Method for preparing oxygen carrier of fuel coal chemical-looping combustion by using equal volume impregnation process

A technology of chemical chain combustion and equal volume impregnation, which is applied in the direction of fuel, fuel additives, petroleum industry, etc., can solve the problems of insufficient utilization of red mud, land occupation, and environmental pollution caused by strong alkalinity, so as to achieve resource efficiency Utilization, good reactivity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

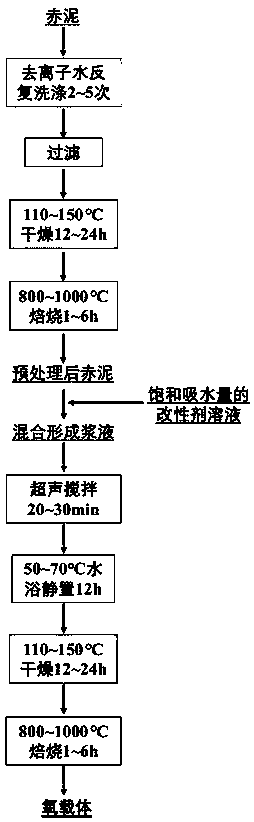

[0022] Such as figure 1 As shown, the method for preparing coal-fired chemical looping combustion oxygen carrier by equal-volume impregnation method comprises the following steps:

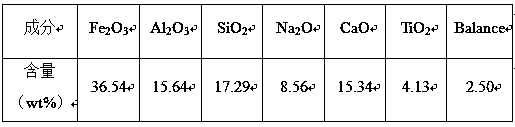

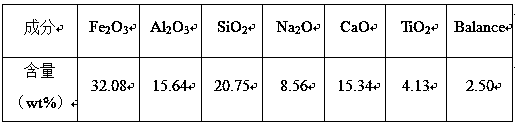

[0023] Step 1. Wash the red mud repeatedly until the pH is 7, dry it at 120°C for 12 hours, and then roast it at 900°C for 4 hours to make fine particles, internally porous, and specific surface area Large materials are ground into red mud powder after roasting, and a small part of the red mud powder is taken to measure the saturated water absorption of the red mud; the specific process of measuring the saturated water absorption of the red mud is: add excess deionized water to the red mud powder Water to obtain a slurry, the slurry was stirred ultrasonically (ultrasonic frequency: 53kHz) for 25 minutes and then placed in a constant temperature water bath at 60°C for 12 hours; the supernatant in the placed slurry was poured out and the volume was measured, and the volume of excess deionized water w...

Embodiment 2

[0030] Such as figure 1 As shown, the method for preparing coal-fired chemical looping combustion oxygen carrier by equal-volume impregnation method comprises the following steps:

[0031] Step 1. Wash the red mud repeatedly until the pH is 7, dry it at 110°C for 24 hours, and then roast it at 800°C for 2 hours to make fine particles, internally porous, and specific surface area Large materials are ground into red mud powder after roasting, and a small part of the red mud powder is taken to measure the saturated water absorption of the red mud; the specific process of measuring the saturated water absorption of the red mud is: add excess deionized water to the red mud powder Water to obtain a slurry, the slurry was stirred ultrasonically (ultrasonic frequency: 53kHz) for 20 minutes and placed in a constant temperature water bath at 60°C for 12 hours; the supernatant in the placed slurry was poured out and the volume was measured, and the volume of excess deionized water was su...

Embodiment 3

[0038] Such as figure 1 As shown, the method for preparing coal-fired chemical looping combustion oxygen carrier by equal-volume impregnation method comprises the following steps:

[0039]Step 1. Wash the red mud repeatedly until the pH is 7, dry it at 130°C for 12 hours, and then roast it at 1000°C for 2 hours to make fine particles, internally porous, and specific surface area Large materials are ground into red mud powder after roasting, and a small part of the red mud powder is taken to measure the saturated water absorption of the red mud; the specific process of measuring the saturated water absorption of the red mud is: add excess deionized water to the red mud powder Water to obtain a slurry, the slurry was stirred ultrasonically (ultrasonic frequency: 53kHz) for 30 minutes and then placed in a constant temperature water bath at 70°C for 12 hours; the supernatant in the placed slurry was poured out and the volume was measured, and the volume of excess deionized water w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com