A test system and method for atomization spraying effect of natural gas drag reducer

An effect test and drag reducer technology, which is applied in the field of natural gas drag reducer atomization spraying effect test system, can solve the problem of inability to accurately judge the effect of drag reducer atomization spraying, the inability to obtain the pipeline flow rate environment, and the inability to simulate the diameter of natural gas pipelines etc. to achieve reliable test results, simple test methods, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

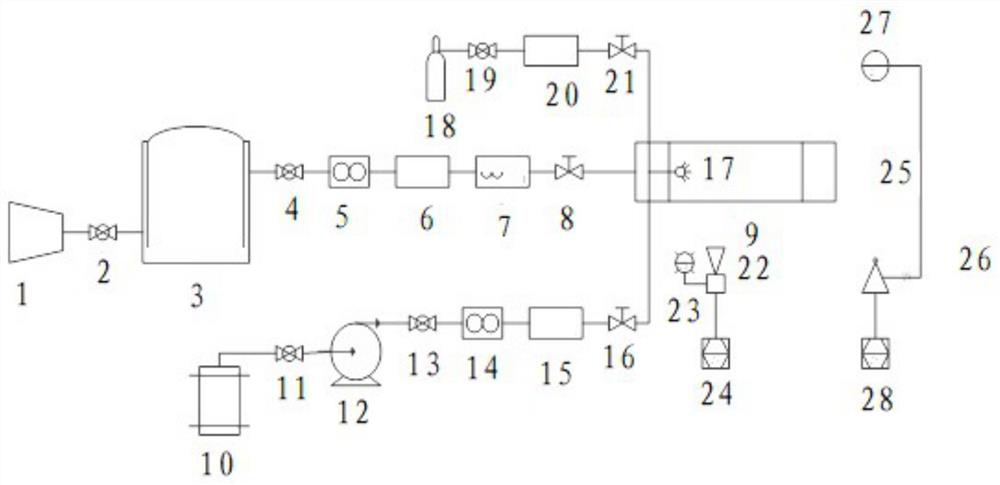

[0037] This embodiment provides a natural gas drag reducer atomization spraying effect test system, including: simulated pipeline system, atomization filling system, high-speed camera system and spray particle size measurement system;

[0038] Wherein, the atomization filling system is used for filling the drag reducer into the simulated pipeline system;

[0039] The high-speed camera system is used to collect atomized spray images;

[0040] The spray particle size measurement system is used to measure the particle size of the atomized particles of the drag reducer and its change with time, and automatically generate a "particle size-time" curve.

[0041] Further, the simulated piping system includes sequentially connected compressors, buffer tanks, gas flow meters, pressure sensors, temperature sensors, and transparent test pipe sections; in order to obtain better test results, ball valves, Valves such as precision regulating valves; for example, there are ball valves betwee...

Embodiment 2

[0049] This embodiment specifically illustrates the use of the test system to evaluate the atomized spraying effect of the drag reducer:

[0050] A natural gas pipeline is 50.54km long, with a design pressure of 4.0MPa, a pipe diameter of φ273, and a design capacity of 100 million standard cubic meters per year.

[0051] Due to seasonal peak shaving requirements, the pipeline adopts the method of atomizing and filling natural gas pipeline drag reducer to increase the transmission.

[0052] The specific process of evaluating the effect of atomized spraying of natural gas drag reducer is as follows:

[0053] 1. In order to be as close to the actual production as possible, before carrying out the evaluation of the atomization effect, the operating parameters of the simulated gas transmission pipeline must be determined, and the gas flow rate in the simulated pipeline is required to be similar to the flow rate in the actual pipeline.

[0054] According to the actual pipeline info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com