Sewage post-stage biochemical process

A sewage and process technology, applied in water/sewage multi-stage treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of high cost of water treatment, low water production rate, and increased sludge output, etc. Achieve the effect of less floor space, improved water quality, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

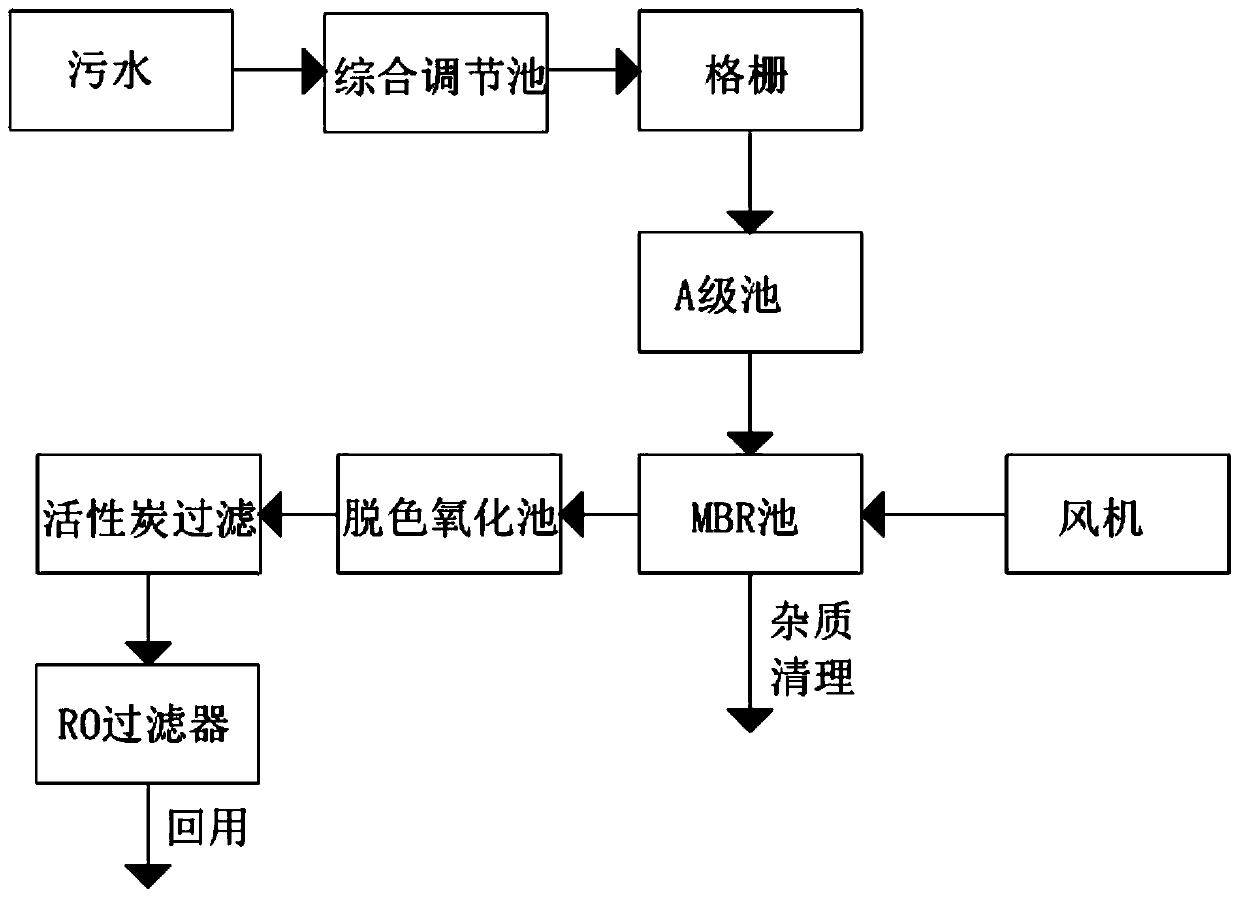

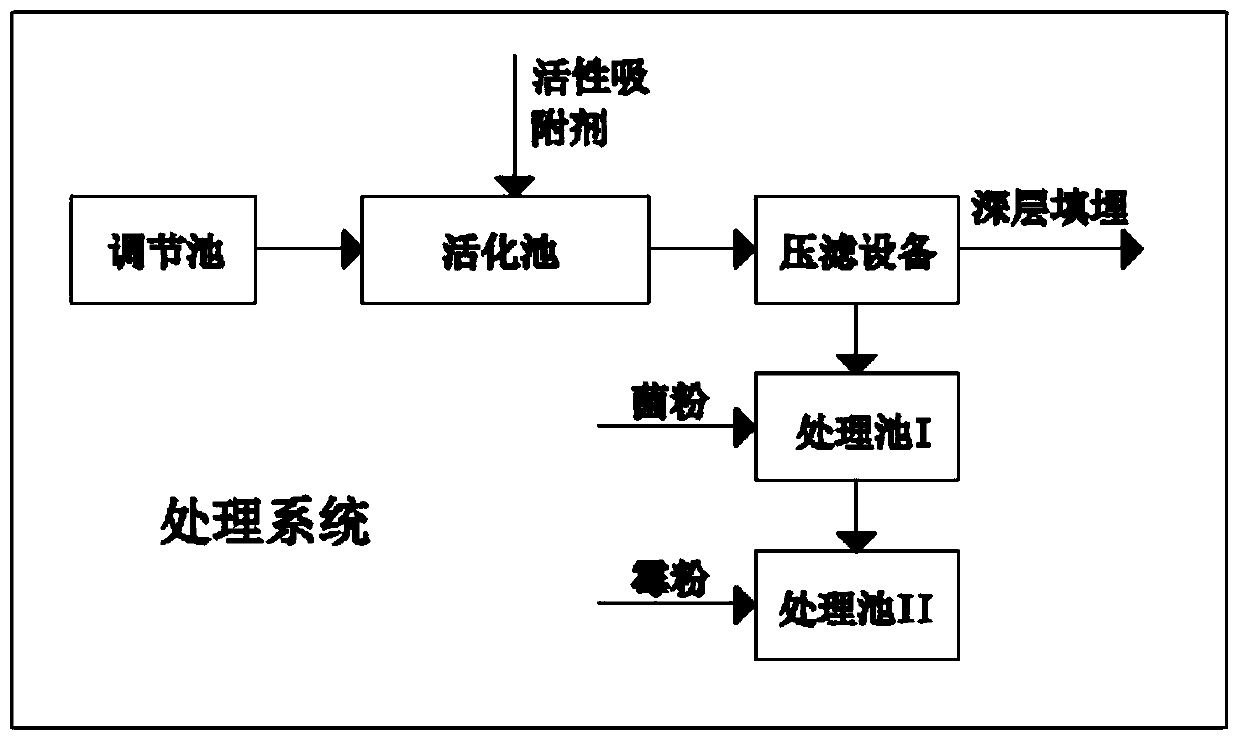

[0032] Embodiment 1, see figure 1 with figure 2 , the present invention provides a technical solution: a post-sewage biochemical process, comprising the following steps;

[0033] Step 1. The sewage is pretreated through the grille. The rotary mechanical grille and stainless steel frame are used, and the grid distance is 1-2mm, to achieve preliminary solid-liquid separation, which can reduce the content of inorganic particulate matter and improve the biochemical properties of sewage. property, get sewage B;

[0034] Step 2, using the treatment system to process the sewage B to obtain sewage C;

[0035] The treatment system includes a regulating tank, a treatment tank I and a treatment tank II, which are used to treat medical linen washing sewage;

[0036] Include the following steps:

[0037] S1. Transport the sewage to the regulating tank through the grid, and adjust the pH value of the sewage to pH ≥ 7;

[0038] S2. Transport the sewage to the activation pool, add activ...

