Precious metal silicon molecular sieve and preparation method and application thereof

A silicon molecular sieve and molecular sieve technology are applied in the field of precious metal silicon molecular sieve and its preparation and application, which can solve the rare precious metal silicon molecular sieve and other problems, and achieve the effects of good catalytic oxidation effect, good stability and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073](1) At 25°C, stir and mix the silica sol and palladium chloride for 30 minutes, then age at 80°C for 12 hours, and dry at 120°C for 6 hours to obtain the aged material;

[0074] (2) At 60° C., the alkali source template (25% by weight of tetrapropylammonium hydroxide) was added to the material after the aging treatment and stirred and contacted for 0.5 h to obtain a mixture to be crystallized (during this contact process, Add water or not add water according to needs, if the feed intake of step (1) can meet the feed intake requirements of water, then no need to add water, if not, then add water, the rest of the embodiments are similar, no need to repeat the description); the molar composition of the mixture to be crystallized Than for, SiO 2 : Tetrapropylammonium hydroxide : Pd : H 2 O=100:10:1.5:500; the above-mentioned mixture to be crystallized was transferred into a sealed stainless steel reaction kettle, and crystallized at a temperature of 170°C and autogenous pre...

Embodiment 2

[0076] (1) At 25°C, stir and mix the silica sol and palladium chloride for 30 minutes, then age at 80°C for 12 hours, and dry at 120°C for 6 hours to obtain the aged material;

