Preparation method for liquor residual biomass fuel rod

A technology of biomass fuel and distiller's grains, applied in the energy field, can solve the problems of easy breeding of harmful bacteria and mosquitoes, pollution of surrounding soil, water and air, etc., to achieve the effect of high combustion and utilization value, easy molding and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

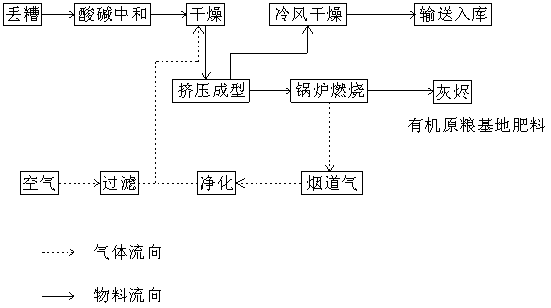

Image

Examples

Embodiment 1

[0018] A method for preparing distiller's grain biomass fuel rods, which includes: 1) acid-base neutralization: using quicklime as a mixture to adjust the pH to 6; 2) hot air drying: using flue gas discharged from waste grain boilers or The generated high-temperature steam is dried by the hot air generated by the heat exchanger, and the flue gas discharged from the waste boiler is purified; 3) Hot press forming: at 140°C, the forming pressure is 4MPa, and the moisture content is Compression molding under the condition of 5%; 4) 50kg packaging for storage.

Embodiment 2

[0020] A method for preparing distiller's grain biomass fuel rods, which includes: 1) acid-base neutralization: use quicklime as a mixture, and adjust the pH to 8; 2) hot air drying: use flue gas discharged from a waste grain boiler or a The generated high-temperature steam is dried by the hot air generated by the heat exchanger, and the flue gas discharged from the waste boiler is purified; 3) Hot press molding: at 180°C, the molding pressure is 8MPa, and the moisture content is Compression molding under the condition of 15%; 4) 100kg packaging for storage.

Embodiment 3

[0022] A method for preparing distiller's grain biomass fuel rods, which includes: 1) acid-base neutralization: use quicklime as a mixture, and adjust the pH to 7; 2) hot air drying: use flue gas discharged from a waste grain boiler or a The generated high-temperature steam is dried by the hot air generated by the heat exchanger, and the flue gas discharged from the waste boiler is purified; 3) Hot press forming: at 1460°C, the forming pressure is 6MPa, and the moisture content is Compression molding under 10% condition; 4) 25kg packaging for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com