Method for harmless treatment of oil sludge sand

A technology for harmless treatment of oily sludge, applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of high input-output ratio, lower processing cost, and simple and convenient equipment installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

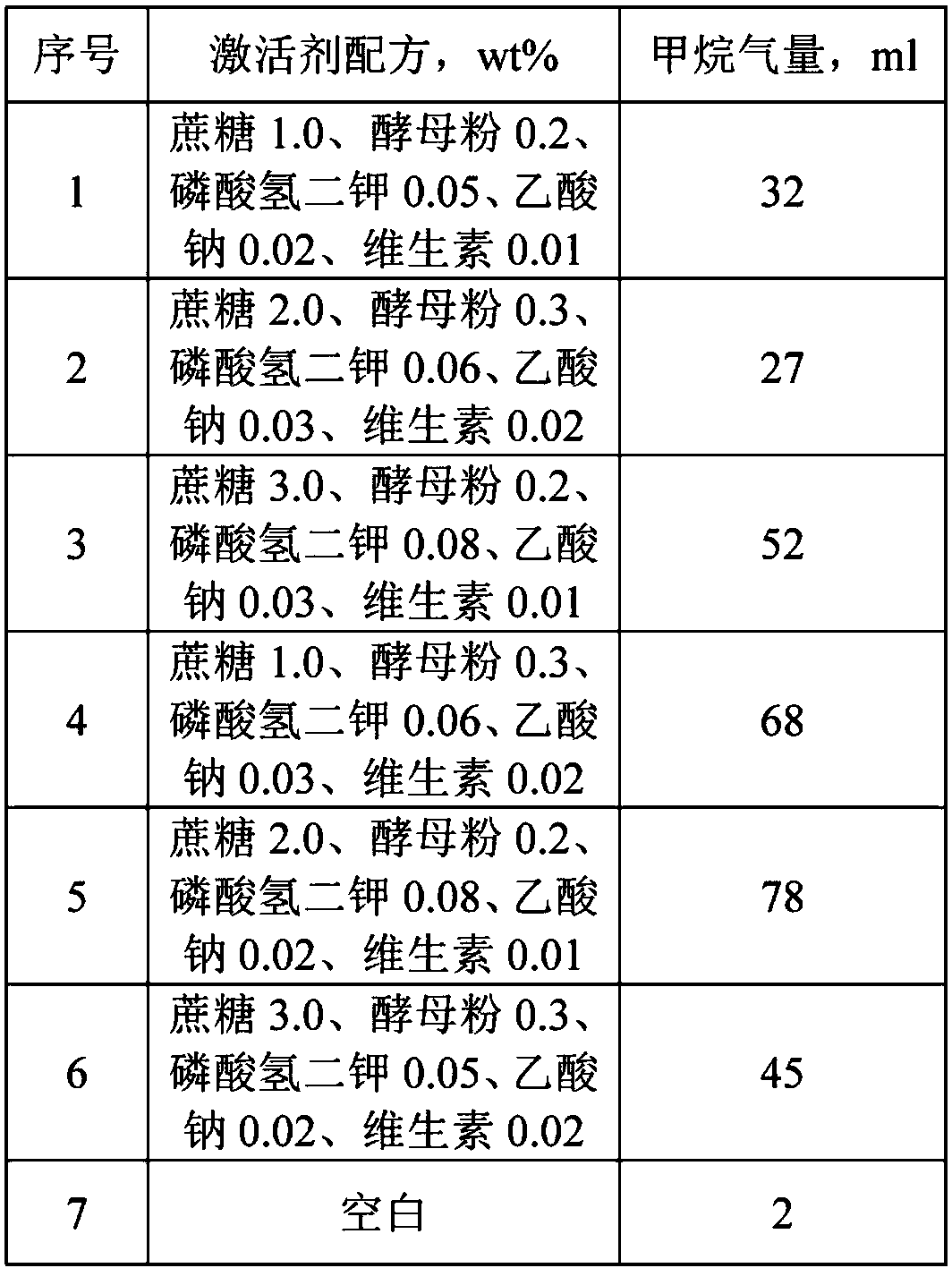

Examples

Embodiment 1

[0026] A joint station G in Shengli Oilfield 21 The properties of the oil sludge sand are as follows: oil content 15.3%, water content 20.5%, average particle size 80 μm, the bacterial concentration of Serratia in the oil sludge sand 2.0×10 2 individual / ml, the bacterial concentration of Methanococcus 1.0×10 3 / ml, the bacterial concentration of anaerobic desulfurization bacteria 1.0×10 3 pieces / ml.

