Superhydrophobic coating layer with adjustable particle concentration, and preparation method thereof

A particle concentration, super-hydrophobic technology, applied in the direction of coating, etc., can solve the problems of cumbersome and complicated production process, expensive raw materials, unstable modification performance of hydrophobic particles, etc., to avoid process instability, reduce tediousness, particle Concentration range requires broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

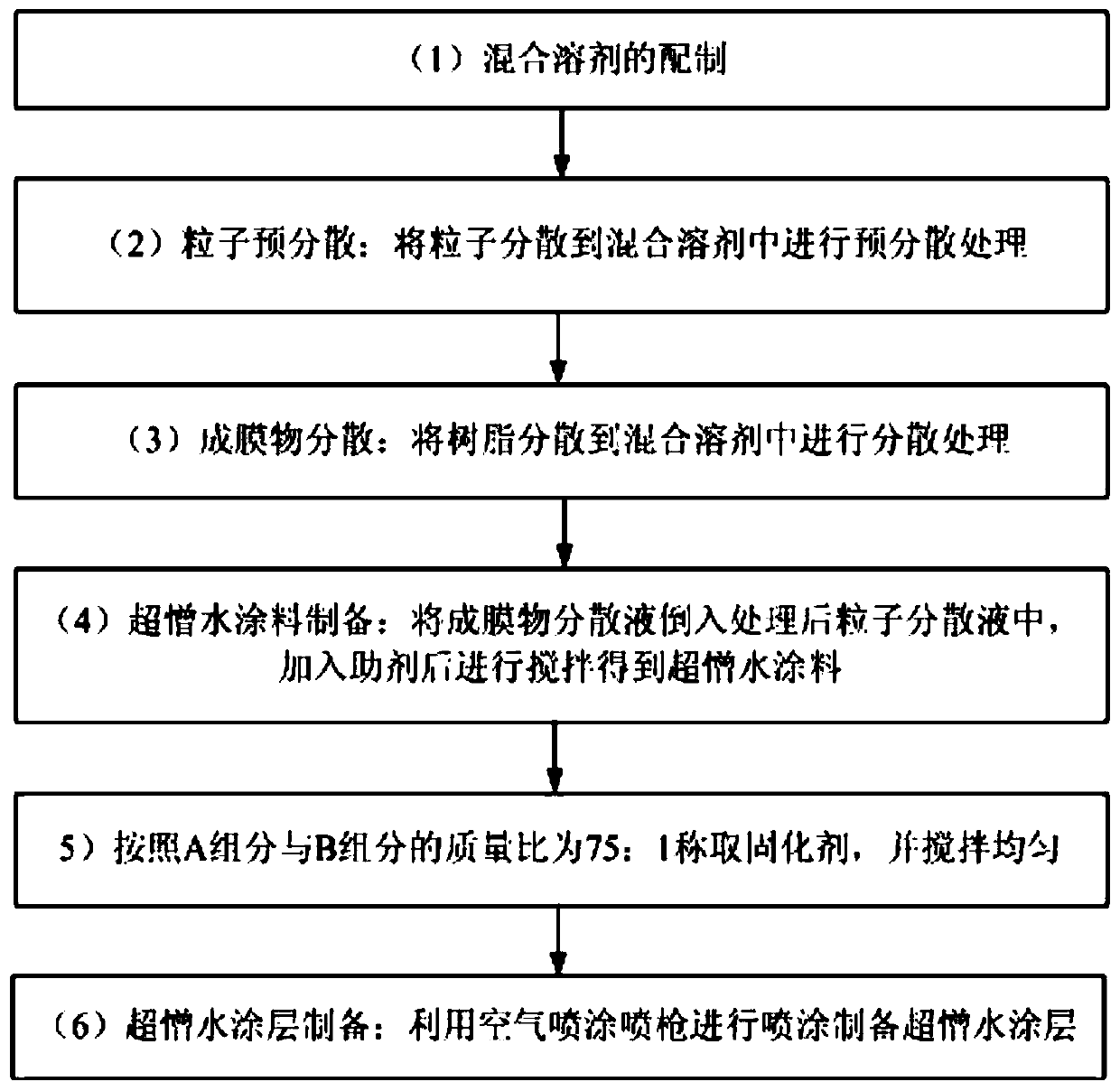

[0031] A super-hydrophobic coating with adjustable particle concentration (modified fluorocarbon topcoat), which is composed of component A and component B, and the mass ratio of component A to component B is 75:1; The A component is composed of the following raw materials by weight: silicone resin: 13 parts, organic solvent: 81.1 parts, silicon oxide: 3.9 parts, dispersant: 0.5 part, defoamer: 0.5 part, leveling agent: 1 part; the B component is a silicone resin curing agent. like figure 1 As shown, the preparation steps of the modified fluorocarbon topcoat described in this embodiment are as follows:

[0032] (1) preparation of mixed solvent: according to the selected mass ratio, and according to the mass ratio of ethyl acetate and butyl acetate, the solvent is taken by weighing 3:2, and stirring is uniform;

[0033] (2) Particle pre-dispersion: Weigh the particles according to the selected mass ratio, and disperse them into part of the mixed solvent, and conduct pre-dispe...

Embodiment 2

[0039] A super-hydrophobic coating with adjustable particle concentration (modified fluorocarbon topcoat), which is composed of component A and component B, and the mass ratio of component A to component B is 75:1; The A component is composed of the following raw materials by weight: silicone resin: 13 parts, organic solvent: 80.34 parts, silicon oxide: 4.16 parts, dispersant: 0.7 parts, defoamer: 0.5 parts, leveling agent: 1.3 parts part; the B component is a silicone resin curing agent.

[0040] like figure 1 As shown, the preparation steps of the modified fluorocarbon topcoat described in this embodiment are as follows:

[0041] (1) preparation of mixed solvent: according to the selected mass ratio, and according to the mass ratio of ethyl acetate and butyl acetate, the solvent is taken by weighing 3:2, and stirring is uniform;

[0042] (2) Particle pre-dispersion: Weigh the particles according to the selected mass ratio, and disperse them into part of the mixed solvent, ...

Embodiment 3

[0048] A super-hydrophobic coating with adjustable particle concentration (modified fluorocarbon topcoat), which is composed of component A and component B, and the mass ratio of component A to component B is 75:1; The A component is composed of the following raw materials by weight: silicone resin: 13 parts, organic solvent: 79.95 parts, silicon oxide: 4.55 parts, dispersant: 0.8 parts, defoamer: 0.5 parts, leveling agent: 1.2 parts part; the B component is a silicone resin curing agent.

[0049] like figure 1As shown, the preparation steps of the modified fluorocarbon topcoat described in this embodiment are as follows:

[0050] (1) preparation of mixed solvent: according to the selected mass ratio, and according to the mass ratio of ethyl acetate and butyl acetate, the solvent is taken by weighing 3:2, and stirring is uniform;

[0051] (2) Particle pre-dispersion: Weigh the particles according to the selected mass ratio, and disperse them into part of the mixed solvent, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com