Multi-field synergistic microwave liquid-phase constant-temperature desorption integrated system

An integrated system and field synergy technology, applied in the chemical/physical/physicochemical process of applied energy, evaporator adjustment/control, evaporator accessories, etc., can solve the problem of microwave liquid phase constant temperature desorption process system with few methods No public publications, unsatisfactory desorption performance, etc. have been found, and the effect of improving gas-liquid mass transfer capacity has been achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

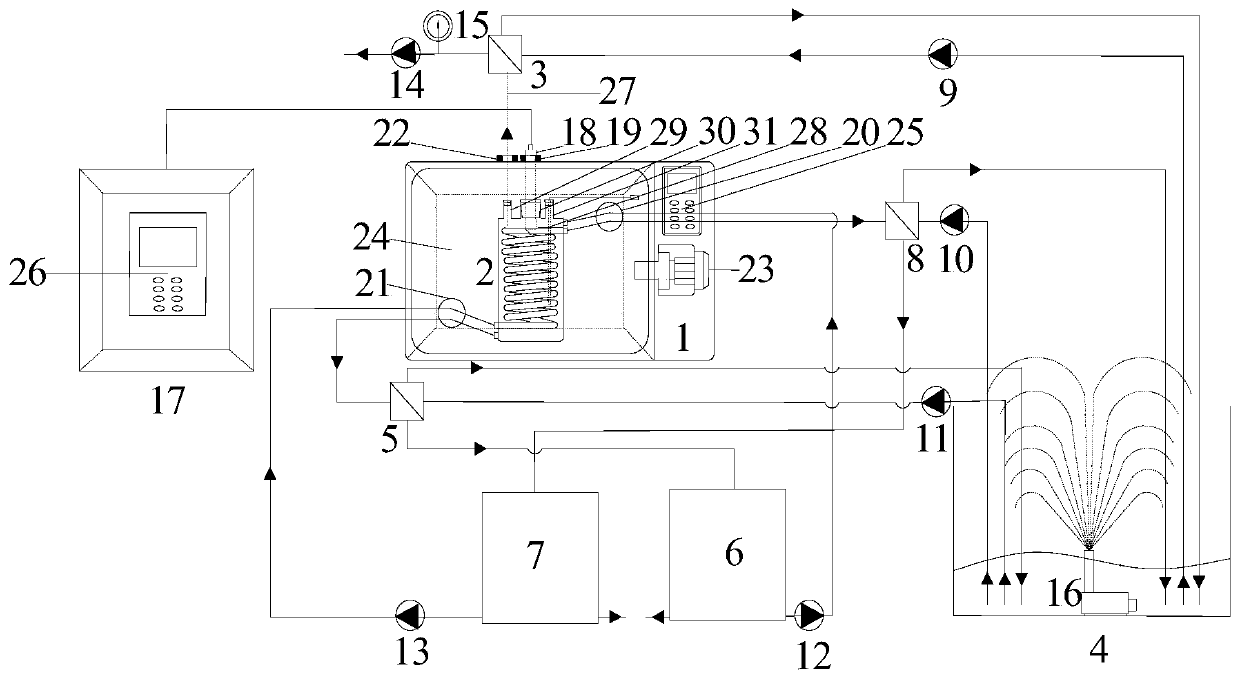

[0039] A multi-field synergistic microwave liquid phase constant temperature desorption integrated system, including a desorption system and a heat exchange system, the desorption system includes a microwave desorption device 1, an ultrasonic generator 17 and an ultrasonic transducer 18, and the microwave desorption device 1 is provided with a desorption reactor 2. The heat exchange system includes a condenser 3, a first coolant injection pool 4, a first heat exchanger 5, a desorption liquid storage tank 6, a second coolant storage tank 7, a second heat exchanger 8, and a first liquid pump 9. The second liquid pump 10, the third liquid pump 11, the fourth liquid pump 12, the fifth liquid pump 13, the vacuum pump 14 and the liquid jet pump 16;

[0040] The first exhaust port 29 provided on the shell of the desorption reactor 2 communicates with the tube-side inlet of the condenser 3 through the exhaust pipe 27, and the tube-side outlet of the condenser 3 is communicated with a v...

Embodiment 2

[0055]A multi-field synergistic microwave liquid-phase internal cooling static constant temperature desorption process: the circulation device system of the desorption liquid storage tank 6 and the first heat exchanger 5 is in a cut-off state, and the desorption liquid is in a static state and all placed in the desorption reactor 2 Between the shell and the inner tube, turn on the desorption device 1, the first liquid pump 9, and the vacuum pump 14 in sequence, and the desorbed gas-vapor mixed product is pumped out by the vacuum pump 14, and the vacuum pressure gauge 15 monitors the gap between the shell and the inner tube of the desorption reactor 2 The cooling water in the first cooling liquid injection pool 4 is sent into the condenser 3 by the first liquid pump 9, and exchanges heat with the gas-steam mixed product at the exhaust outlet of the desorption reactor 2 to realize the condensation of water vapor Backflow, when the temperature of the desorption liquid rises to the...

Embodiment 3

[0057] A multi-field synergistic microwave liquid-phase internal cooling dynamic constant temperature desorption process: the cooling water circulation system on the shell side of the first heat exchanger 5 is in a cut-off state, the desorption liquid is in a flowing state, and part of it is placed between the shell of the desorption reactor 2 and the Between the inner tubes, a part is placed in the desorption liquid storage tank 6, and the desorption device 1, the first liquid pump 9, and the vacuum pump 14 are turned on in sequence, and the desorbed gas-vapor mixed product is extracted by the vacuum pump 14, and the vacuum pressure gauge 15 monitors the desorption reaction The pressure between the shell and the inner pipe of the device 2, the cooling water in the first cooling liquid injection pool 4 is sent into the condenser 3 by the first liquid pump 9, and the gas-vapor mixed product at the exhaust outlet of the desorption reactor 2 is carried out. Heat exchange and reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com