System and technology for treating unstable large-volume VOCs waste gas

A technology of treatment system and treatment process, which is applied in the field of treatment system of VOCs waste gas with unstable large volume, can solve the problems of waste gas treatment, failure to meet the requirements of new standards, and low adsorption capacity of rotor adsorbent, so as to reduce volatility and stabilize The effect of uniform purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

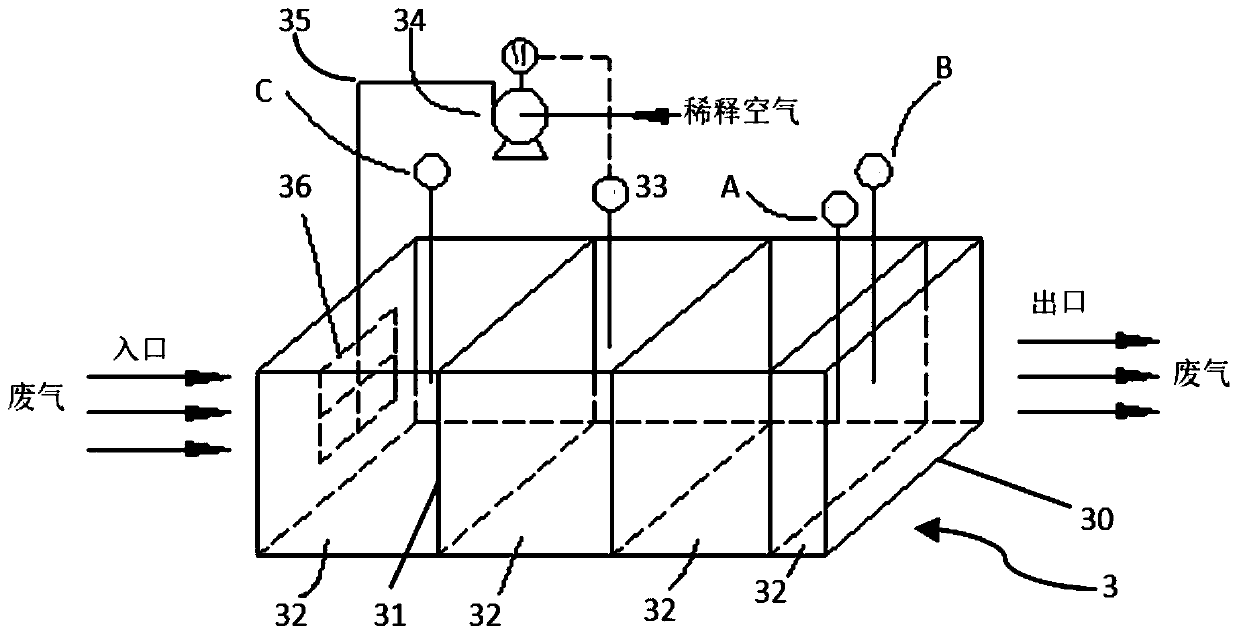

[0064] like figure 1 As shown, the present embodiment is a treatment system for unstable atmospheric volume VOCs waste gas, including:

[0065] Pretreatment equipment 1 is used to pretreat the exhaust gas, filter the dust in the exhaust gas, and purify the non-VOCs substances in the exhaust gas at the same time;

[0066] The outlet of the pretreatment device 1 is connected to an adsorption concentration device 2 for performing adsorption and concentration treatment on the pretreated waste gas;

[0067] The outlet of the adsorption concentration device 2 is communicated with the high-energy level photooxidation device 4 through the homogenization connection device 3, and the outlet end of the high-energy level photooxidation device 4 is also connected to the discharge pipeline P through the washing device 5;

[0068] Wherein, the adsorption and concentration device 2 is provided with a hot purification gas inlet and a desorption gas outlet, and the desorption gas outlet is con...

Embodiment 2

[0084] This embodiment is a treatment method for unstable atmospheric VOCs waste gas, which is characterized in that the following treatment is carried out:

[0085] S1. Introduce the exhaust gas into the adsorption pretreatment equipment for pretreatment, mainly to filter the dust in the exhaust gas, and at the same time purify the non-VOCs substances in the exhaust gas; the average concentration of VOCs in the exhaust gas ranges from 0 to 1000mg / m 3 , the short-term maximum concentration is controlled at 5000-22000mg / m 3 , the air volume is controlled at 5000m 3 / h above;

[0086] S2. Carry out adsorption and concentration treatment on the pretreated gas through adsorption and concentration equipment;

[0087] S3. The exhaust gas after adsorption and concentration enters the homogenization connection equipment for homogenization treatment, and then enters the high-energy level photooxidation equipment to further purify the remaining VOCs exhaust gas. After the purified gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com