Micro-hemispherical resonator gyro structure, assembly method and wafer fixture

A hemispherical resonant gyroscope and hemispherical resonance technology, which are applied in microstructure devices, processing microstructure devices, and microelectronic microstructure devices, etc., can solve the problems of low assembly accuracy, low assembly efficiency, poor assembly consistency, etc., and achieve assembly difficulty. Low, reduce assembly error, eliminate the effect of partial error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A wafer-level assembly method for a micro-hemispherical resonant gyro structure, as shown in Figure 3, is suitable for high-precision assembly of a micro-hemispherical resonant gyro structure driven by a bottom plane electrode, and specifically includes the following steps:

[0048] Step 1, as shown in Figure 3 (a), open at least two through glass sheet positioning holes 9 on the edges of both ends of a plurality of glass sheets 8 containing the micro-hemispherical resonant structure 1, for realizing the micro-hemispherical resonant structure 1 in a circle Positioning on the sheet holder 10; in this embodiment, laser cutting is used to complete the opening of the glass sheet positioning holes 9, the number is two, and they are arranged symmetrically along the central axis of the glass sheet 8.

[0049] Step 2, as shown in Figure 3 (b), align the plurality of glass sheets 8 obtained after the processing in step 1 with the wafer holder 10 on the basis of the glass sheet po...

Embodiment 2

[0065] like figure 1 A kind of micro-hemispheric resonant gyroscope structure shown in and 3, comprises micro-hemispherical resonant structure 1, described micro-hemispherical resonant structure 1 is fixedly connected with planar electrode 2 through the anchor point of the center, in guaranteeing that micro-hemispherical resonant structure 1 and disc fixture 10. While having a sufficient contact area, it is compatible with the subsequent process. The planar electrode 2 is used to extract the vibration signal of the micro-hemispheric resonant gyro structure, and is an essential part of the micro-hemispheric resonant gyro structure;

[0066] There is a gap between the two ends of the micro-hemispherical resonant structure 1 and the planar electrode 2, and the planar electrode 2 is provided with grooves corresponding to the two ends of the micro-hemispheric resonant structure 1 to form a gap for realizing the micro-hemispheric resonant gyro structure Electrostatic drive and capac...

Embodiment 3

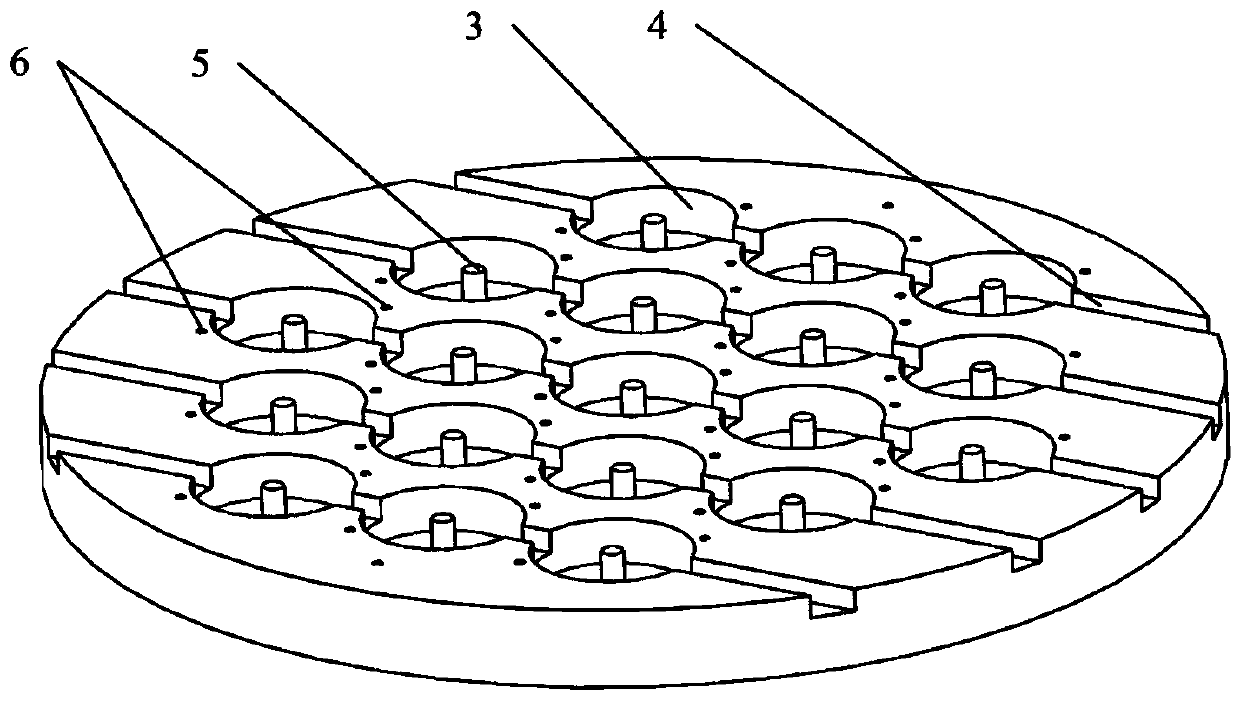

[0076] like figure 2 A wafer clamp of a micro-hemispherical resonant structure shown in -3 includes a clamp body, and the clamp body is provided with a plurality of space-avoiding grooves 3 that cooperate with the micro-hemispherically resonant structure 1, and the space-avoiding grooves 3 There are outlet grooves 4 on both sides, which are used to realize the inflow of gas and / or liquid required in the assembly process and the outflow of waste gas and / or waste liquid, so as to ensure the normal progress of the processing process;

[0077] The geometric center of each said avoidance groove 3 is provided with a fixed cylinder 5, that is, a fixed cylinder 5 is correspondingly installed in one avoidance groove 3, which is used to fix the micro-hemispherical resonant structure 1, and the fixed cylinder 5 The height is consistent with the depth of the escaping groove 3, which is convenient for placing the glass sheet 8 to pressurize the glass sheet 8 by the plane plate 7;

[0078...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com