High-power and high-roundness industrial laser

A laser, high-power technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of cumbersome operation, Brewster surface damage, short working life, etc., to improve the roundness of the spot and achieve stability. performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

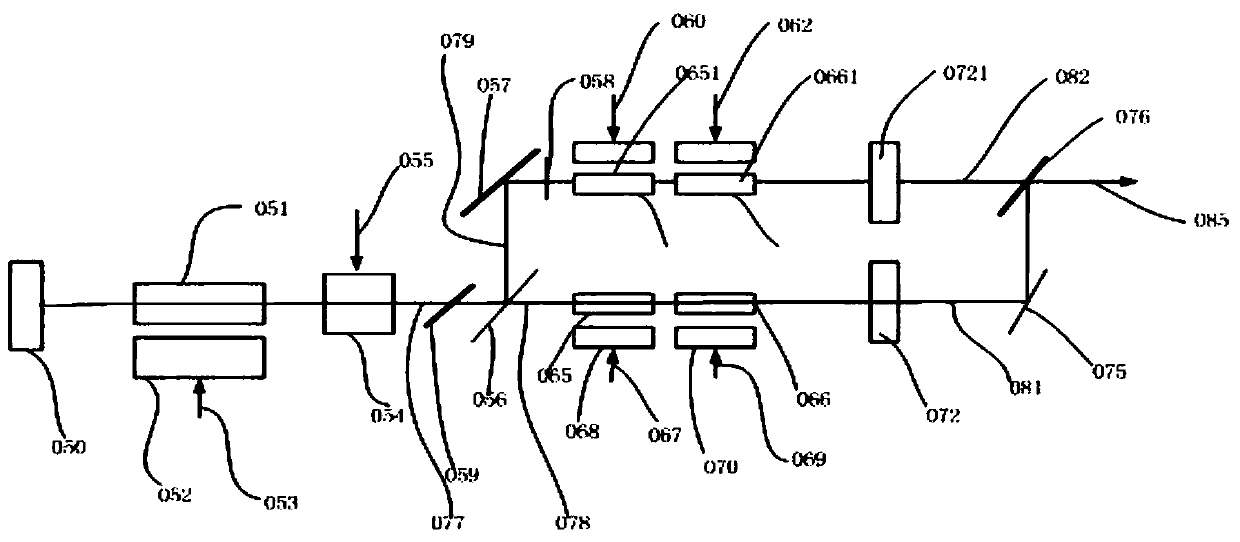

[0019] Depend on figure 1 As shown, 050 is the rear cavity mirror of the laser cavity, which is a high reflection mirror for the laser fundamental wave, 051 is the laser working medium, 052 is the pumping laser diode, 053 is the driving current of the pumping laser diode 052, and 054 is the acousto-optic Q switch , 055 is the radio frequency drive of the acousto-optic Q switch 054, and 059 is the first beam splitter. The laser fundamental wave beam 077 is divided into two beams by the first beam splitter 059, one beam 078 passes through the first double frequency crystal 065 and the first triple frequency crystal 066, and part of it is converted into triple frequency ultraviolet laser through the first The resonant cavity mirror 072 outputs, and the output first ultraviolet laser beam is 081; another beam of laser fundamental wave beam 079 is reflected by the second beam splitter 056 to the first turning mirror 057 and then reflected, and the laser fundamental wave 1 / 2 wave p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com