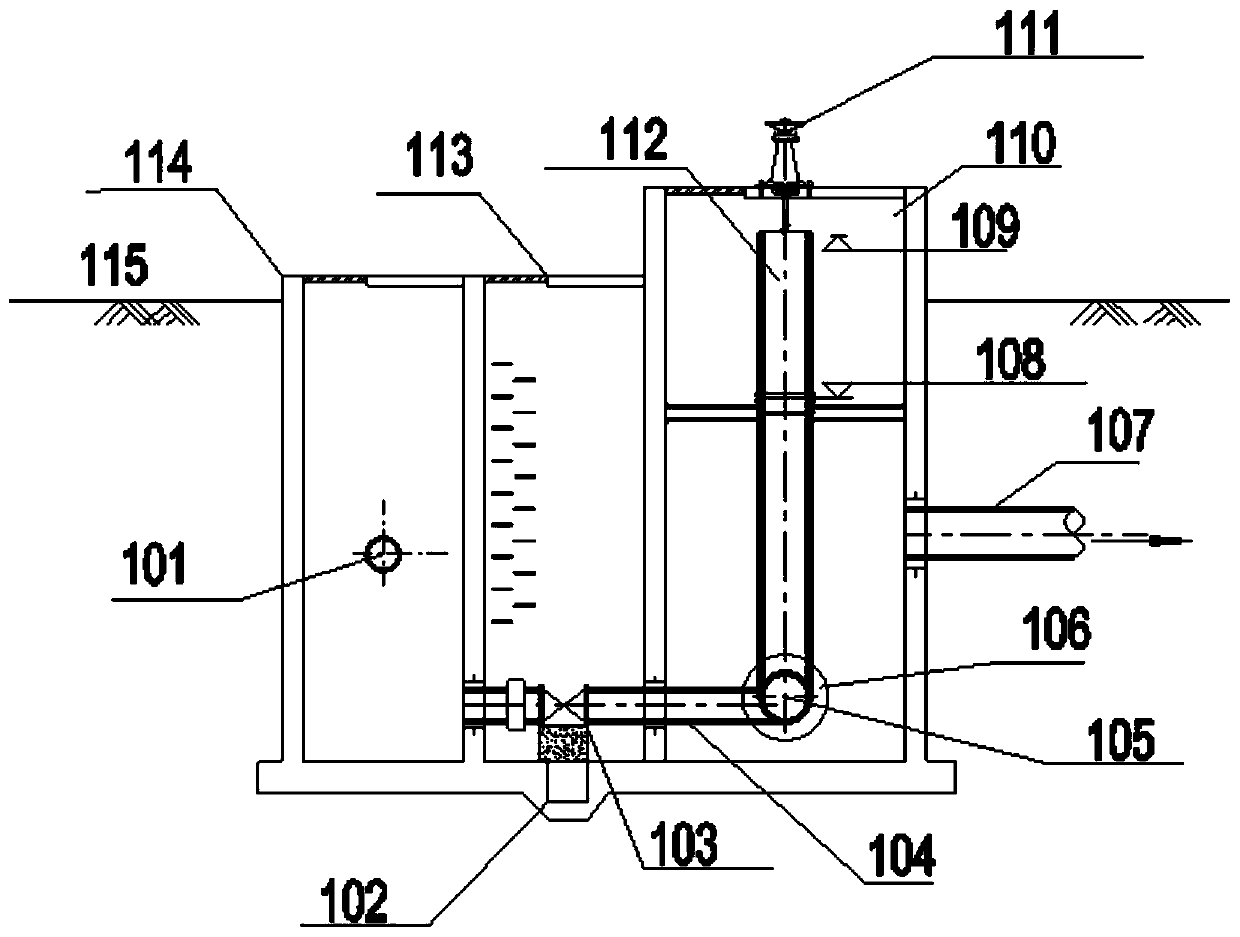

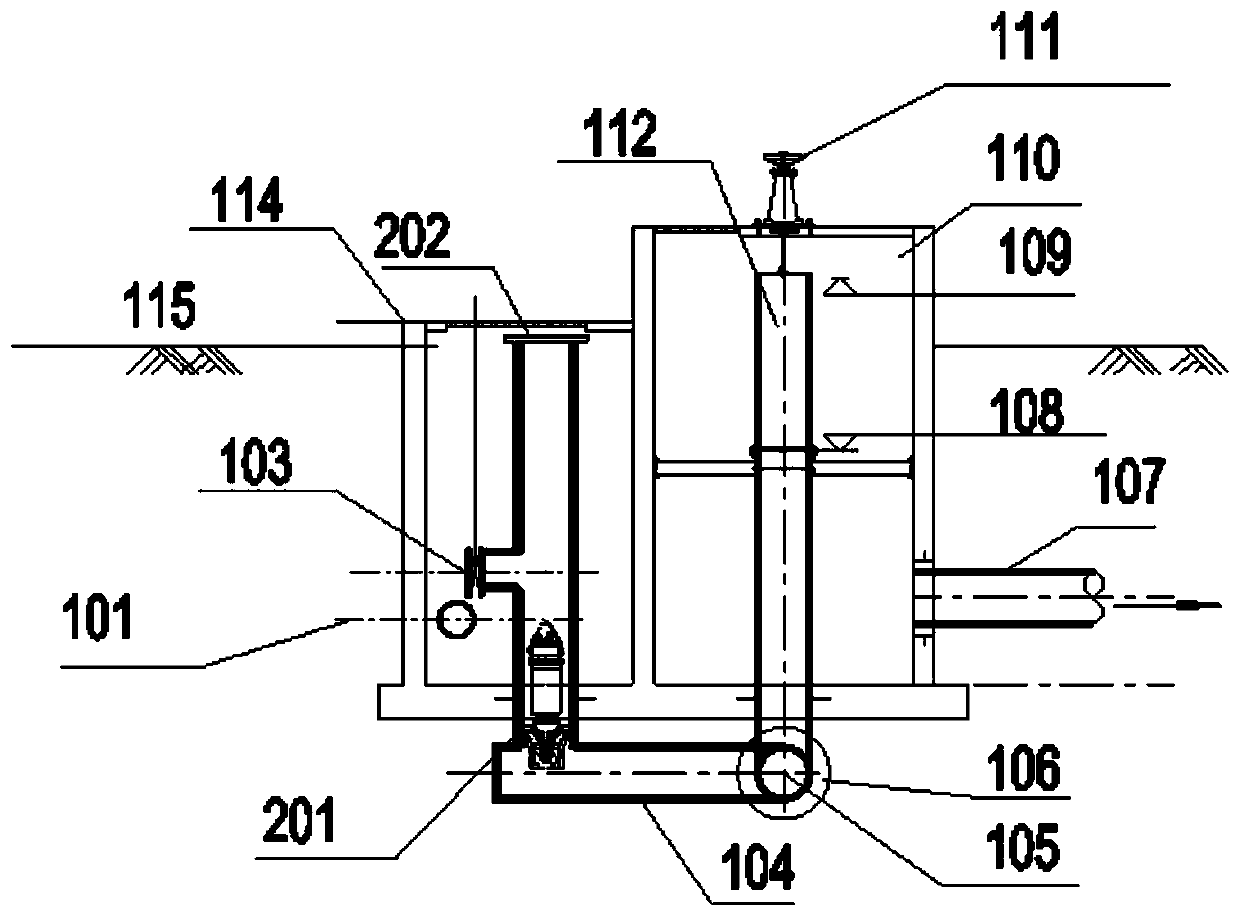

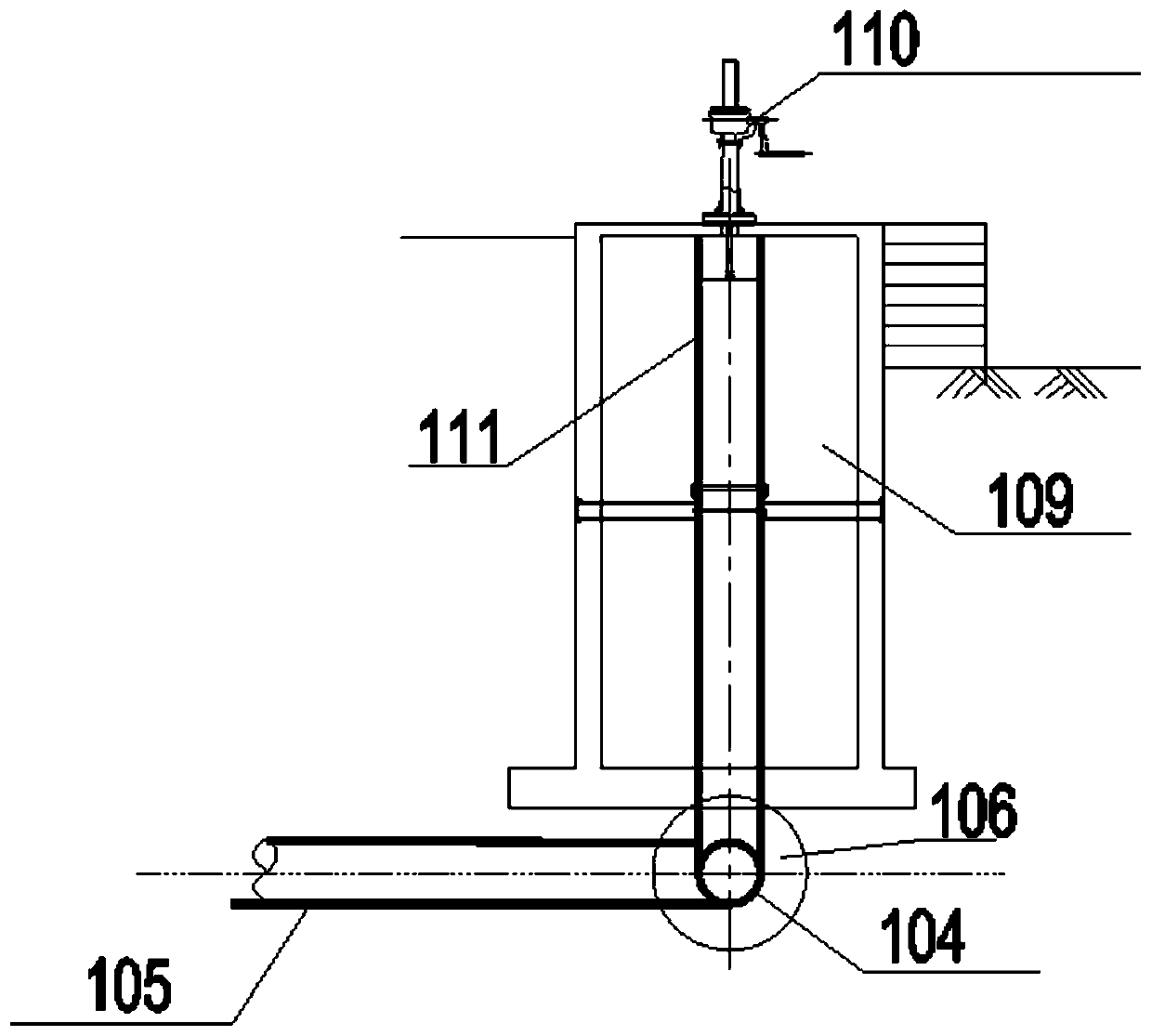

[0040] figure 2 Shown is a schematic structural diagram of a secondary settling tank sludge discharge system, the secondary settling tank system includes a drain pipe 101, a gate valve 103, a vent pipe 104, a sludge discharge main pipe 105, a tee 106, a sludge return pipe 107, and a sleeve The lowest valve port 108, the highest valve port of the sleeve valve 109, the sludge return well 110, the manual screw hoist 111, the sleeve valve 112, the vent well 114, the ground 115, the axial flow pump 201, and the pump cylinder 202.

[0041] An extension rod is installed on the gate valve 103, so that the technician needn't enter the venting well to ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com