Treatment process of ship tail gas denitration waste catalyst

A technology for denitrification waste catalysts and ship exhaust, which is applied in the field of resource regeneration and recycling, can solve the problems of high energy consumption in roasting, low enrichment efficiency of valuable elements, and large amount of waste water, so as to shorten the leaching time and reduce evaporation and crystallization The effect of small time and three wastes produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

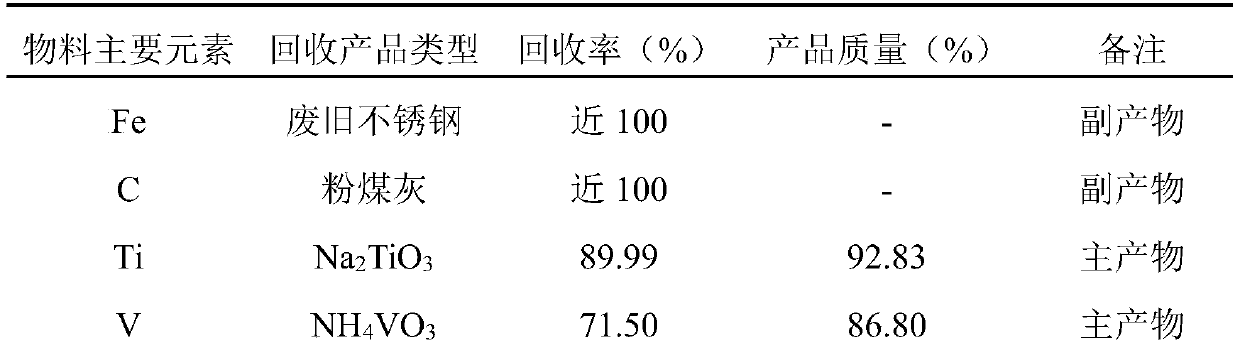

Embodiment 1

[0039] A process for treating waste catalyst for denitrification of ship tail gas, comprising the following steps:

[0040] S1. Pretreatment of waste catalyst for denitrification of ship tail gas: first, crush and disassemble the waste catalyst for denitrification of ship tail gas, and recycle waste stainless steel; then, crush and sieve it, and ventilate during the process to remove dust by vacuuming Fly ash is recovered; finally, it is further ground to obtain a material containing titanium, vanadium and tungsten with a particle size of ≤200 mesh.

[0041] S2. Titanium recovery: take 100g of the material obtained in step S1, add 1 times the theoretical amount (90g) of NaOH solution to the material, then add 100ml of water, and carry out alkaline immersion at 100°C and 0.5MPa for 60min. After filtering and washing the slag with hot water, the volume of the first leaching solution was 128mL and the mass of the first leaching residue was 145.90g.

[0042] ICP was used to analy...

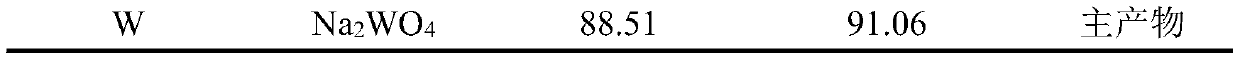

Embodiment 2

[0050] A process for treating waste catalyst for denitrification of ship tail gas, comprising the following steps:

[0051] S1. Pretreatment of waste catalyst for denitrification of ship tail gas: first, crush and disassemble the waste catalyst for denitrification of ship tail gas, and recycle waste stainless steel; then, crush and sieve it, and ventilate during the process to remove dust by vacuuming Fly ash is recovered; finally, it is further ground to obtain a material containing titanium, vanadium and tungsten with a particle size of ≤200 mesh.

[0052] S2, recovering titanium: take 100g of the material obtained in step S1, add 1.1 times the theoretical amount (100g) of NaOH solution to the material, then add 200ml of water, and carry out alkaline immersion at 150°C and 1.0MPa for 90min. After filtering and washing the slag with hot water, the volume of the first leaching solution is 224mL and the mass of the first leaching residue is 142.68g.

[0053] ICP was used to an...

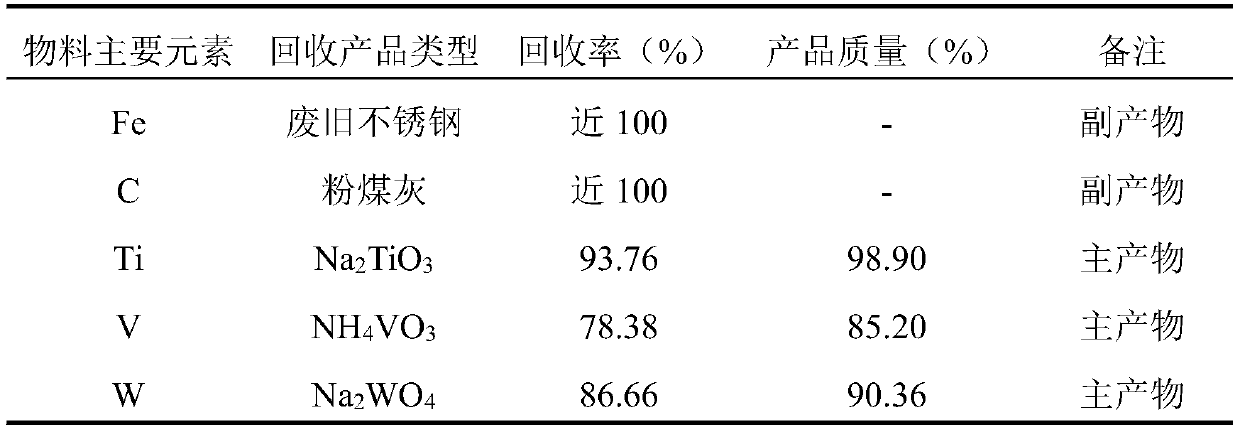

Embodiment 3

[0060] A process for treating waste catalyst for denitrification of ship tail gas, comprising the following steps:

[0061] S1. Pretreatment of waste catalyst for denitrification of ship tail gas: first, crush and disassemble the waste catalyst for denitrification of ship tail gas, and recycle waste stainless steel; then, crush and sieve it, and ventilate during the process to remove dust by vacuuming Fly ash is recovered; finally, it is further ground to obtain a material containing titanium, vanadium and tungsten with a particle size of ≤200 mesh.

[0062] S2, recovery of titanium: take 100g of the material obtained in step S1, add 1.2 times the theoretical amount (108g) of NaOH solution to the material, then add 400ml of water, and carry out alkaline immersion at 200°C and 1.5MPa for 120min. After filtering and washing the slag with hot water, the volume of the first leaching solution was 483 mL and the mass of the first leaching residue was 150.48 g.

[0063] ICP was used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com