Treatment method of trivalent chromium passivation wastewater

A treatment method and technology of trivalent chromium, applied in water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc. Short production time and other problems, to achieve good market application prospects, reduce COD, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

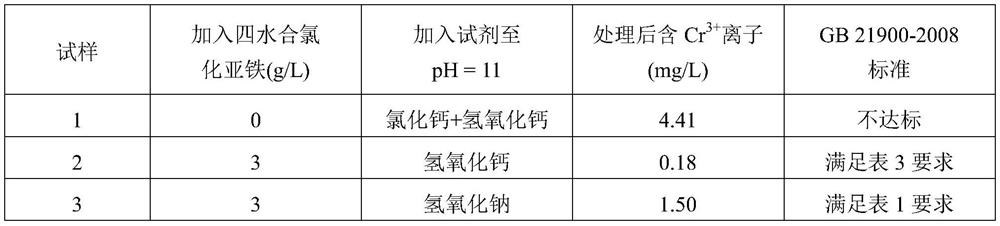

[0040] Embodiment 1: process the trivalent chromium passivation waste water containing trivalent chromium ion 100mg / L

[0041] The present embodiment provides a kind of treatment method of trivalent chromium passivation waste water, to process the trivalent chromium chromium plating waste water containing trivalent chromium ion 100mg / L; comprise the following steps:

[0042] Step 1, add ferrous chloride

[0043] The trivalent chromium passivation wastewater is transported from the wastewater regulating tank to the feeding tank, and 10L of ferrous chloride solution is added to each ton of wastewater, and the pool liquid is stirred with a stirrer.

[0044] Step 2. Precipitation of complexing agents and heavy metal ions

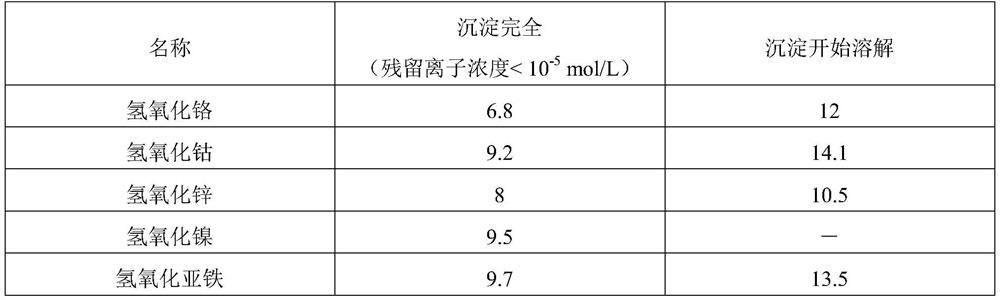

[0045] The wastewater flows from the feeding tank into the sedimentation tank, and the tank liquid is stirred with a stirrer, and the pH of the wastewater is adjusted to 10-11 by adding lime emulsion. The released trivalent chromium ions, cobalt ions, zinc ion...

Embodiment 2

[0052] Embodiment 2: process the trivalent chromium passivation waste water containing trivalent chromium ion 200mg / L

[0053] The present embodiment provides a kind of treatment method of trivalent chromium passivation waste water, to process the trivalent chromium chromium plating waste water containing trivalent chromium ion 200mg / L, malic acid 800mg / L; comprise the following steps:

[0054] Step 1, add ferrous chloride

[0055] Transfer the trivalent chromium passivation wastewater adjustment pool to the feeding pool, stir the pool liquid with a stirrer, and add 20L of ferrous chloride solution per ton of wastewater.

[0056] Step 2. Precipitation of complexing agents and heavy metal ions

[0057] The wastewater flows from the feeding tank into the sedimentation tank, and the tank liquid is stirred with a stirrer, and the pH of the wastewater is adjusted to 10-11 by adding lime emulsion. The released heavy metal ions such as trivalent chromium form hydroxide precipitates. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com