Embodiment 2

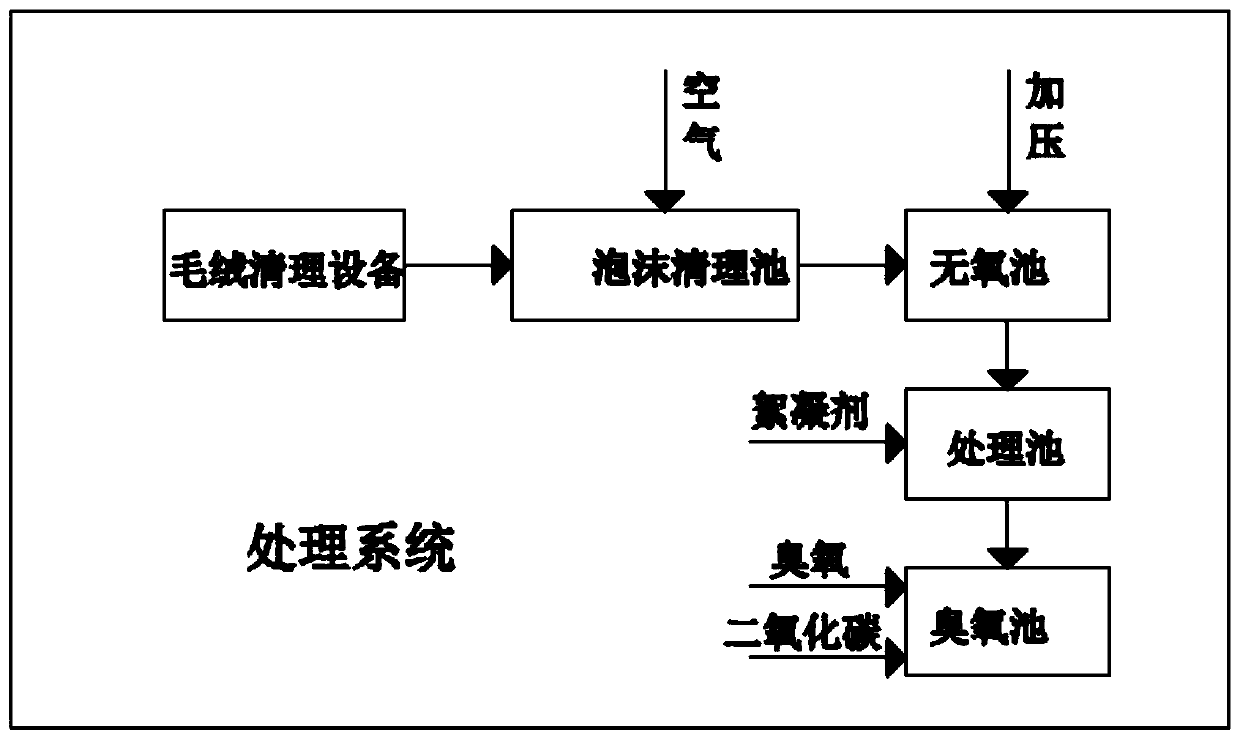

[0051] Example 2, see figure 1 with 3 , the present invention provides a technical solution: a post-sewage biochemical process, comprising the following steps;

[0052] Step 1. Sewage is pretreated through the grille. Rotary mechanical grille and stainless steel frame are used with a grid distance of 5-8mm to achieve preliminary solid-liquid separation, which can reduce the content of inorganic particulate matter and improve the biochemical properties of sewage. property, get sewage A;

[0053] Step 2, using the treatment system to process sewage A to obtain sewage B;

[0054] The treatment system includes lint cleaning equipment, foam cleaning tanks, anaerobic tanks, treatment tanks and ozone tanks, which are used to treat washing sewage;

[0055] Include the following steps:

[0056] S1. Transport the sewage to the lint cleaning equipment through the grid to remove the lint in the sewage;

[0057] S2. Transport the sewage to the foam cleaning tank, inject air, and make ...

Embodiment 3

[0069] Example 3, see figure 1 with 4 , the present invention provides a technical solution: a post-sewage biochemical process, comprising the following steps;

[0070] Step 1. The sewage is pretreated through the grille. The rotary mechanical grille and stainless steel frame are used, and the grid distance is 6mm, to achieve preliminary solid-liquid separation, which can reduce the content of inorganic particulate matter and improve the biodegradability of sewage. Get sewage A;

[0071] Step 2, using the treatment system to process sewage A to obtain sewage B;

[0072] The treatment system includes CASS pool, disinfection pool, sewage lifting pump, sludge thickening pool, used to treat toxic sewage;

[0073] Include the following steps:

[0074] S1. The sewage is transported to the CASS tank through the grid, so that the sewage is completely mixed with the activated sludge in the CASS tank, and the soluble organic matter in the sewage is adsorbed by the microorganisms in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com