Anti-rollover metal vibration damping support

An anti-rollover and metal technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problem that the beam body rollover of the viaduct is not prevented, the support cannot be practically applied to the viaduct, and the lateral movement and up and down movement of the beam body cannot be locked. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

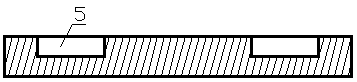

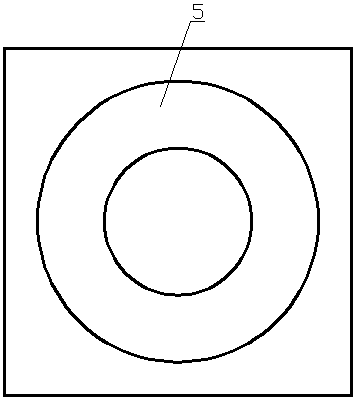

[0086] The anti-rollover metal damping support includes a guide slide body 1 composed of a transverse limiting part, a locking limiting part 8 and a bearing part, and a longitudinal sliding lower plate 3, an annular oblique spring 11 and a longitudinal sliding upper block 2 or a longitudinal sliding group composed of longitudinal sliding lower plate 3, disc spring 11 and longitudinal sliding upper block 2, and guide slide groove 7 on guide slide seat body 1; there are the following twelve technical solutions:

[0087] 1. A longitudinal sliding group consisting of the lower longitudinal guiding block 3, the annular oblique spring 11 and the upper longitudinal sliding block 2, the lower longitudinal guiding sliding block 3 and the upper longitudinal sliding block 2 adopt annular grooves; the technical scheme is as follows:

[0088]Have a long opening on the long side so that the cross section of the rectangular tubular guide slide body 1 is a convex guide chute 7, and the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com