Method for regenerating green energy by utilizing coking wastewater

A coking wastewater and green energy technology, applied in chemical instruments and methods, horticultural methods, energy wastewater treatment, etc., can solve problems such as time-consuming, environmental hazards, and slow physical methods, so as to avoid recombination and increase reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Sampling:

[0046] The coking waste water was taken from the local coking plant, and the magnetic magnesium aluminum hydrotalcite was synthesized by the co-precipitation method, and the required reagents (analytical grade) were purchased from the chemical reagent factory.

[0047] (2) Pretreatment of coking wastewater:

[0048] Take a certain amount of coking wastewater, irradiate it with electron beams for 13 minutes, and measure the irradiation at 0.5 kGy; after irradiation, let it stand still for 5 minutes; then add 0.5% (w / v) magnetic magnesium aluminum to it under the condition of avoiding light Hydrotalcite, fully stirred for 10 minutes, and then filtered to collect the coking wastewater liquid.

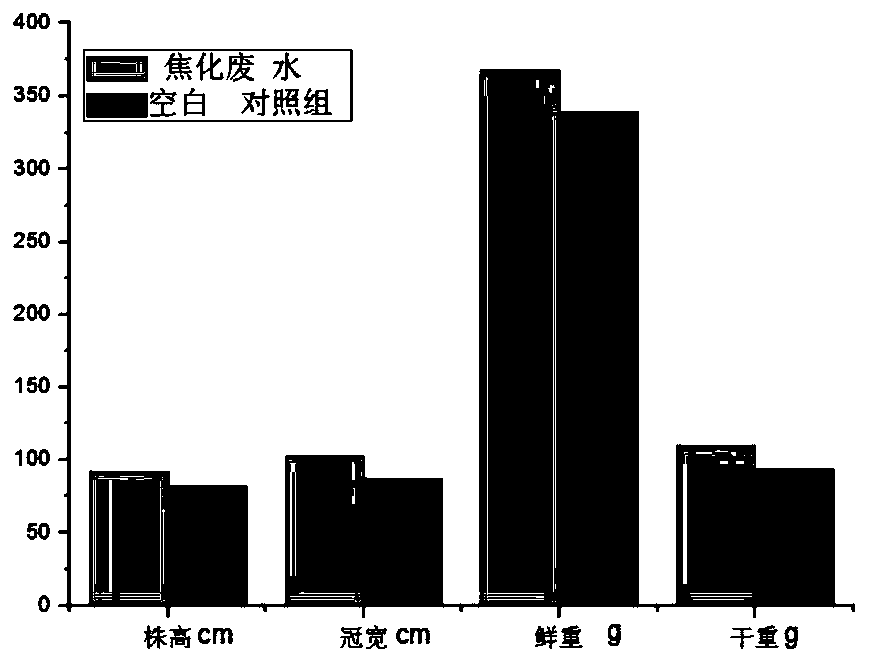

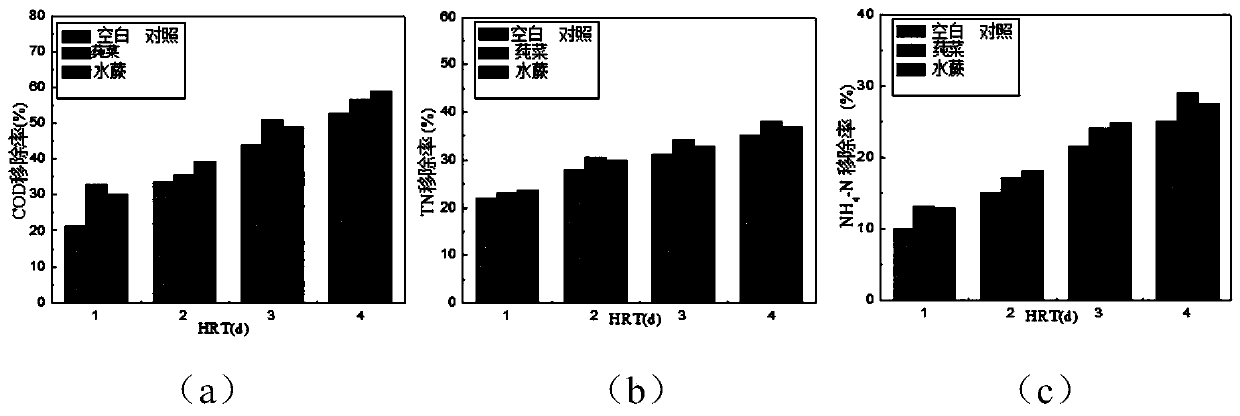

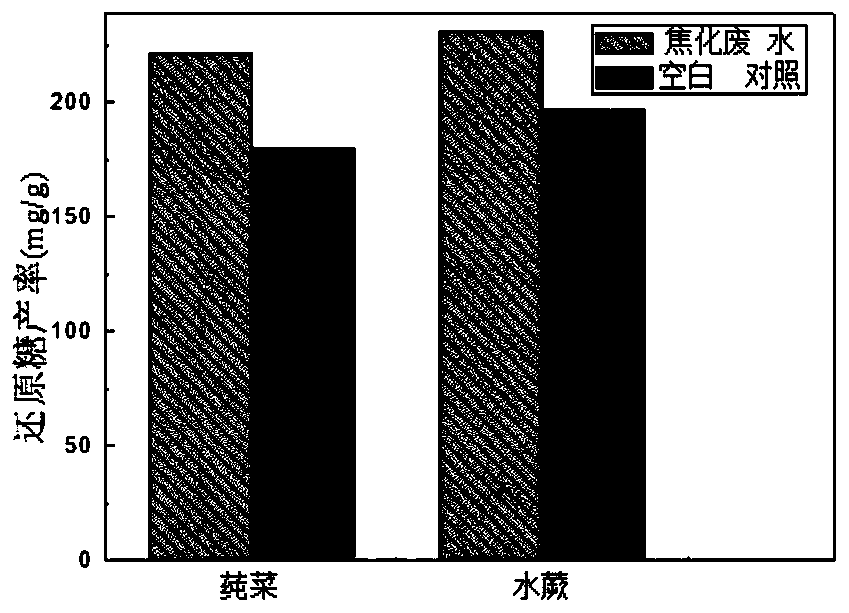

[0049] (3) Plant planting:

[0050] Get a certain amount of pretreated coking waste water, dilute to 15% (v / v) concentration with deionized water; diameter 1mm), the selected disease-free water shield seedlings with the same height and water fern seedlings with th...

Embodiment 2

[0058] (1) Sampling:

[0059] The sampling of coking wastewater and required chemical reagents is the same as in Example 1.

[0060] (2) Pretreatment of coking wastewater:

