Hot melt device for producing thermoplastic polyurethane elastomers

A technology for thermoplastic polyurethane and production heat, which is applied in the field of hot-melt devices for thermoplastic polyurethane elastomer production, can solve the problems of long time required for hot-melting and reduce the practicability of the device, and achieves improved convenience, practicability, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

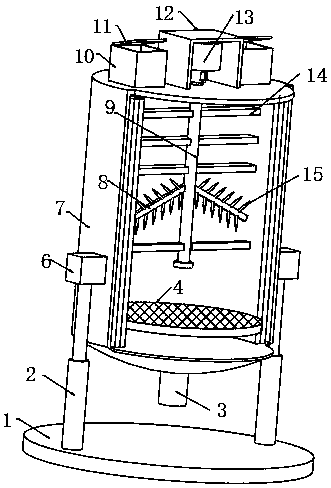

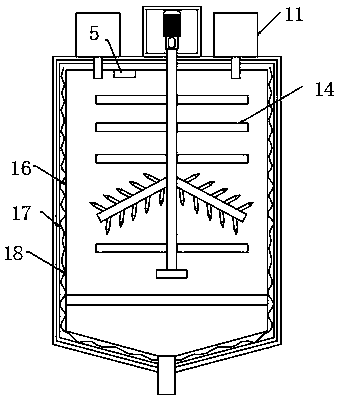

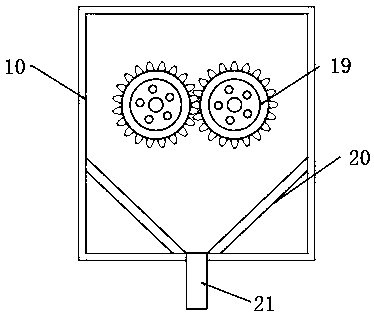

[0029] refer to Figure 1-3 , a thermoplastic polyurethane elastomer production hot-melt device, including a base plate 1, both sides of the top outer wall of the base plate 1 are welded with hydraulic rods 2, and the top outer wall of the hydraulic rod 2 is welded with a fixed block 6, and the outer wall of the fixed block 6 is welded There is a hot melt tank body 7, and the top outer wall of the hot melt tank body 7 is welded with a feed box 10, the top outer wall of the feed box 10 is connected with a heat preservation cover 11 through a hinge, the bottom inner wall of the feed box 10 and the hot melt tank body The top inner wall of 7 is connected with the same feed pipe 21 through a flange, and the bottom inner wall of the feed box 10 is welded with a blanking plate 20 on both sides, and the inner wall of one side of the feed box 10 is connected with a second rotating rod through a bearing. , and the outer wall of the second rotating rod is welded with a crushing roller 19...

Embodiment 2

[0033] refer to Figure 4 , a thermoplastic polyurethane elastomer production hot-melt device, also includes a slot 23 welded to the inner wall of the hot-melt tank body 7, the inner wall of the slot 23 is clamped with a block 22, and the top outer wall of the block 22 is fixed by a screw On the top outer wall of the filter plate 4 , the locking groove 23 and the locking block 22 are engaged with each other, which facilitates the installation and removal of the filter plate 4 and improves the convenience of the device.

[0034] Working principle: connect the equipment to the power supply, connect the hydraulic rod 2 to the hydraulic system, adjust the length of the hydraulic rod 2 according to the height of the staff, put the material into the material box 10, turn on the second motor, and use the crushing roller 19 to crush the material , the pulverized material enters the hot melt tank body 7 from the feed pipe 21, the heating wire 18 is turned on, the motor 13 is turned on,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com