Steel chained pin roller holder used for pin roller linear guide rail

A roller linear guide rail and cage technology, applied in the cage field, can solve the problems of roller jamming, falling off, breakage, etc., and achieve the effect of high use strength, good flexibility and elasticity, and good rotation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

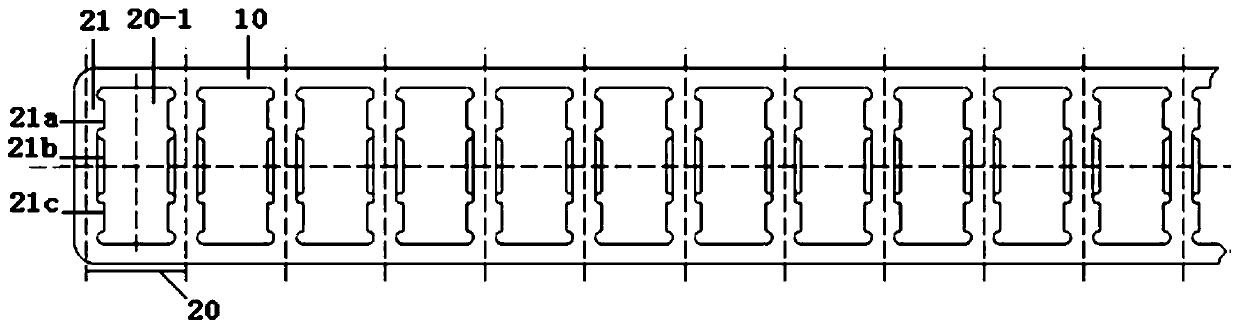

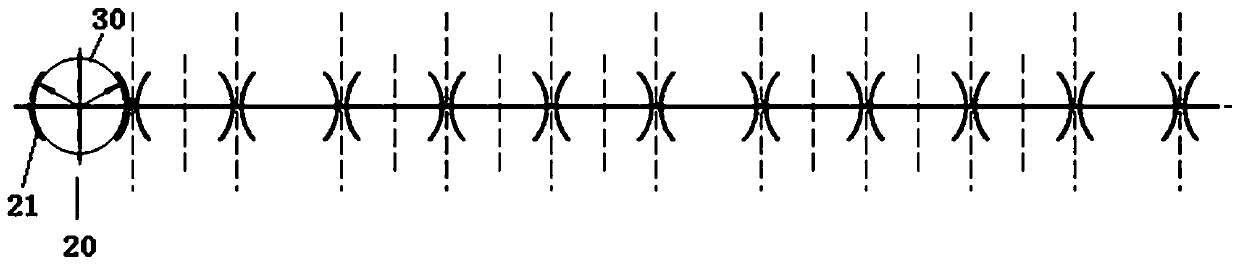

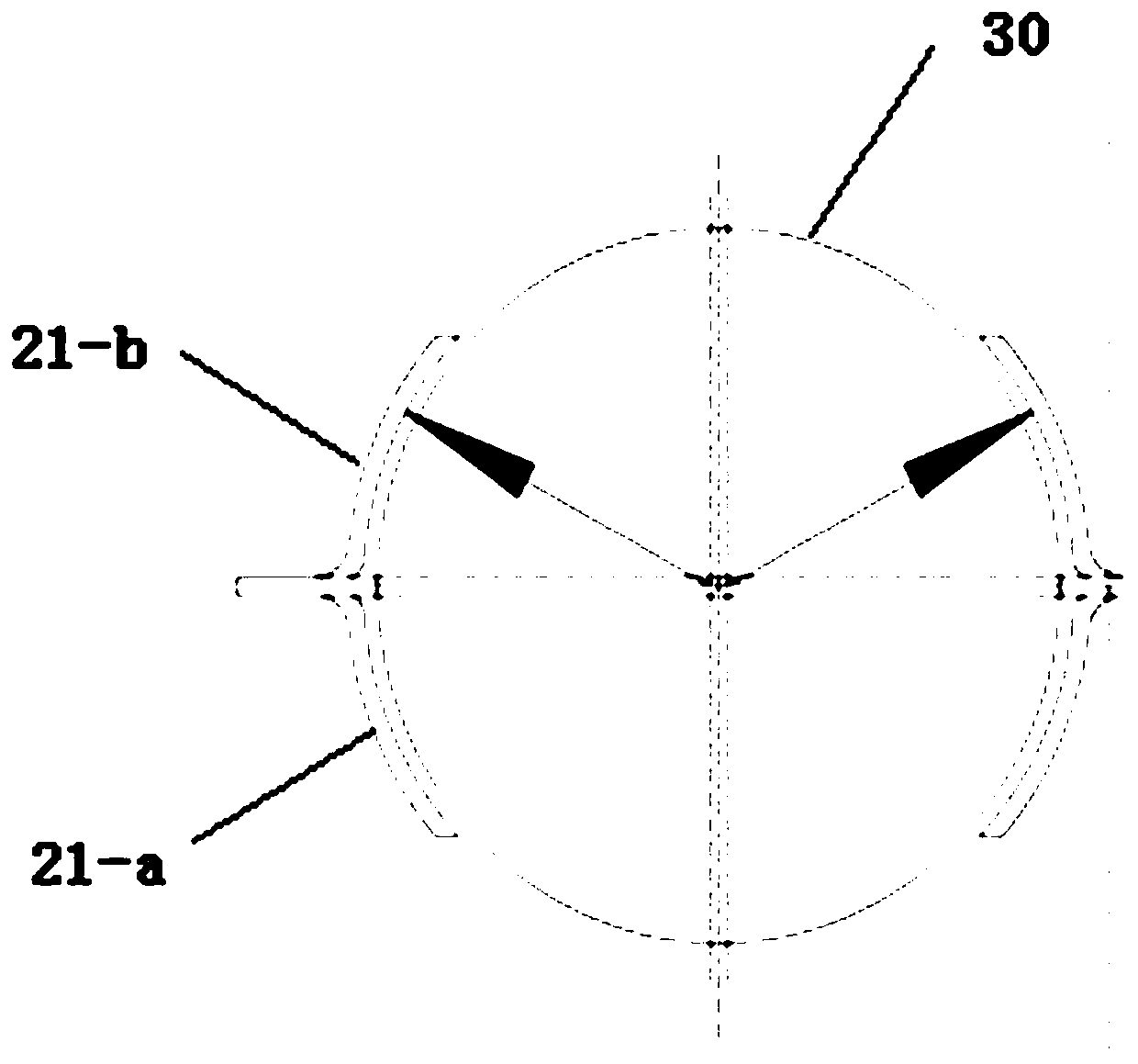

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0019] The cage is one of the main parts of the linear guide. The main function of the cage in the linear guide is to separate the rolling elements; hold the rolling elements themselves; guide the rolling elements to roll on the correct track; orient the rolling elements and reduce friction . Therefore, the cage material is required to have high wear resistance, but high hardness needs to prevent "cohesion"; high fatigue strength; necessary elasticity and toughness; small friction loss, which can ease the impact of rolling elements entering and leaving the load zone; pressure processing Relatively good performance; sufficient rigidity and flexibility; small friction coefficient, chemically stable, subject to external magnetic field, not easy to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com