[0061] Take a certain amount of coking wastewater, irradiate it with electron beams for 14 minutes, and measure the radiation at 0.6 kGy; after irradiation, let it stand still for 6 minutes; then add 1% (w / v) magnetic magnesium aluminum to it under the condition of avoiding light Hydrotalcite, fully stirred for 11 minutes, and then filtered to collect the coking wastewater liquid.

[0062] (3) Plant planting:

[0063] Get a certain amount of pretreated coking waste water, dilute to 20% (v / v) concentration with deionized water; diameter 2mm), the selected disease-free water shield seedlings with the same height and water fern seedlings with the same height were planted in clay pots, and each pot planted a water shield seedling and a water fern seedling, and kept a distance of 18 cm between water shield a...

Embodiment 3

[0071] (1) Sampling:

[0072] The sampling of coking wastewater and required chemical reagents is the same as in Example 1.

[0073] (2) Pretreatment of coking wastewater:

[0074] Take a certain amount of coking wastewater, irradiate it with electron beams for 15 minutes, and measure 0.7 kGy of radiation; after irradiation, let it stand still for 7 minutes; then add 1.5% (w / v) magnetic magnesium aluminum to it under the condition of avoiding light Hydrotalcite, fully stirred for 12 minutes, and then filtered to collect the coking wastewater liquid.

[0075] (3) Plant planting:

[0076] Get a certain amount of pretreated coking waste water, dilute to 22% (v / v) concentration with deionized water; diameter 13mm), the selected disease-free water shield seedlings with the same height and water fern seedlings with the same height are planted in pottery pots, one water shield seedling and one water fern seedling are planted in each pot, and the distance between water shield and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com