Pressure control method for hydraulic system of hybrid transmission

A hydraulic system and hybrid technology, applied in the direction of transmission control, components with teeth, transmission parts, etc., can solve the problems affecting the performance and service life of the gearbox, affecting the use effect of the gearbox, etc., to reduce failures. Eliminate difficulty, simple structure, good safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

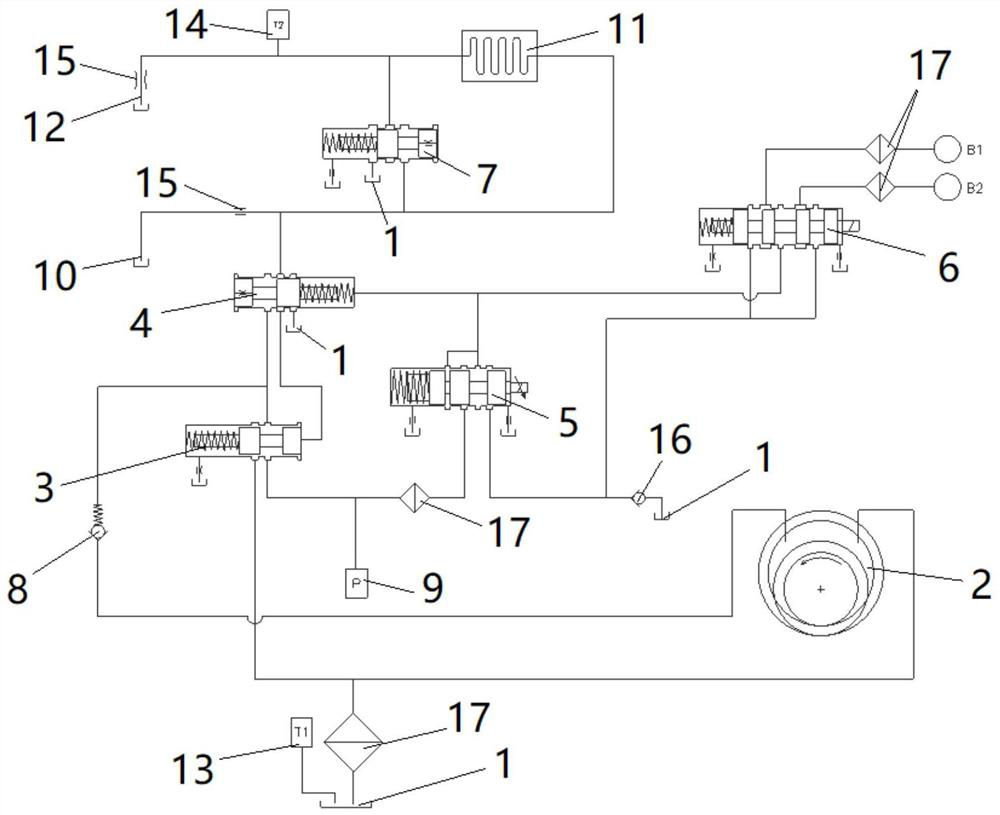

[0030] A pressure control method for a hydraulic system of a hybrid transmission, such as figure 1As shown, the hydraulic system of the hybrid transmission includes a hydraulic oil storage device 1, an electric hydraulic pump 2, a cooling overflow valve 3, a main pressure regulating valve 4, an electromagnetic pressure regulating valve 5, an electromagnetic reversing valve 6 and a bypass valve 7, The oil suction port of the electric hydraulic pump 2 is connected to the oil outlet of the hydraulic oil storage device 1, the oil outlet of the hydraulic oil storage device 1 is provided with a first temperature sensor 13, and the oil outlet of the electric hydraulic pump 2 is connected in series with the first The check valve 8 is respectively connected with the oil inlet of the cooling overflow valve 3 and the oil inlet of the main pressure regulating valve 4, and the oil outlet of the cooling overflow valve 3 is connected with the oil inlet of the electromagnetic pressure regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com