Single-crystal nickel-based high-temperature alloy cold deformation restoring method

A nickel-based superalloy, cold deformation technology, applied in the field of metal heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

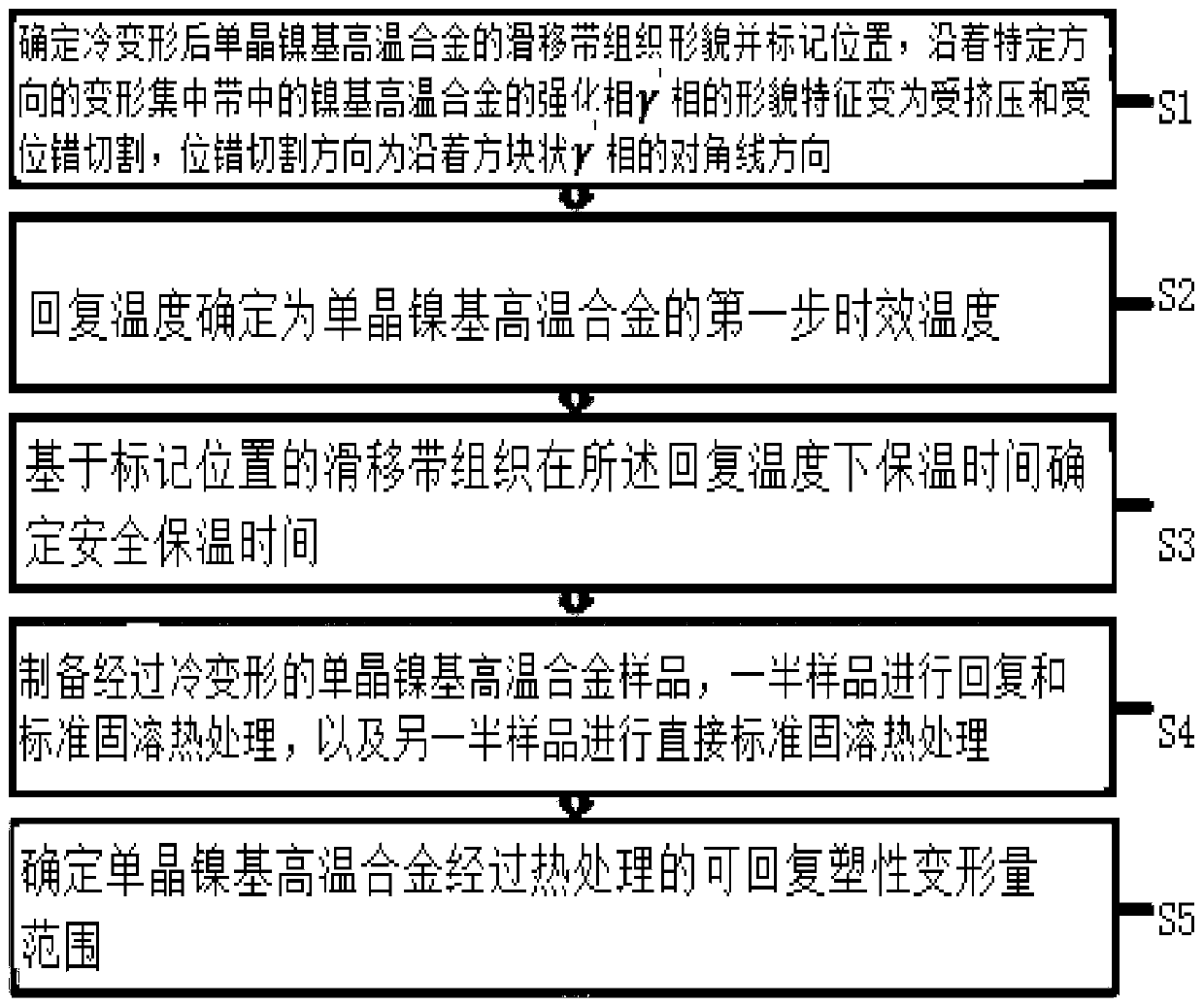

[0043] Step 1: Determine the slip zone morphology of the single crystal nickel-based superalloy after cold deformation and mark the position;

[0044] Step 2: The recovery temperature is determined as the first aging temperature of the nickel-based superalloy, that is, 1080°C.

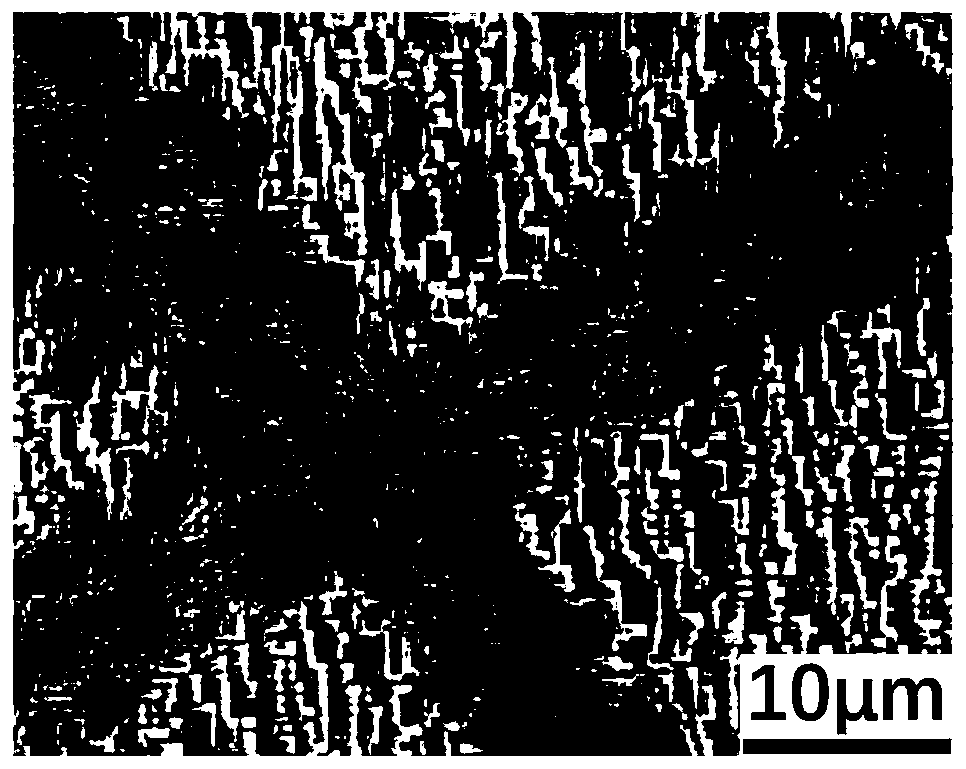

[0045] Step 3: Study the evolution law of the microstructure of the slip zone at the mark of the cold deformation sample at the recovery temperature for different periods of time. When it does not grow significantly, determine the safe holding time of the recovery process as 330 minutes, and the tissue after the growth is stopped See status image 3 .

[0046] Step 4: Prepare a nickel-based superalloy compression sample with an aspect ratio of 2:1. The average value of the sample height is 9.91 mm after multiple measurements; the deformation is introduced from 1% to 5.5 mm by the normal temperature compression mode of the universal testing machine. %A total of 10 samples, the plastic deformation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com