Eucalyptus veneer veneered wood-based composite board and preparation method thereof

A composite board and veneer technology, which is applied in the jointing of wooden veneers, wood layered products, wood processing equipment, etc., can solve the problems of insufficient local pressure bearing capacity, extrusion fracture, low compressive strength of composite boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

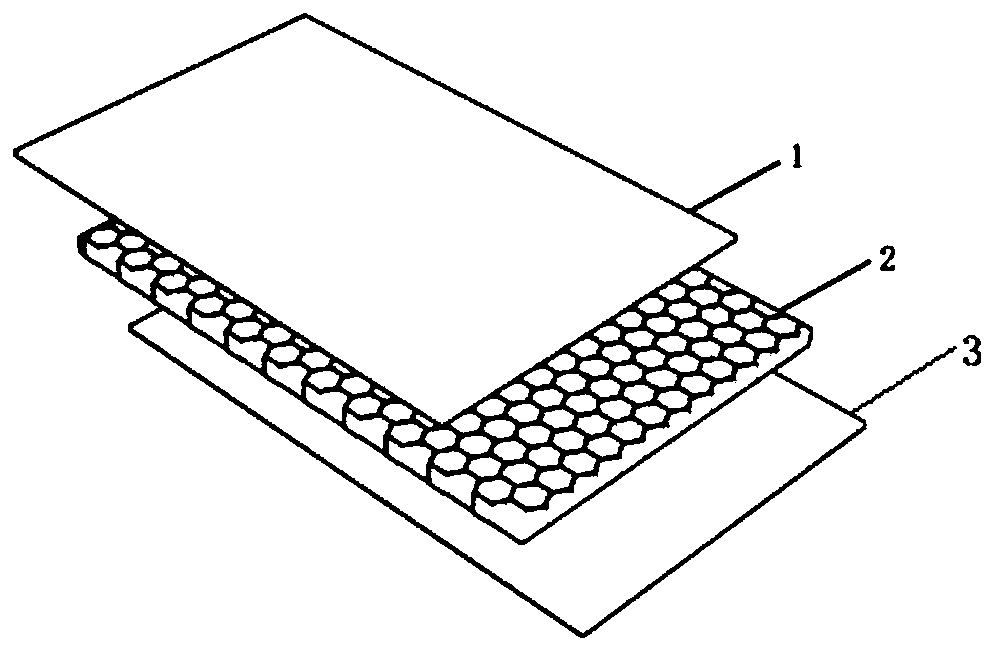

[0043] The present invention also provides a preparation method of eucalyptus veneer veneer wood-based composite board, comprising the following steps:

[0044] After mixing the inorganic adhesive, wood fiber and water, the wood fiber inorganic slurry is obtained;

[0045] Spraying the wood fiber inorganic slurry on the buckwheat husk surface to obtain filler;

[0046] Filling the filler into the pores of the core of the honeycomb panel, and performing the first hot pressing to obtain the honeycomb composite layer;

[0047] The eucalyptus veneer layer is bonded to both sides of the honeycomb composite layer, and the second hot pressing is carried out to obtain the eucalyptus veneer veneer wood-based composite board.

[0048] The invention mixes the inorganic adhesive, wood fiber and water to obtain the wood fiber inorganic slurry.

[0049] The present invention does not have any special limitation on the mixing method, and a mixing method well known to those skilled in the a...

Embodiment 1

[0068] 1) Mix and stir the inorganic adhesive with 40-mesh wood fiber and water to prepare a uniform wood fiber inorganic slurry with a viscosity of 130MPa·s. The weight ratio of inorganic adhesive to wood fiber is 70:30.

[0069] 2) spraying the wood fiber inorganic slurry onto the buckwheat husks with a spray gun, and stirring the wood fiber inorganic slurry while spraying, so that the wood fiber inorganic slurry is evenly sprayed on the surface of the buckwheat husks to obtain the buckwheat husks, wood fibers and inorganic adhesive The filler is mixed, and the weight ratio of wood fiber inorganic slurry to buckwheat husk is 40:60.

[0070] 3) Lay the steel backing plate on the billet forming platform, lay the paper honeycomb core on the steel backing plate, and then fill the above-mentioned fillers into the honeycomb holes, the filling amount is 500kg / m 3 . Put a steel backing plate on the top of the filled honeycomb panel core, send it to the hot press for the first hot p...

Embodiment 2

[0079] 1) Mix and stir the inorganic adhesive with 50 mesh wood fiber and water to prepare a uniform wood fiber inorganic slurry with a viscosity of 110MPa·s. The weight ratio of inorganic adhesive to wood fiber is 60:40.

[0080] 2) spraying the wood fiber inorganic slurry onto the buckwheat husks with a spray gun, and stirring the wood fiber inorganic slurry while spraying, so that the wood fiber inorganic slurry is evenly sprayed on the surface of the buckwheat husks to obtain the buckwheat husks, wood fibers and inorganic adhesive The filler is mixed, and the weight ratio of wood fiber inorganic slurry to buckwheat husk is 35:65.

[0081] 3) Lay the steel backing plate on the billet forming platform, lay the aluminum honeycomb core on the steel backing plate, and then fill the above-mentioned fillers into the honeycomb holes, the filling amount is 300kg / m 3 . Put a steel backing plate on top of the filled honeycomb panel core, send it to the hot press for the first hot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com