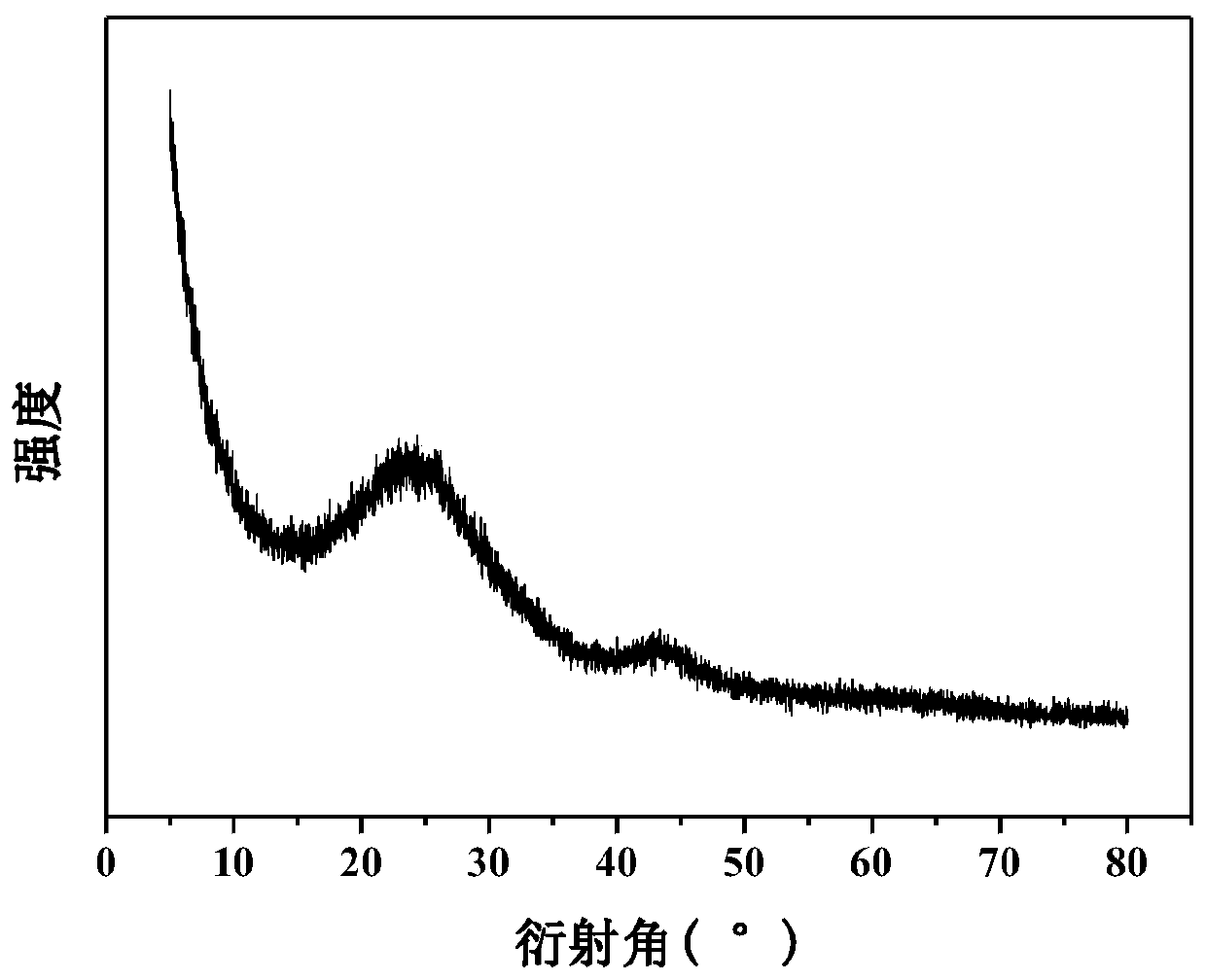

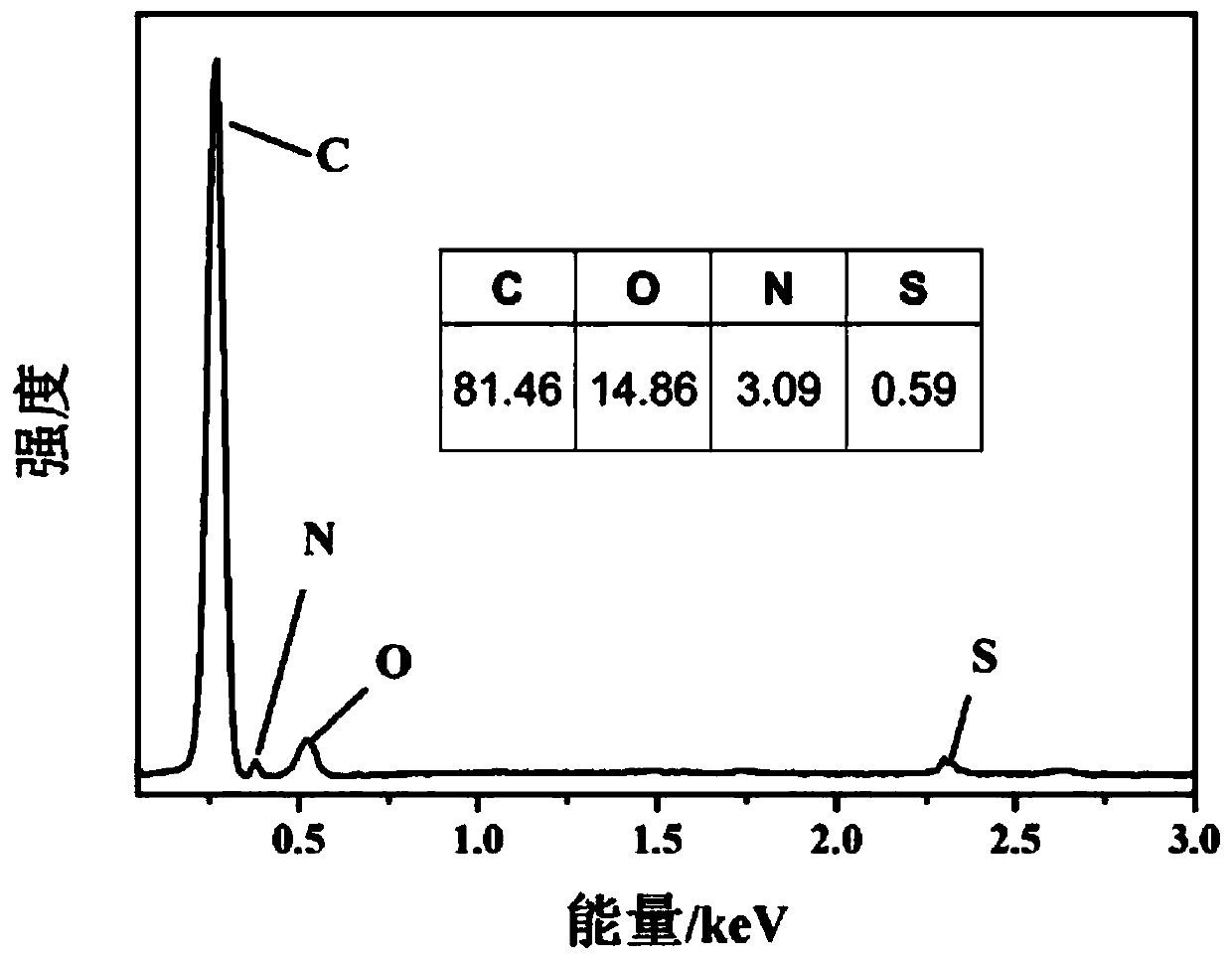

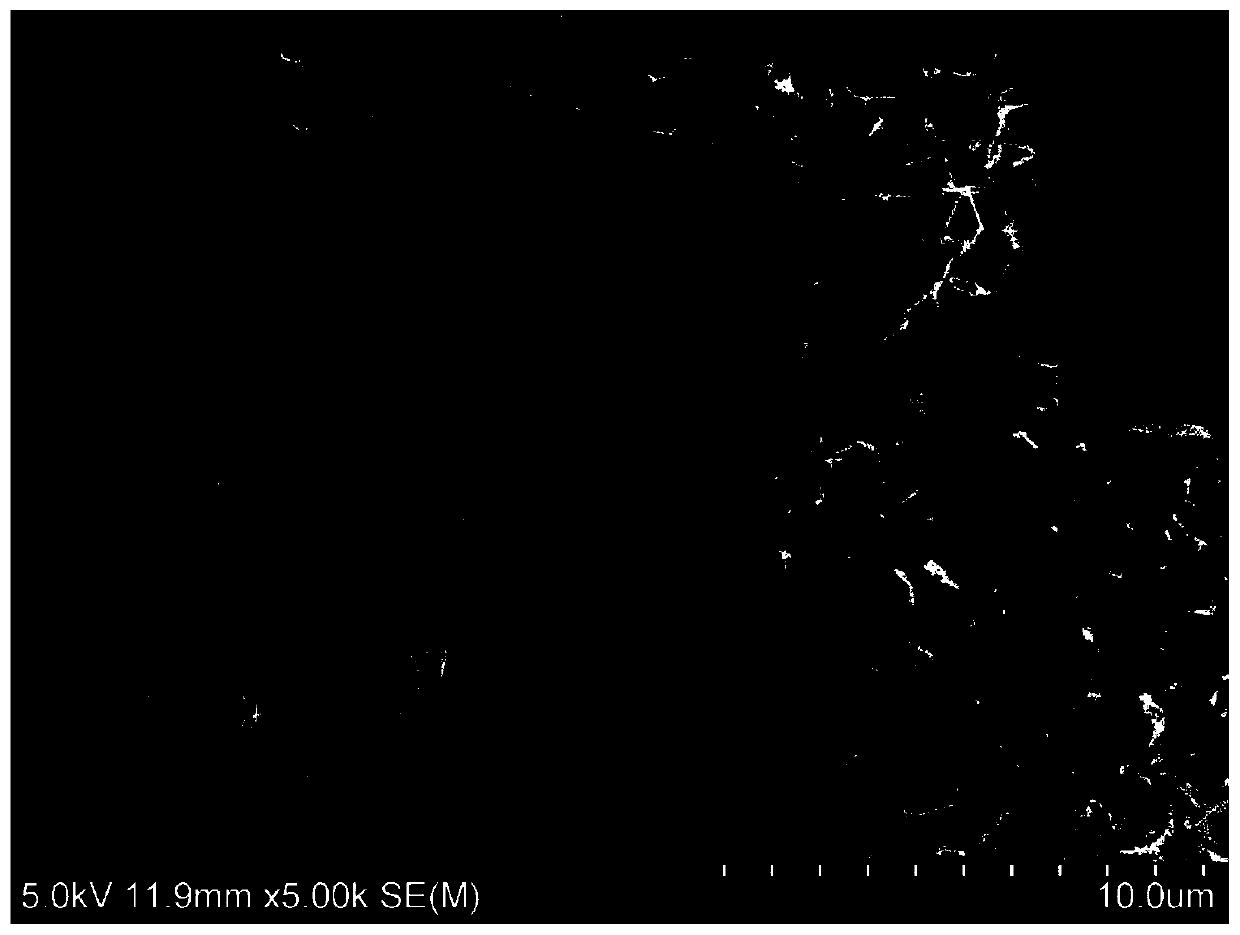

N, S co-doped bagasse nanosheet-shaped mesoporous structure biomass charcoal and preparation method thereof

A mesoporous structure and nano-sheet technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems that have not been reported, and achieve the effect of low technical difficulty, good chemical properties, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 10 g of bagasse, wash it with tap water to remove surface impurities, then wash it twice with deionized water, put it into a constant temperature blast drying oven at 80° C., and dry it at a constant temperature to obtain washed and dried bagasse.

