Automatic storage production line for mattress

A technology for production lines and mattresses, which is applied to conveyor control devices, stacking of objects, conveyors, etc., can solve the problems of increasing the area of long production lines, uneven stacking, and high labor intensity, reducing The effect of manual labor, space avoidance, and footprint reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

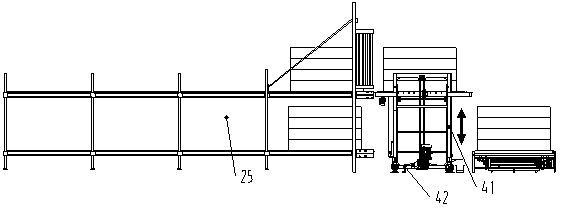

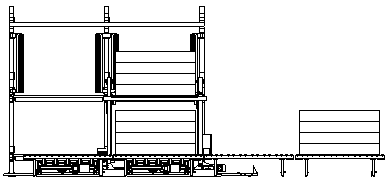

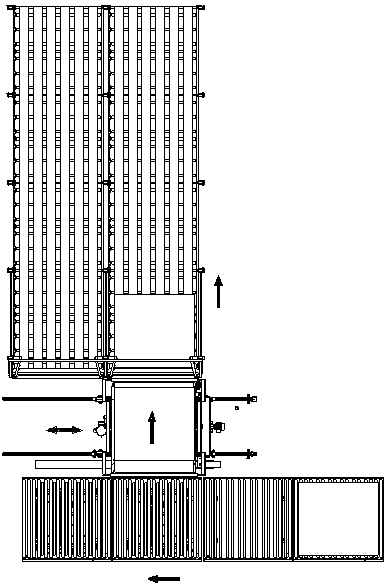

[0029] like Figure 1-Figure 7 The shown one is used for mattress automatic storage production line, including

[0030] A conveying assembly, the conveying assembly includes a conveying support 1, on which several conveying rollers 11 distributed side by side along the conveying direction of the mattress are installed, and the conveying rollers 11 are driven to rotate by the conveying motor installed on the conveying support 1, A third inductive switch is provided at the discharge port of the conveying support 1. Through the setting of the third inductive switch, the conveying position of the mattress on the conveying support 1 can be detected, which provides a good foundation for subsequent automation.

[0031] A storage assembly, the storage assembly includes a storage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com