Biochar/zeolite composite adsorbent material and preparation method thereof

A composite adsorption and biochar technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as difficult to achieve purification effect, complicated treatment process, etc., to achieve environmental protection and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

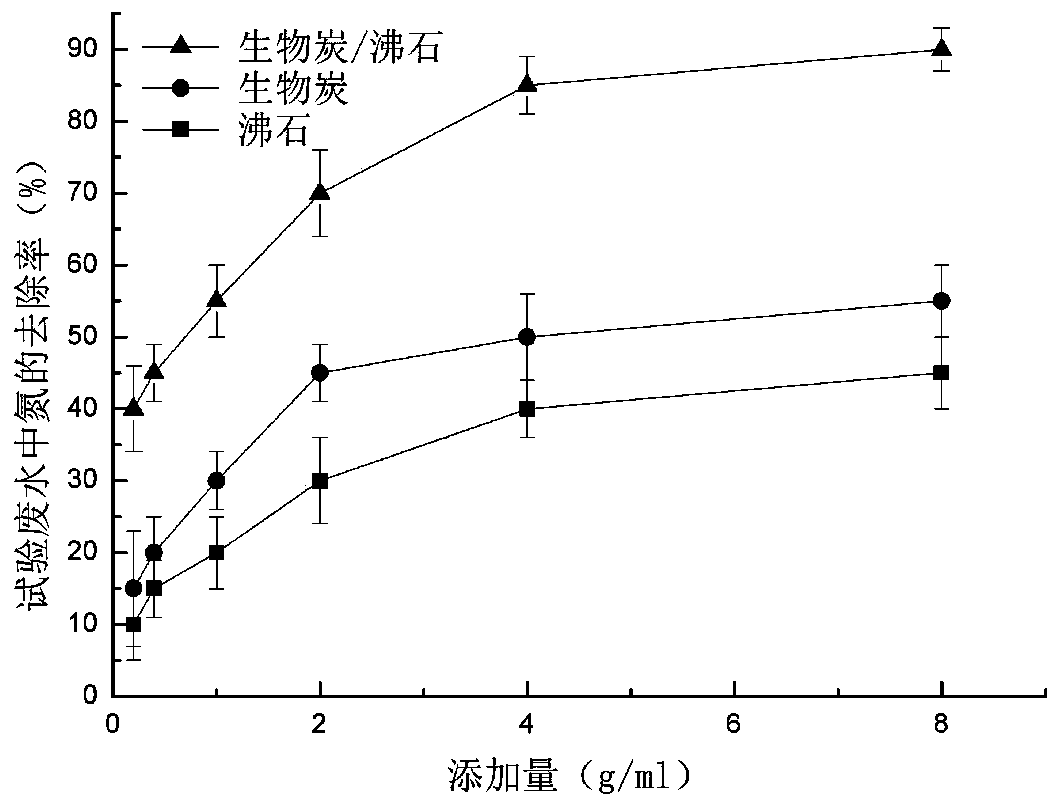

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing biochar / zeolite composite adsorbent material from biomass, comprising the following steps:

[0028] 1) The biomass raw material is dried and dehydrated to less than 1%: After the solid biomass is preliminarily cleaned to remove impurities such as soil, the biomass is fully dehydrated in a drying oven or under natural ventilation conditions until the moisture content does not exceed 1%.

[0029] 2) The dried raw materials are crushed to particles below 1mm: the dried raw materials are crushed by a pulverizer and passed through a 1mm sieve to make them into particles with a diameter not greater than 1mm;

[0030] 3) Thermal cracking treatment: pyrolyze the obtained biomass particles in a microwave pyrolysis furnace under protective gas such as nitrogen, helium or oxygen-limited conditions, using a temperature of 400°C and a holding time of 1-2 hours to obtain biochar Material;

[0031] 4) Alkali zeolite treatment: add the o...

Embodiment 2

[0035] This embodiment provides a method for preparing biochar / zeolite composite adsorbent material from biomass, comprising the following steps:

[0036] 1) The biomass raw material is dried and dehydrated to less than 1%: After the solid biomass is preliminarily cleaned to remove impurities such as soil, the biomass is fully dehydrated in a drying oven or under natural ventilation conditions until the moisture content does not exceed 1%.

[0037] 2) The dried raw materials are crushed to particles below 1mm: the dried raw materials are crushed by a pulverizer and passed through a 1mm sieve to make them into particles with a diameter not greater than 1mm;

[0038] 3) Thermal cracking treatment: pyrolyze the obtained biomass particles in a microwave pyrolysis furnace under nitrogen, helium and other protective gases or oxygen-limited conditions, using a temperature of 600°C and a holding time of 1-2 hours to obtain biochar Material;

[0039] 4) Alkaline zeolite treatment: add...

Embodiment 3

[0042] This embodiment provides a method for preparing biochar / zeolite composite adsorbent material from biomass, comprising the following steps:

[0043] 1) The biomass raw material is dried and dehydrated to less than 1%: After the solid biomass is preliminarily cleaned to remove impurities such as soil, the biomass is fully dehydrated in a drying oven or under natural ventilation conditions until the moisture content does not exceed 1%.

[0044] 2) The dried raw materials are crushed to particles below 1mm: the dried raw materials are crushed by a pulverizer and passed through a 1mm sieve to make them into particles with a diameter not greater than 1mm;

[0045] 3) Thermal cracking treatment: pyrolyze the obtained biomass particles in a microwave pyrolysis furnace under nitrogen, helium and other protective gases or oxygen-limited conditions, using a temperature of 700°C and a holding time of 1-2 hours to obtain biochar Material;

[0046] 4) Alkaline zeolite treatment: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com