[0027] An abandoned oil reservoir L in Shengli Oilfield 35 , reservoir temperature 75℃, permeability 1200×10 -3 μm 2 , formation water salinity 78525mg / L, crude oil viscosity 1256mPa·s, residual oil saturation 25.6%, recovery degree 35.3%.

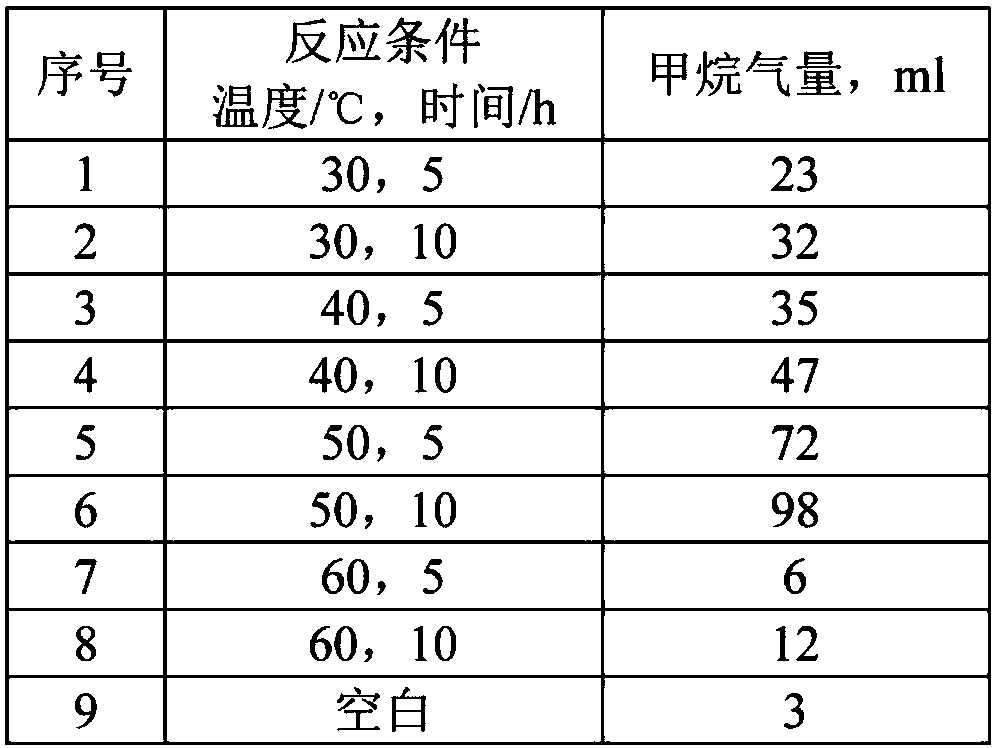

[0028] Utilize the method of the present invention to unite station G 21 The oil sludge sand is harmlessly treated and applied to the abandoned oil reservoir L 35 It is used to increase the oil production and methane gas production of abandoned oil reservoirs. The specific steps are as follows:

[0029] (1) Screening of oil sludge san...