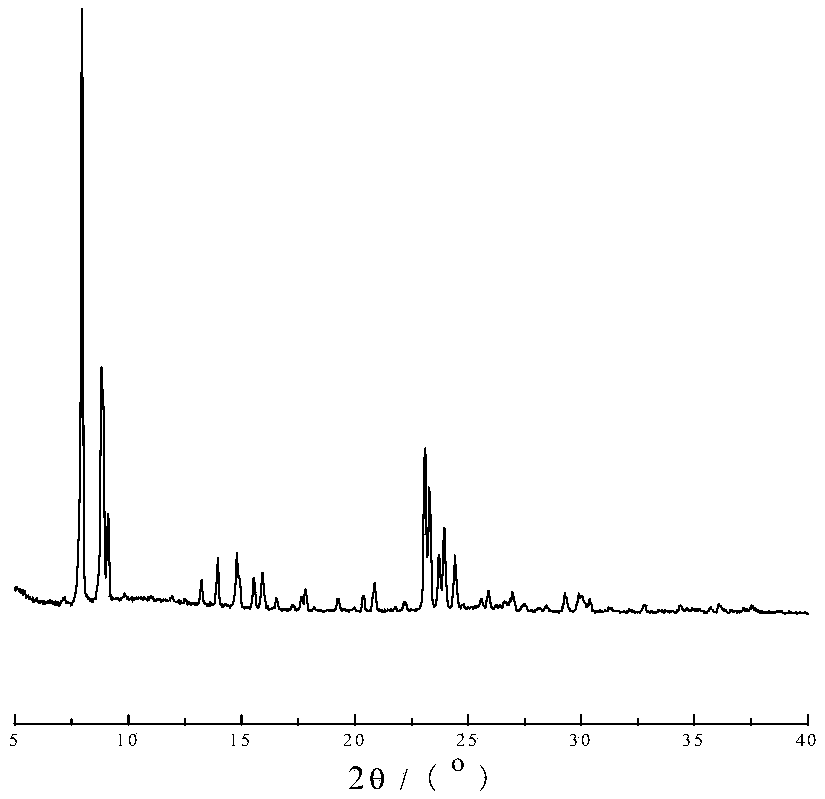

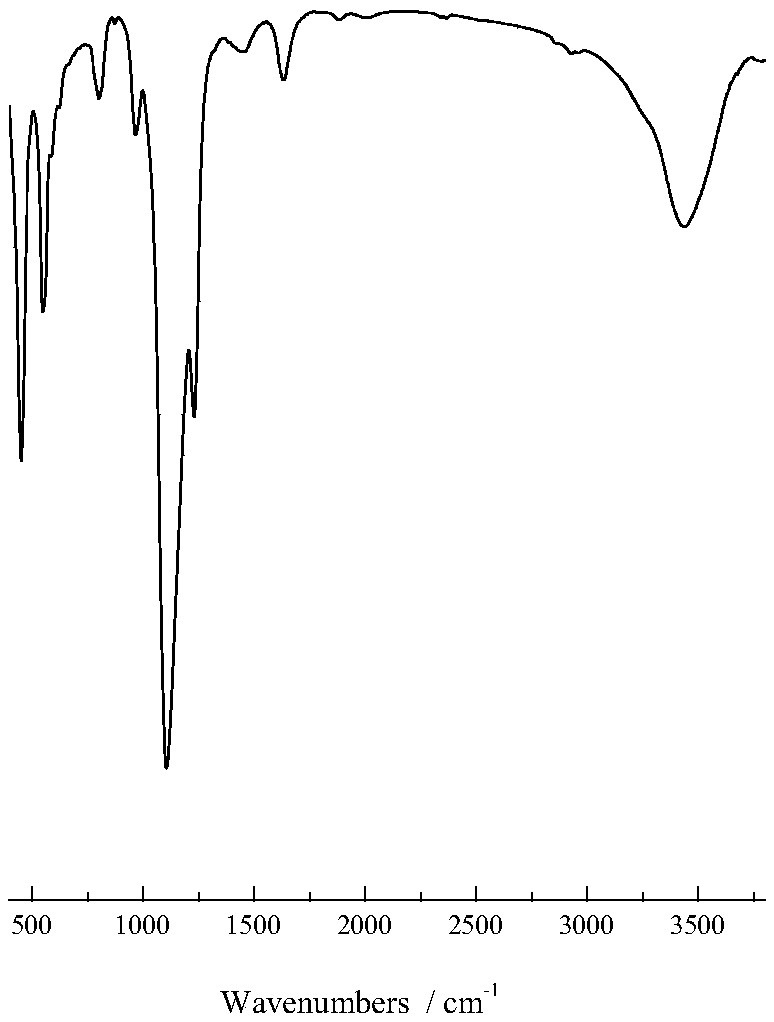

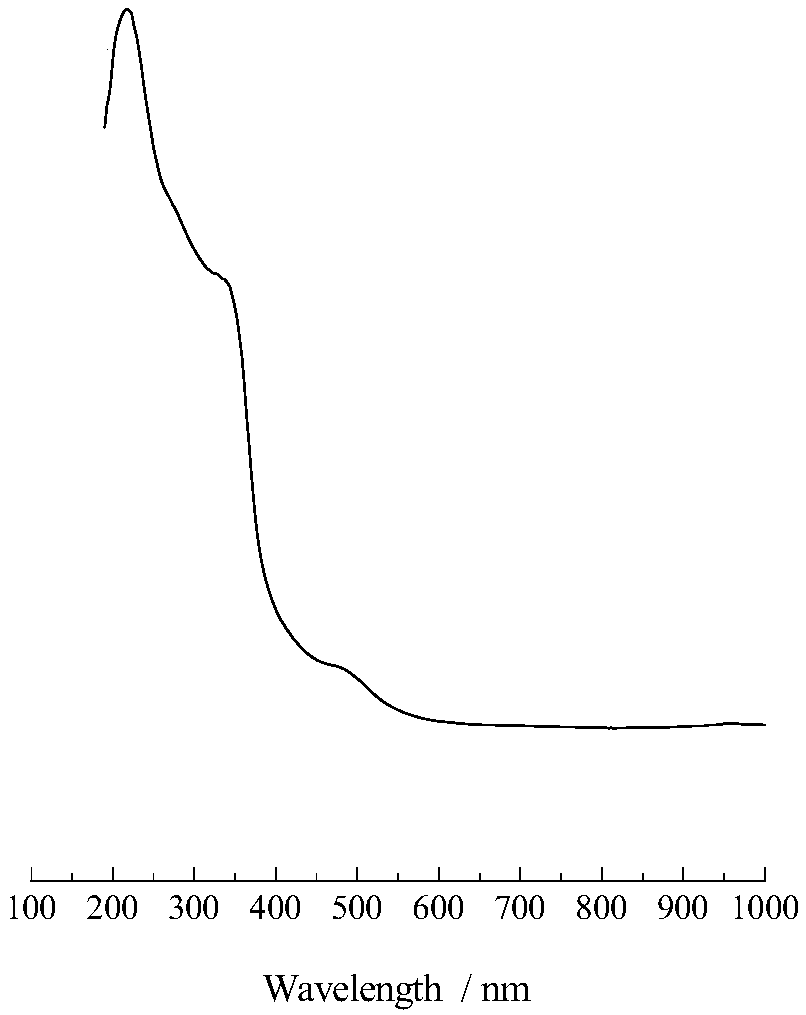

[0077] (2) At 25°C, add the alkali source template (tetrapropylammonium hydroxide) to the material after the aging treatment and stir for 0.5h to obtain the mixture to be crystallized; the molar ratio of the mixture to be crystallized is, SiO 2 : Tetrapropylammonium hydroxide : Pd : H 2 O=100:15:0.1:700; the above-mentioned mixture to be crystallized was transferred into a sealed stainless steel reaction kettle, and crystallized at a temperature of 160°C and autogenous pressure for 72 hours, and the resulting crystallized product was filtered, washed with water, and dried at 110°C. °C for 120 min, and then calcined at 550 °C for 3 h to obtain noble metal silicon molecular sieves. The XRD spectrum, FT-IR spectrum, UV-Vis spectrum, TEM photo of this molecular sieve are similar to embodiment 1; At 25 ℃,...

Embodiment 3

[0079] (1) Stir and mix the silica sol and palladium acetate for 30 minutes at 40°C, then age at 100°C for 12 hours, and dry at 150°C for 5 hours to obtain the aged material;

[0080] (2) At 25°C, the alkali source template (tetrapropylammonium hydroxide) is added to the material after the aging treatment and stirred for 0.5h to obtain the mixture to be crystallized; the molar ratio in the mixture to be crystallized is , SiO 2 : Tetrapropylammonium hydroxide : Pd : H 2 O=100:12:2:600; the above-mentioned mixture to be crystallized was transferred into a sealed stainless steel reactor, and crystallized at a temperature of 170°C and autogenous pressure for 24 hours, and the obtained crystallized product was filtered, washed with water, and Dry at 110°C for 120 minutes, and then bake at 550°C for 3 hours to obtain noble metal silicon molecular sieves. The XRD spectrum, FT-IR spectrum, UV-Vis spectrum, TEM photo of this molecular sieve are similar to embodiment 1; At 25 ℃, P / P ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com