Flapping pore-dredging device for biomass granulator

A technology of biomass granulation and porosity, which is applied in the direction of mold extrusion granulation, etc., can solve the problems of cumbersome operation process and difficulty in unifying the cleaning effect of various parts, and achieve low operation difficulty, effective and reliable cleaning effect, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

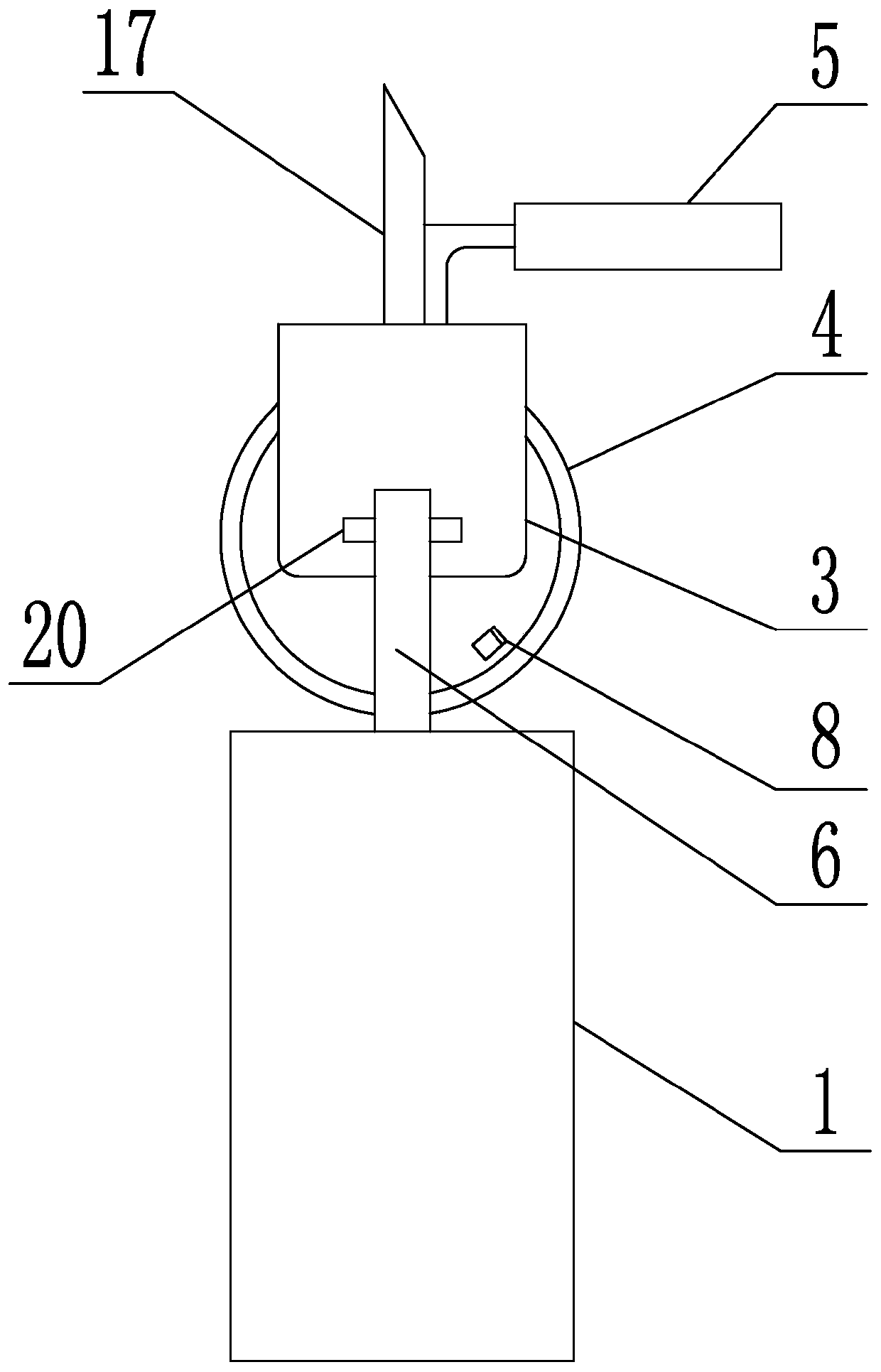

[0029] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, this specific embodiment adopts the following technical solutions. This embodiment includes an outer wall arc plate 1, an inner wall arc plate 2, a support frame 3, a roller 4, a grip portion 5, an outer connecting rod 6 and an inner connecting rod 7, The gripping part 5 is arranged on the top of the support frame 3, the roller 4 is arranged in the support frame 3, and the outer walls of both sides of the roller 4 are respectively provided with several first pads 8 and several second pads 9, The outer side wall arc plate 1 is hinged on one side of the support frame 3 through the outer connecting rod 6, and the inner side wall of the outer connecting rod 6 is provided with a first bump 10 matched with the first pad 8, and the inner side wall The arc plate 2 is hinged on the other side of the support frame 3 through the inner connecting rod 7, the inne...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is a further limitation of Embodiment 1. A plurality of first cylinders 12 are arranged on the side wall of the outer wall arc plate 1 facing the roller 4, and the height of the plurality of first cylinders 12 is from The two ends of the outer wall arc plate 1 and the middle part of the outer wall arc plate 1 decrease successively. Such arrangement is in order to match the shape of ring die 18 better.

[0033] Further, one cleaning method of the first cylinder 12 is that it is not aligned with the ring die hole 19, and when the outer wall arc plate 1 hits the ring die 18 directly, the effect of clicking and hitting the outer wall of the ring die 18 is realized, and multiple first The cylinder 12 realizes the process of multi-point knocking on the ring die 18 from the outside to enhance the cleaning strength.

[0034] Further, another cleaning method of the first cylinder 12 is that it just passes through the ring die hole 19, and the end o...

specific Embodiment approach 3

[0038] Specific Embodiment 3: This embodiment is a further limitation of Specific Embodiment 1 or 2. A plurality of second cylinders 13 are arranged on the side wall of the inner wall arc plate 2 facing the roller 4, and the plurality of second cylinders 13 The height decreases successively from the two ends of the inner wall arc plate 2 to the middle of the inner wall arc plate 2 .

[0039] Further, a cleaning method of the second cylinder 13 is that it is not aligned with the ring die hole 19, and when the outer wall arc plate 1 hits the ring die 18 directly, the effect of clicking and hitting the outer wall of the ring die 18 is realized, and multiple second The cylinder 13 realizes the process of multi-point knocking on the ring die 18 from the inside to enhance the cleaning strength.

[0040]Further, another cleaning method of the second cylinder 13 is that the end of the second cylinder 13 toward the ring die 18 is a round end, and its outer diameter is smaller than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com