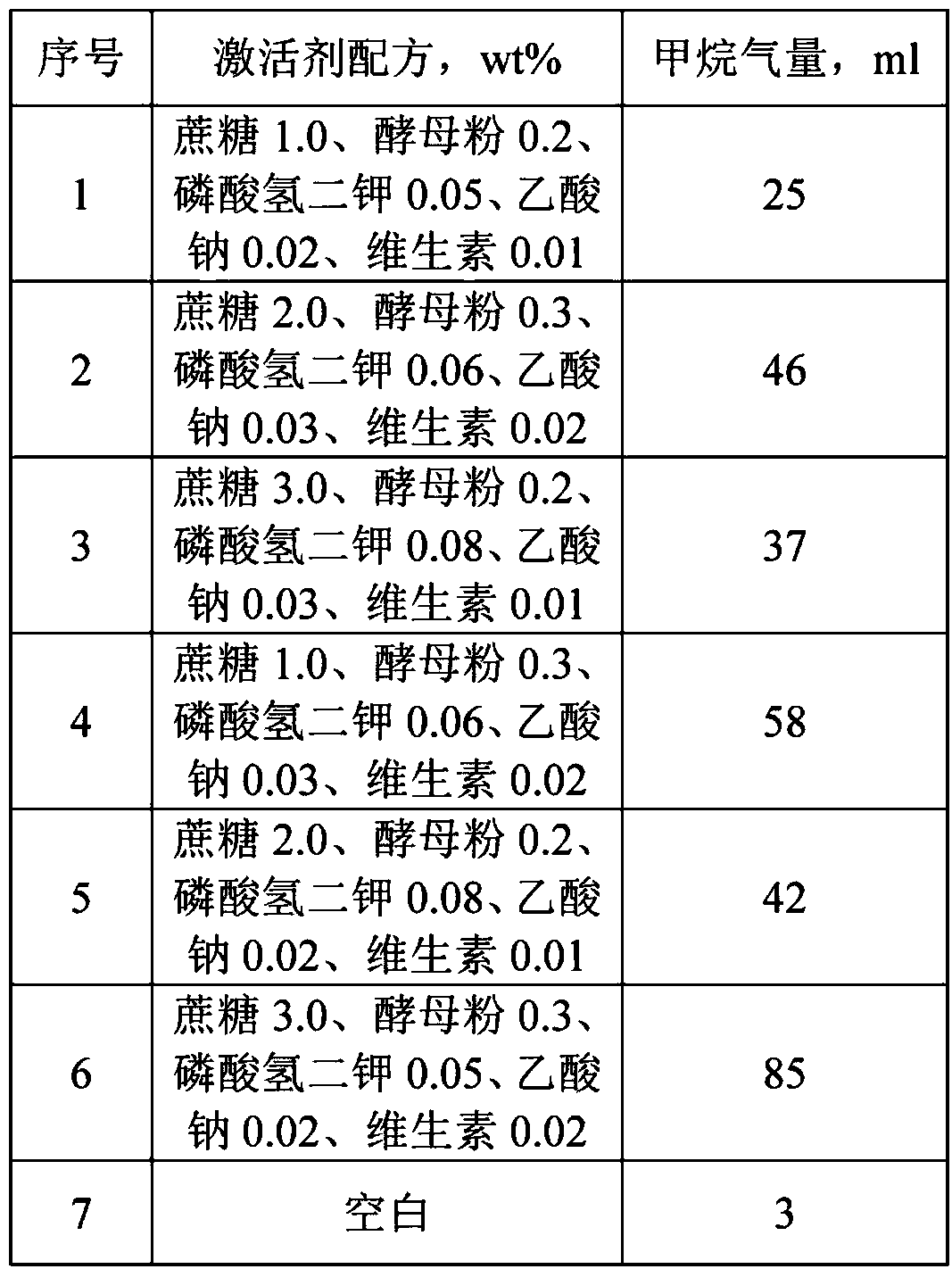

Embodiment 2

[0049] A joint station G in Shengli Oilfield 45 The properties of oil sludge sand are as follows: oil content is 17.2%, water content is 22.3%, average particle size is 50 μm, and the bacterial concentration of Arthrobacter in oil sludge sand is 1.0×10 3 individual / ml, the bacterial concentration of Methanosarcina 2.0×10 3 unit / ml, the bacterial concentration of Acinetobacter 2.0×10 2 pieces / ml.

[0050] AR of an abandoned oil reservoir in Shengli Oilfield 5 , reservoir temperature 70℃, permeability 1500×10 -3 μm 2 , Formation water salinity 12568mg / L, crude oil viscosity 2562mPa·s, residual oil saturation 27.2%, recovery degree 32.5%.

[0051] Utilize the method of the present invention to unite station G 45 Harmless treatment of oil sludge sand and application in abandoned oil reservoir AR 5 It is used to increase the oil production and methane gas production of abandoned oil reservoirs. The specific steps are as follows:

[0052] (1) Screening of oil sludge sand

...

Embodiment 3

[0073] D of a joint station in Shengli Oilfield 5 The properties of oil sludge sand are as follows: oil content 19.2%, water content 22.3%, average particle size 60 μm, bacterial concentration of Sphingomonas in oil sludge sand 2.0×10 2 individual / ml, the bacterial concentration of Methanobacterium thermobacterium 2.0×10 3 pcs / ml, concentration of anaerobic Desulfobacillus bacteria 2.0×10 3 pieces / ml.

[0074] An abandoned oil reservoir in Shengli Oilfield M 25 , reservoir temperature 82℃, permeability 500×10 -3 μm 2 , formation water salinity 32567mg / L, crude oil viscosity 985mPa·s, residual oil saturation 21.3%, recovery degree 31.5%.

[0075] Utilize the method of the present invention to union station D 5 The oil sludge sand is treated harmlessly and applied to the abandoned oil reservoir M 25 It is used to increase the oil production and methane gas production of abandoned oil reservoirs. The specific steps are as follows:

[0076] (1) Screening of oil sludge sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com