Preparation method and application of modified brominated butyl rubber porous material

A technology of bromobutyl rubber and porous materials, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of difficult to control the shape and size of pore structure, lack of crack resistance and Self-healing ability and other issues, to achieve the effect of simple, controllable and environmentally friendly operation process, excellent anti-crack performance, and enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

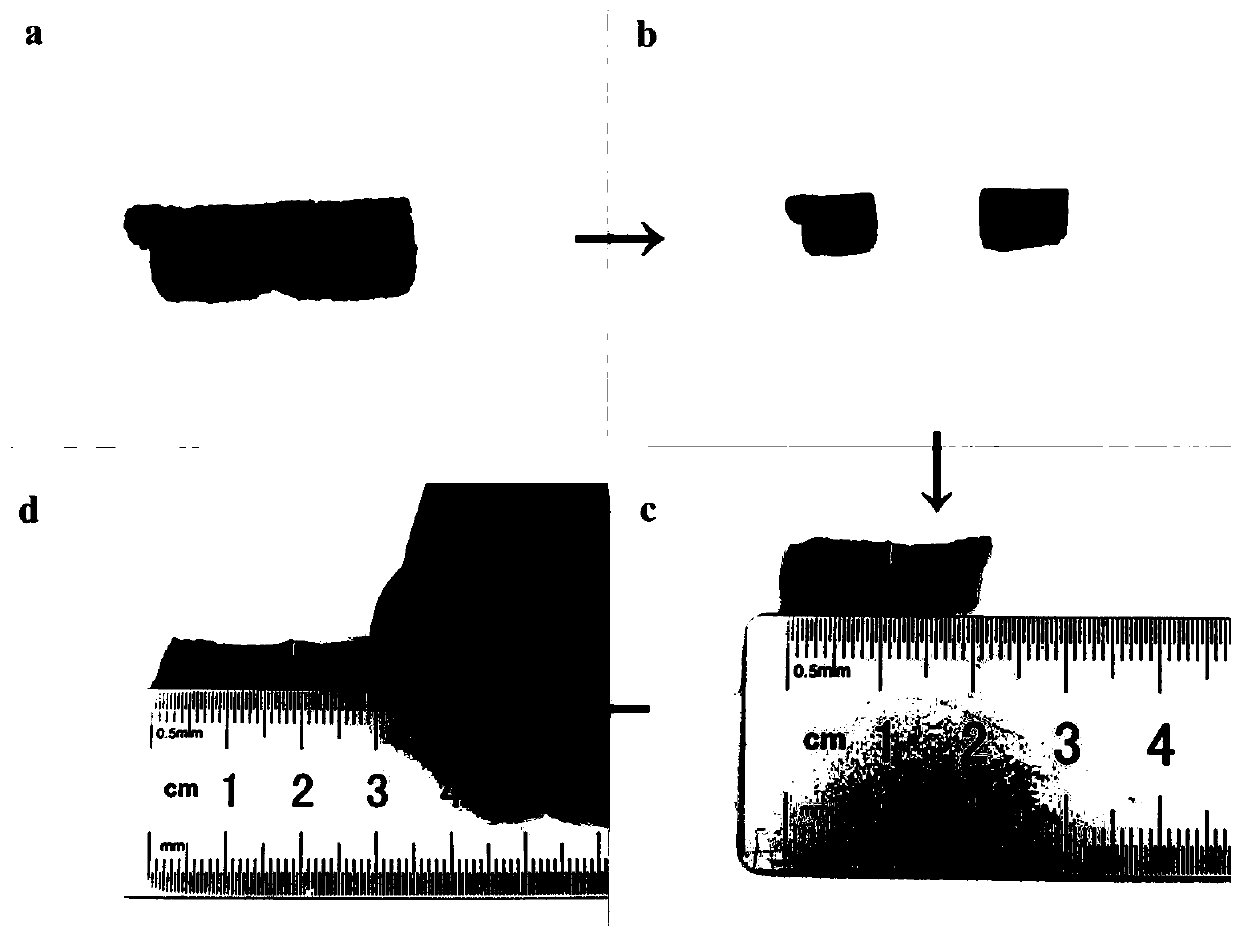

Image

Examples

Embodiment 1

[0032] Weigh 25 g of bromobutyl rubber and 1 g of butyl imidazole respectively. At a high temperature of 150°C, the mixture of components was cured in an internal mixer to obtain butyl imidazole-modified brominated butyl rubber INR. Weigh 1.6g of modified bromobutyl rubber INR and 30g of petroleum ether, and mix them for later use. After the mixture has stood at room temperature for more than 4 days, heat it in a water bath for 1 hour, and dissolve the INR with petroleum ether at 65°C to form a uniform mixture. solution to obtain a solution-like modified bromobutyl rubber INR. Weigh 0.16g of CB and 24g of deionized water, and stir with a high-speed mixer to form a uniform suspension. At a temperature of 65°C, slowly pour the CB suspension into the INR solution while stirring, and keep stirring for 20 min to obtain a CB@INR mixture. After removing the excess moisture layered out of the mixture material obtained in the previous step, pour it into a petri dish, place it in an o...

Embodiment 2

[0034] Weigh 26 g of bromobutyl rubber and 1 g of butyl imidazole respectively. At a high temperature of 150°C, the mixture of components was cured in an internal mixer to obtain butyl imidazole-modified brominated butyl rubber INR. Weigh 1.5g of modified bromobutyl rubber INR and 30g of petroleum ether, and mix them for later use. After the mixture is allowed to stand at room temperature for more than 4 days, heat it in a water bath for 1.5 hours, and dissolve the INR with petroleum ether at 65°C to form a uniform mixture. solution to obtain a solution-like modified bromobutyl rubber INR. Weigh 0.175g of CB and 28g of deionized water, and stir with a high-speed mixer to form a uniform suspension. At a temperature of 65°C, slowly pour the CB suspension into the INR solution while stirring, and keep stirring for 23 minutes to obtain a CB@INR mixture. After removing the excess moisture layered out of the mixture material obtained in the previous step, pour it into a petri dish...

Embodiment 3

[0036]Weigh 28 g of bromobutyl rubber and 1 g of butyl imidazole respectively. At a high temperature of 150°C, the mixture of components was cured in an internal mixer to obtain butyl imidazole-modified brominated butyl rubber INR. Weigh 1.4g of modified bromobutyl rubber INR and 30g of petroleum ether, and mix them for later use. After the mixture has stood at room temperature for more than 4 days, heat it in a water bath for 1 hour, and dissolve the INR with petroleum ether at 65°C to form a uniform mixture. solution to obtain a solution-like modified bromobutyl rubber INR. Weigh 0.135g of CB and 23g of deionized water, and stir with a high-speed mixer to form a uniform suspension. At a temperature of 65°C, slowly pour the CB suspension into the INR solution while stirring, and keep stirring for 25 minutes to obtain a CB@INR mixture. After removing the excess moisture layered out of the mixture material obtained in the previous step, pour it into a petri dish, place it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com