High-resistivity flame-retardant polyvinyl chloride composition for cable material

A technology of flame-retardant polyvinyl chloride and high resistivity, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor thermal stability of materials, poor weather resistance, accelerated aging process, etc. Achieve high insulation performance, excellent flame retardancy, and improve the effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

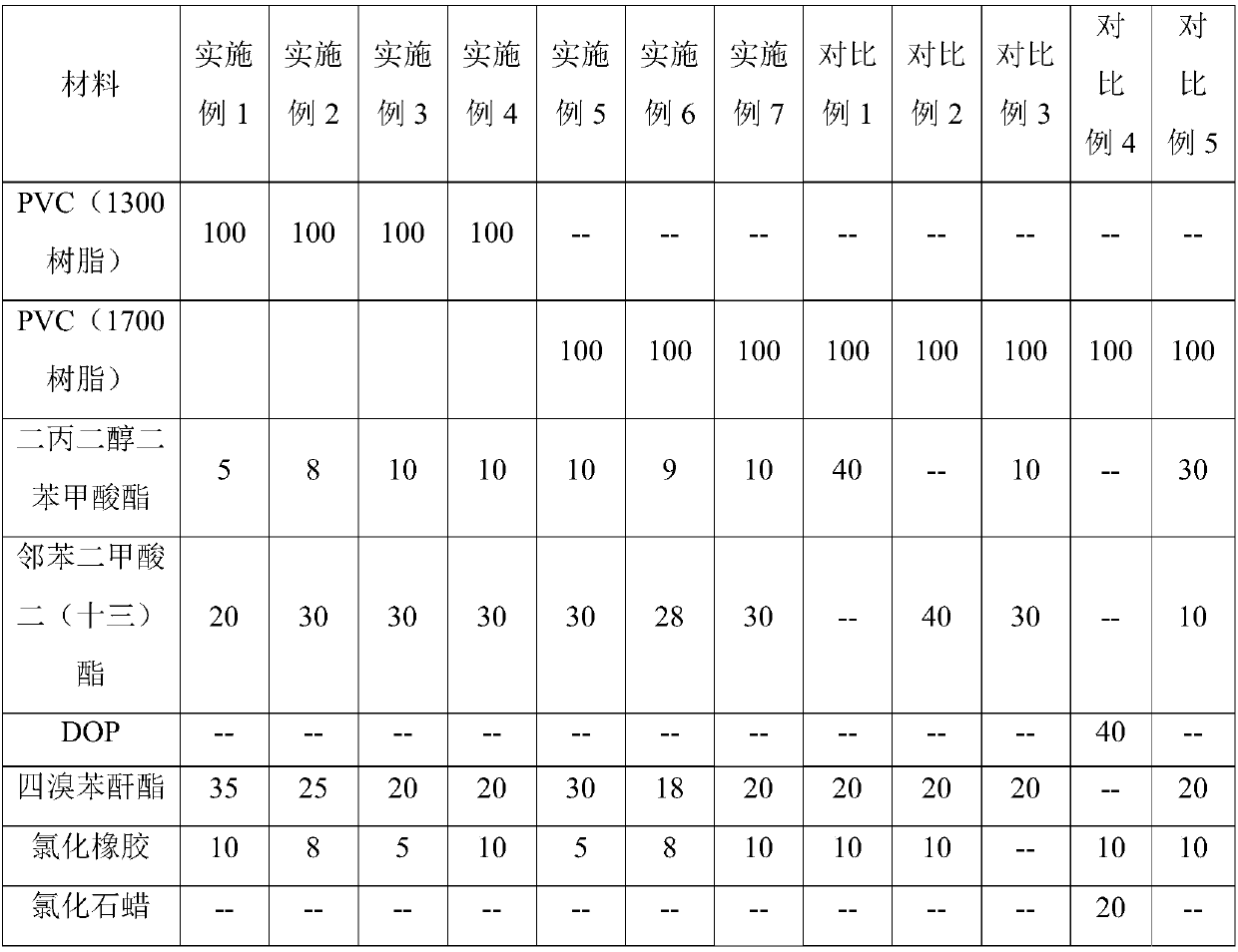

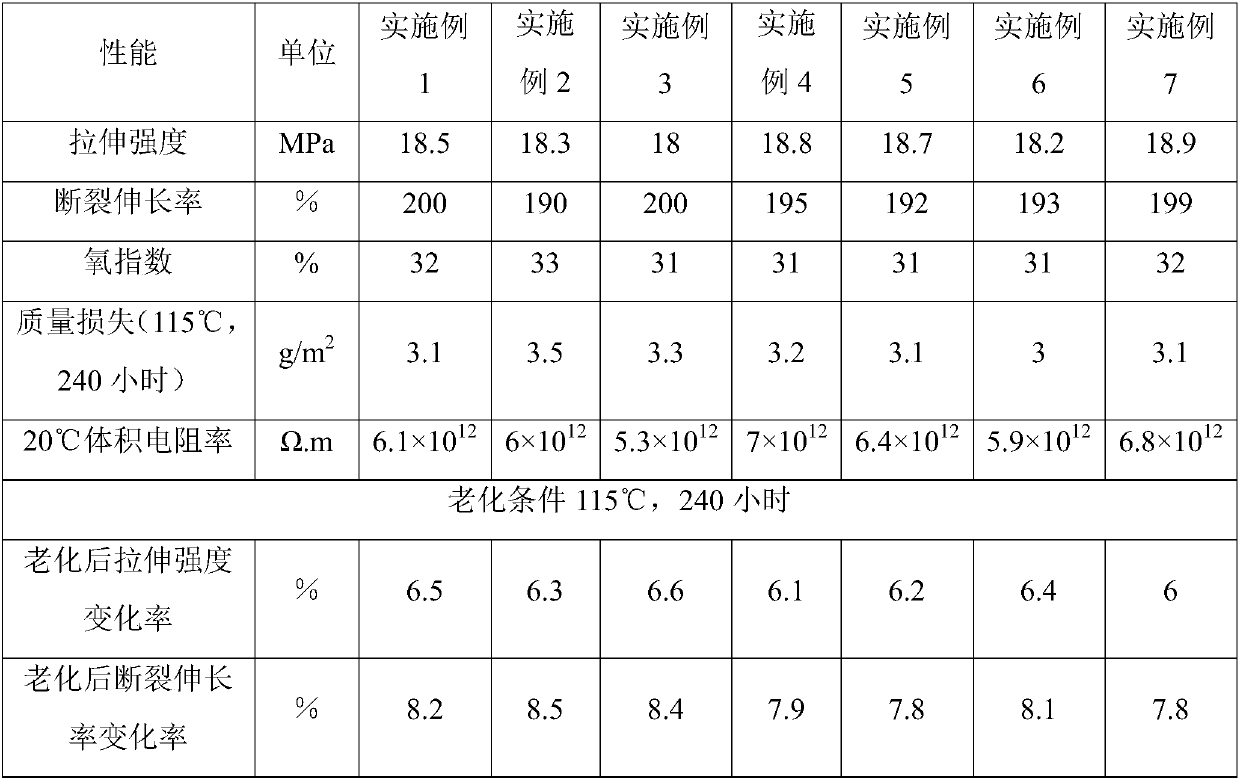

[0023] The present invention will be further described below in conjunction with the examples, but it does not limit the implementation of the present invention.

[0024] The preparation method of embodiment and comparative example is as follows:

[0025] (1) Weigh according to the ratio of raw materials, and then put the weighed materials and additives into the high-low mixing mixer for low-speed stirring. The materials can be added at the same time or sequentially, preferably at the same time. All plasticizers were added in three full additions during stirring. After all the plasticizers are added, high-speed stirring is carried out for 3-6 minutes, and the material is released into the low-speed cold high-speed stirring, and the material is discharged when the temperature is about 45°C.

[0026] (2) Extrude and granulate the mixed materials on a parallel twin-screw extruder, and control the temperature of each zone of the extruder to 100-140°C. Cut into pellets, weigh and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com