[0022] (2) the bagasse of 3g step (1) gained is put into the liner of the polytetrafluoroethylene reactor of 100mL, add 60mL concentration and be the potassium hydroxide solution of 2.5mol / L, after putting on the steel shell and tightening, Put it into a constant temperature oven, heat it at a constant temperature of 160°C for 14 hours, and then take it out after cooling naturally. Pour off the brown liquid in the inner pot, take out the solid matter in the inner pot, wash the solid matter with deionized water until it is neutral, and put it in Dry in a constant temperature blast drying oven at 60°C to obtain a dry gray flocculent precursor.

[0023] (3) Add 100 mL of deionized water to the mixture of the gray floc...

Embodiment 2

[0028] (1) Weigh 10 g of bagasse, wash it with tap water to remove surface impurities, wash it twice with deionized water, put it into a constant temperature blast drying oven at 80° C., and dry it at a constant temperature to obtain washed and dried bagasse.

[0029] (2) the bagasse of 3g step (1) gained is put into the liner of the polytetrafluoroethylene reactor of 100mL, add 60mL concentration and be the potassium hydroxide solution of 2.5mol / L, after putting on the steel shell and tightening, Put it into a constant temperature oven, heat it at 160°C for 14 hours, and then take it out after cooling naturally. Pour off the brown liquid in the inner pot, take out the solid matter in the inner pot, wash the solid matter with deionized water until it is neutral, and put it in Dry in a constant temperature blast drying oven at 60°C to obtain a dry gray flocculent precursor.

[0030] (3) Add 100 mL of deionized water to the mixture of the gray flocculent precursor obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com