Paper impregnating device for producing glue film paper

An impregnating device and adhesive film technology, applied in paper, papermaking, physical treatment of paper, etc., can solve the problems of wasting glue, inability to absorb paper dust, and inability to dry efficiently, so as to improve production efficiency, high drying efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

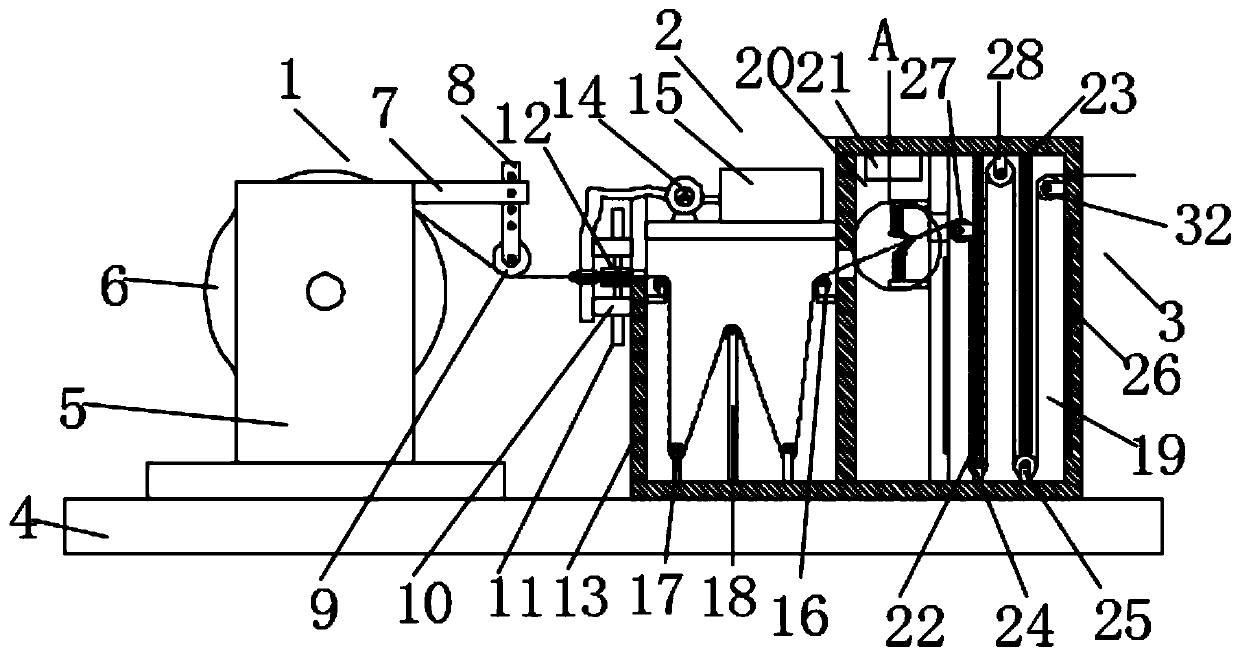

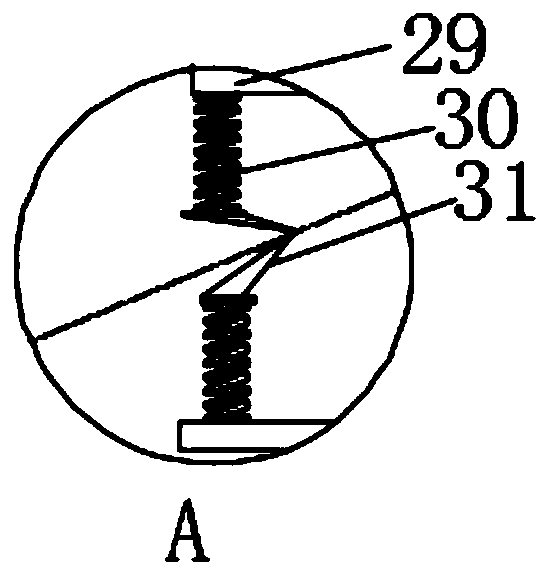

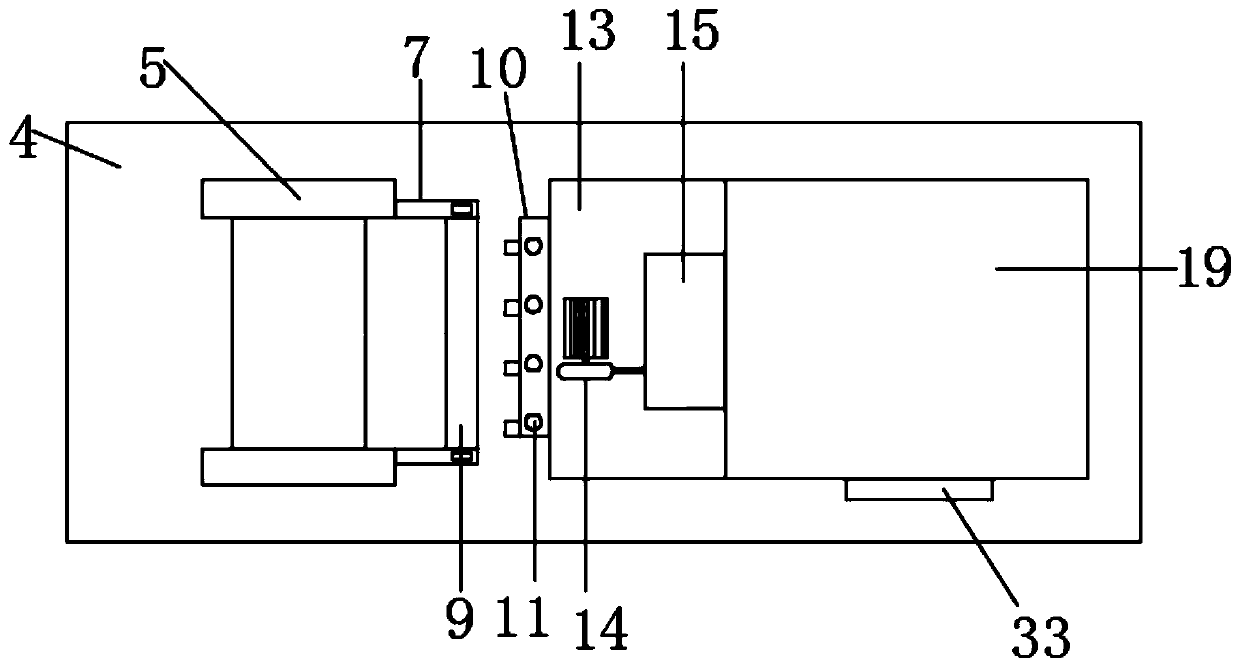

[0020] Example: such as Figure 1-3 As shown, a paper impregnation device for adhesive film paper production of the present invention includes a cleaning mechanism 1, an impregnation mechanism 2, and a drying mechanism 3. The cleaning mechanism 1 is composed of a bottom support plate 4, a support support plate 5, and a material roller 6. , The balance support rod 7, the height adjustment rod 8, the first conveying roller 9, the fixed support seat 10, the pitch adjustment cylinder 11, the cleaning brush 12, the immersion box 13, the cleaning fan 14 and the dust box 15, the bottom support The top end of the plate 4 is fixedly connected with two supporting support plates 5, a material roller 6 is rotatably connected between the two supporting support plates 5, and a balance support rod 7 is fixedly connected to one end of the two supporting support plates 5 , The end of the balance support rod 7 away from the support support plate 5 is connected with a height adjustment rod 8 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com