A kind of high-efficiency extraction system and extraction method of Baixiangru alkaloid

An extraction method and technology of alkaloids, applied in the direction of alkaloids, alkaloids, chemical instruments and methods, etc., can solve the problems of low fine fractionation level and inconvenient extraction of fine fractionation, achieve high level of fine fractionation, and facilitate small-dose experiments , Improve the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

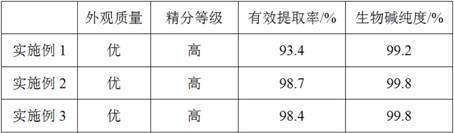

Embodiment 1

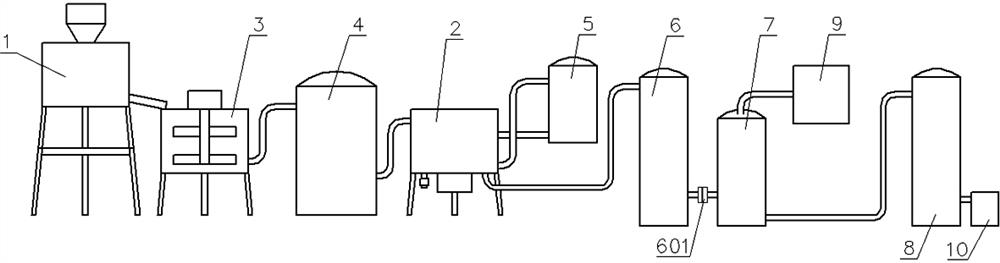

[0050] S100: Dried the cymbidium vetch in the sun, blowing it to remove dust, and then put it into the pulverizer 1 to pulverize it into powder, and sieved it through a 100-mesh sieve to obtain the syringa cymbidium powder.

[0051] S200: Take 10 parts of fenugreek powder and put it into reactor 3, inject 30 parts of clean water to mix, add hydrochloric acid to adjust the pH value to 3, stir slightly, let stand and soak at 40°C for 10 minutes, and then boil in the input The component 4 is uniformly heated and boiled for 2 hours under the condition of intermittent stirring, and the boiled mixed solution is passed into the centrifuge 2 for centrifugation to obtain the centrifuge liquid.

[0052] S300: Integrate the centrifugal supernatant into the concentration component 5, distill and concentrate at 80°C for 30 minutes, and then add 1 part of mixed enzyme (by mass ratio: 10 parts of cellulase) to the concentrated solution based on the mass parts of the fenugreek powder , 3 part...

Embodiment 2

[0058] S100: Dried the cypress vetch in the sun, blowing the ash off with the wind, and then put it into the pulverizer 1 to pulverize it into powder, and sieve it through a 110-mesh sieve to obtain the syringa cypress powder.

[0059] S200: Take 13 parts of fenugreek powder and put it into reactor 3, inject 60 parts of clean water to mix, add hydrochloric acid to adjust the pH value to 2, stir slightly and let it stand for 12 minutes at a water temperature of 50°C, and then boil it in the input Component 4 is evenly heated and boiled for 1.5 hours under the condition of intermittent stirring, and the boiled mixed solution is passed into centrifuge 2 for centrifugation to obtain a centrifuge supernatant.

[0060] S300: Integrate the centrifuge supernatant into the concentration component 5, distill and concentrate at 85°C for 40 minutes, then add 1.5 parts of mixed enzyme (according to mass ratio: 10 parts cellulase) , 5 parts of hemicellulase, 4 parts of pectinase) were subje...

Embodiment 3

[0066] S100: Dried the cypress vetch in the sun, blowing the ash off with the wind, and then putting it into the pulverizer 1 to pulverize it into powder, and sieving it through a 120-mesh sieve to obtain the sycamore vetch powder.

[0067] S200: Take 15 parts of fenugreek powder and put it into reactor 3, inject 90 parts of clean water to mix, add hydrochloric acid to adjust the pH value to 2.5, stir slightly, let stand and soak at 60°C for 15 minutes, and then boil in the input Component 4 is evenly heated and boiled for 1.5 hours under the condition of intermittent stirring, and the boiled mixed solution is passed into centrifuge 2 for centrifugation to obtain a centrifuge supernatant.

[0068] S300: Integrate the centrifugal supernatant into the concentration component 5, distill and concentrate at 90°C for 45 minutes, and then add 2 parts of mixed enzymes (by mass ratio: 10 parts of cellulase) to the concentrated solution based on the mass parts of the fenugreek powder , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com