Frozen meat stringing machine for hotel kitchens

A technology of stringer and frozen meat, which is applied in the field of frozen meat stringer for hotel kitchens, can solve the problems of high labor intensity, unsanitary, hidden safety hazards, etc., and achieve the effects of high degree of automation, good use effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

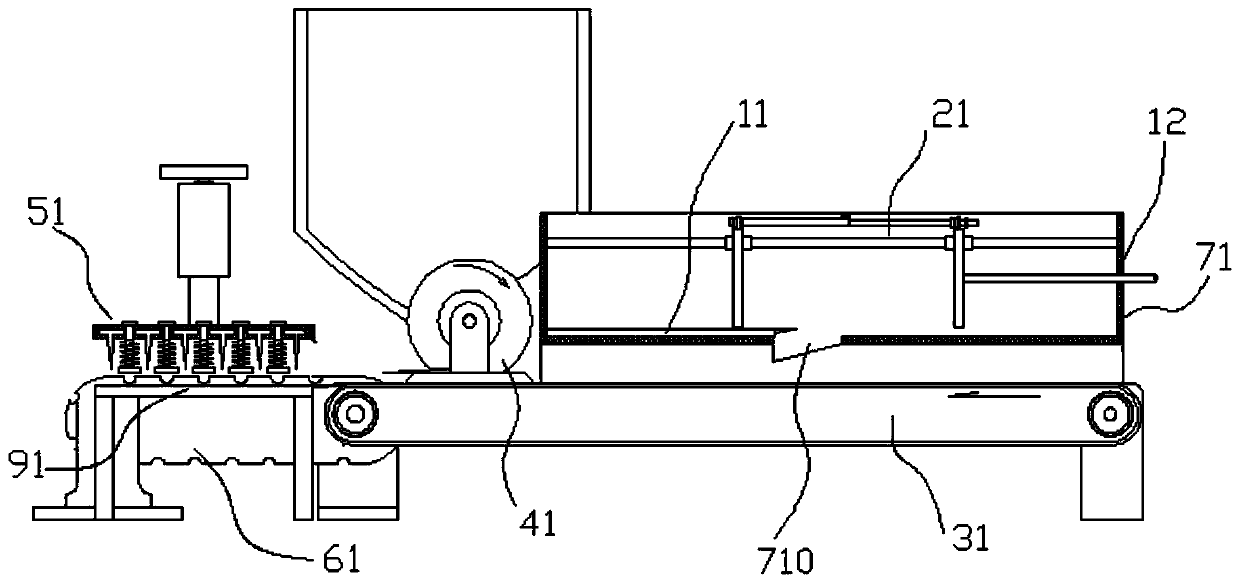

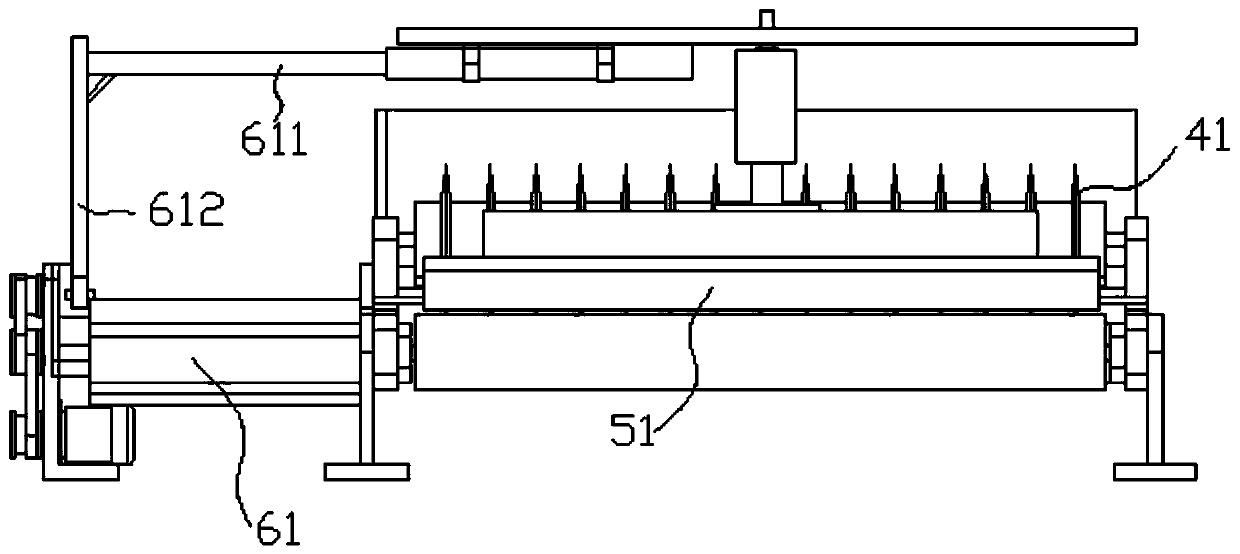

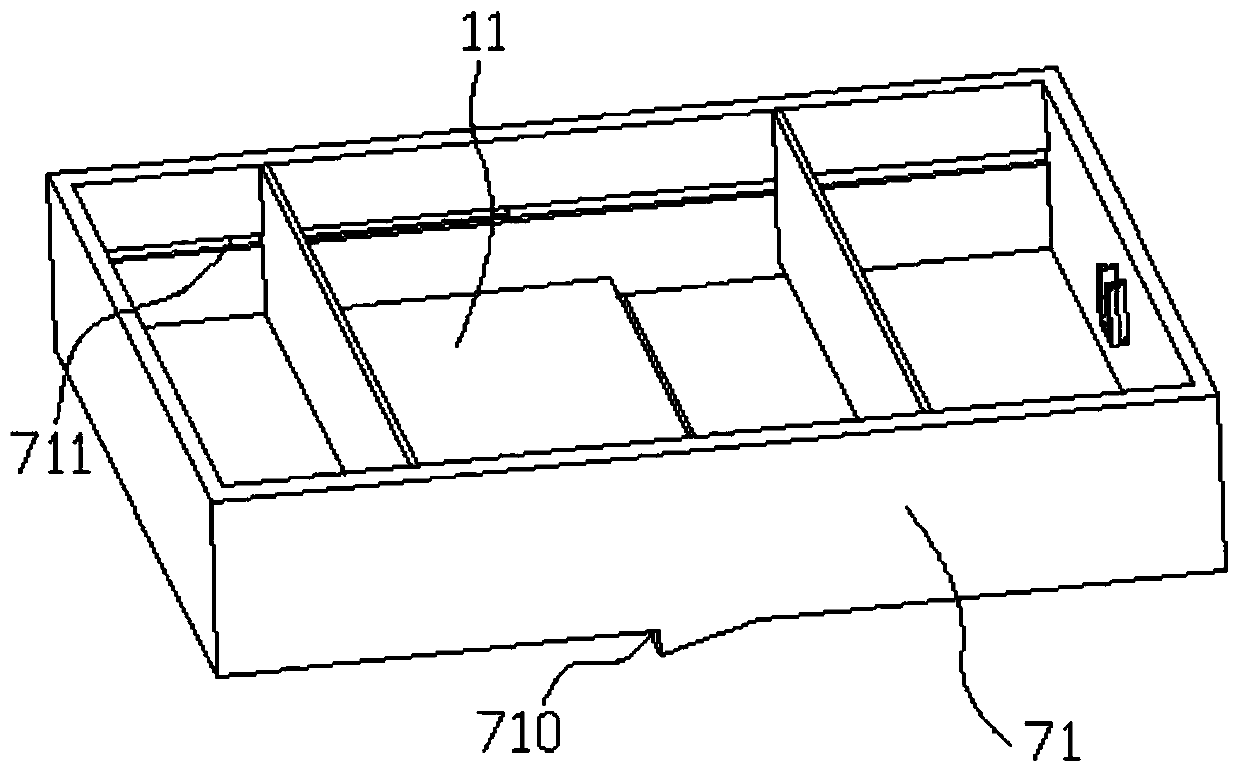

[0028] Such as figure 1 with figure 2 , the present invention is a frozen meat skewering machine for hotel kitchens. The skewering machine of the present invention is specially used to cut the frozen meat frozen into rectangular blocks into skewers, and make the skewered meats just cut into meat slices. string. The threading machine of the present invention comprises a chipping knife 11 , a reciprocating unit 21 , a conveyor belt 31 , a strip cutting knife 41 , a cutting knife 51 and a signing mechanism 61 . The chipping knife 11, the strip cutting tool 41 and the cutting tool 51 are all arranged on the top of the conveyor belt 31 and arranged side by side along the conveying direction of the conveyor belt 31 from left to right. The reciprocating unit 21 is arranged on the top of the chipping knife 11. 61 is arranged on the rear side of the cutting tool 51 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com