Composite glass optical fiber for synchronously detecting optical signals, electrical signals and chemical signals and preparation method of composite glass optical fiber

A composite glass, synchronous detection technology, applied in glass manufacturing equipment, measuring devices, manufacturing tools, etc., can solve the problems of increasing the wound area of live animals and the difficulty of surgery, achieve synchronous and efficient transmission and recording, and small difference in refractive index distribution , the effect of uniform refractive index distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

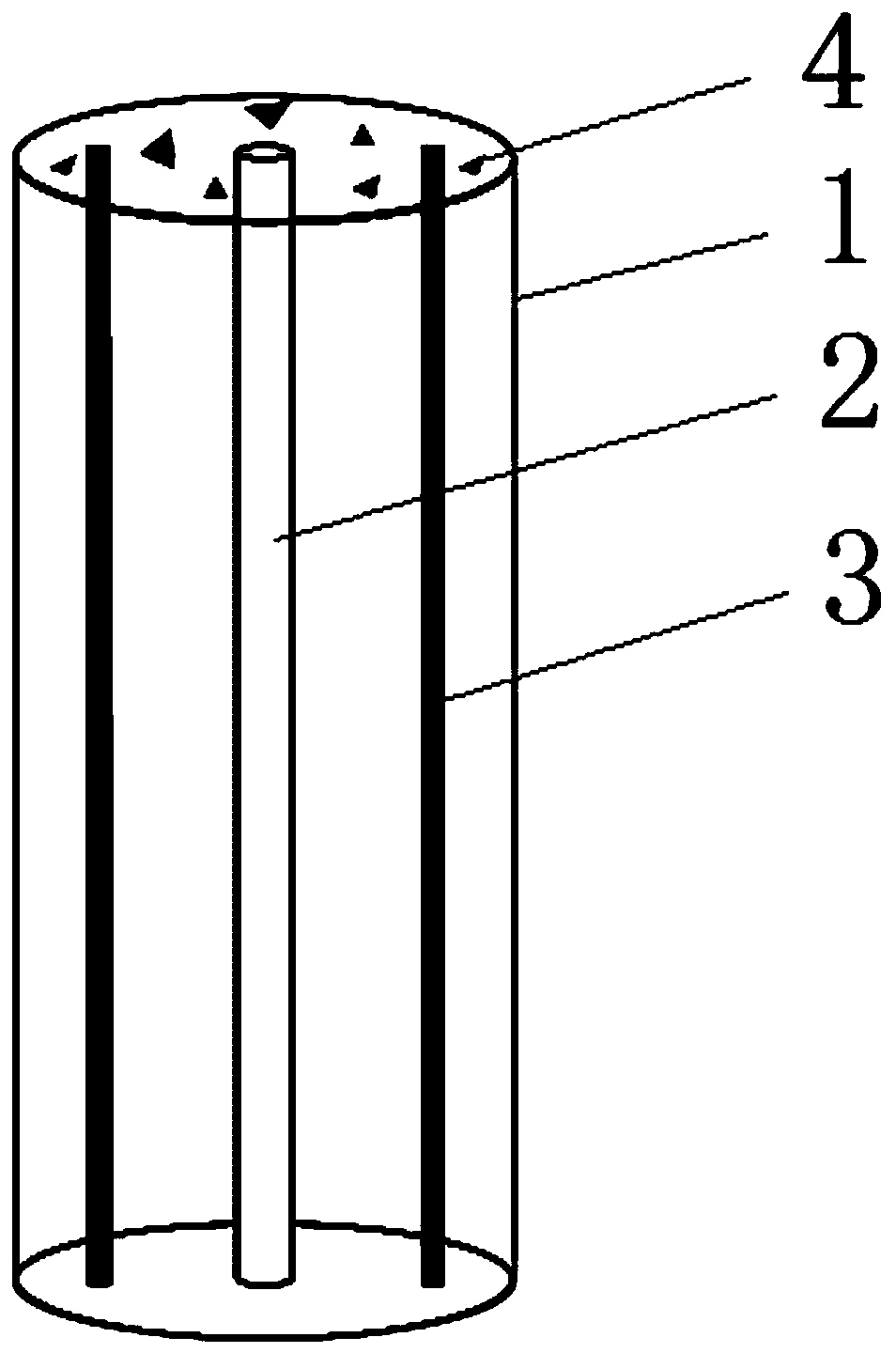

[0026] Such as figure 1 shown. The invention discloses a method for preparing a composite glass optical fiber for synchronous detection of photoelectrochemical signals, which can be prepared through the following process:

[0027] The optical fiber cladding 1 is prepared, that is, the glass material is prepared into a cylindrical preform rod; a first cylindrical cavity is prefabricated in the cylindrical preform rod, and a second cylindrical cavity is respectively prefabricated on both sides of the first cylindrical cavity to complete The optical fiber cladding 1 is prepared; the axis of the first cylindrical cavity is coaxial with the axis of the cylindrical preform; the axes of the second cylindrical cavity on both sides are parallel to the axis of the first cylindrical cavity; the glass core primary preform Preparation, that is, the glass core material is prepared into a cylindrical glass core 2 whose diameter is the same as that of the first cylindrical cavity in the opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com