Inorganic bearing purline bearing built-up roof and floor

A technology of recombination and purlins, which is applied to roofs, floors, building components, etc., can solve the problems of high production, transportation, and installation costs, inconvenient batch mechanical construction production, product volume, and large area, etc., to reduce installation labor costs , convenient transportation and installation, and the effect of reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

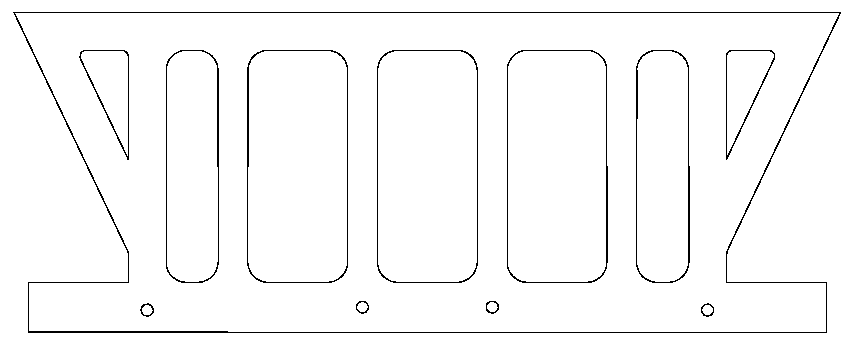

[0034] Combine below figure 1 Describe in detail the technical scheme of the inorganic load-bearing purlin load-bearing composite roof floor:

[0035] A load-bearing composite roof floor with inorganic load-bearing purlins, including inorganic load-bearing purlins 1, the inorganic load-bearing purlins 1 adopt inorganic materials to vacuum-extrude the hollow body, when the purlins are extruded, they will be on the plane of the bottom end plate of the inorganic load-bearing purlins 1 Steel bars or fiber tows 4 are evenly distributed in the middle position. After the inorganic load-bearing purlin is solidified and dried, the inorganic load-bearing purlin 1 is filled with thermal insulation and / or sound-absorbing materials 5, and the bottom ends of the inorganic load-bearing purlin 1 are horizontally and / or The side ends are fixedly connected by welding or bolts to connect the steel plates 3 or section steel, and the connection steel plates 3 or section steel at the bottom ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com