Substrate for preparing polyurethane screen with high temperature resistance and moisture and heat resistance

A polyurethane, moisture-resistant technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of poor mechanical properties, easy hydrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

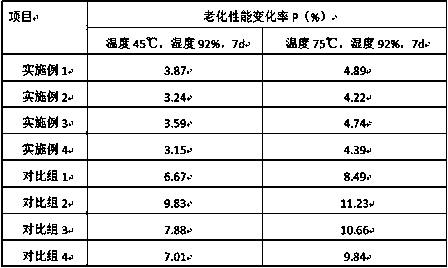

Examples

Embodiment 1

[0021] A substrate for preparing high-temperature-resistant and heat-and-humidity-resistant polyurethane mesh, comprising the following steps:

[0022] (1) Preparation of dispersion: Take 4.6kg of white carbon black in parts by weight and put it into 44L of water, then add 0.4kg of sodium methylene dinaphthalene sulfonate, 0.2kg of sodium lauryl polyoxyethylene ether sulfate, 0.06kg of hydrolyzed casein and 10.5kg of glass microspheres were then stirred at a speed of 3000r / min for 1.5h and then adjusted to a pH value of 10h with 0.2mol / L NaOH solution to obtain a dispersion for subsequent use;

[0023] (2) Preparation of latex mixture: use deionized water to prepare a 100kg latex with a solid content of 40% from natural latex, stir at a speed of 180r / min for 10min, add 42L of the dispersion prepared in step (1), After stirring evenly, add 26L of glacial acetic acid solution with a mass concentration of 8%, and the temperature when the glacial acetic acid solution is added to t...

Embodiment 2

[0028] A polyurethane sieve plate for impact-resistant ore screening, comprising the following steps:

[0029] A substrate for preparing high-temperature-resistant and heat-and-humidity-resistant polyurethane mesh, comprising the following steps:

[0030] (1) Preparation of the dispersion: Take 5.0 kg of white carbon black in 42 L of water, then add 0.5 kg of sodium methylene dinaphthalene sulfonate, 0.3 kg of sodium lauryl polyoxyethylene ether sulfate, 0.08kg of hydrolyzed casein and 12kg of glass microspheres, then stirred at a speed of 3200r / min for 2h and adjusted to a pH value of 10h with 0.2mol / L NaOH solution to obtain a dispersion for subsequent use;

[0031] (2) Preparation of latex mixture: use deionized water to prepare a 100kg latex with a solid content of 40% from natural latex, stir at a speed of 180r / min for 10min, add 42L of the dispersion prepared in step (1), After stirring evenly, add 26L of glacial acetic acid solution with a mass concentration of 10%, an...

Embodiment 3

[0036] A substrate for preparing high-temperature-resistant and heat-and-humidity-resistant polyurethane mesh, comprising the following steps:

[0037] (1) Preparation of dispersion: Take 4.6kg of white carbon black in parts by weight and put it into 44L of water, then add 0.4kg of sodium methylene dinaphthalene sulfonate, 0.2kg of sodium lauryl polyoxyethylene ether sulfate, 0.06kg of hydrolyzed casein and 10.5kg of glass microspheres were then stirred at a speed of 3000r / min for 1.5h and then adjusted to a pH value of 10h with 0.2mol / L NaOH solution to obtain a dispersion for subsequent use;

[0038] (2) Preparation of latex mixture: use deionized water to prepare a 100kg latex with a solid content of 45% from natural latex, stir at a speed of 160r / min for 10min, add 42L of the dispersion prepared in step (1), After stirring evenly, add 26L of glacial acetic acid solution with a mass concentration of 10%, and the temperature of the glacial acetic acid solution when it is add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com