FeS nanoparticle synthesized based on solvothermal method, and preparation method and application thereof

A nanoparticle, solvothermal technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the cumbersome preparation process of pyrrhotite FeS, the dependence on surfactants and solvents, The reaction has not been reported and other problems, to achieve the effect of good removal, good conductivity and adjustable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

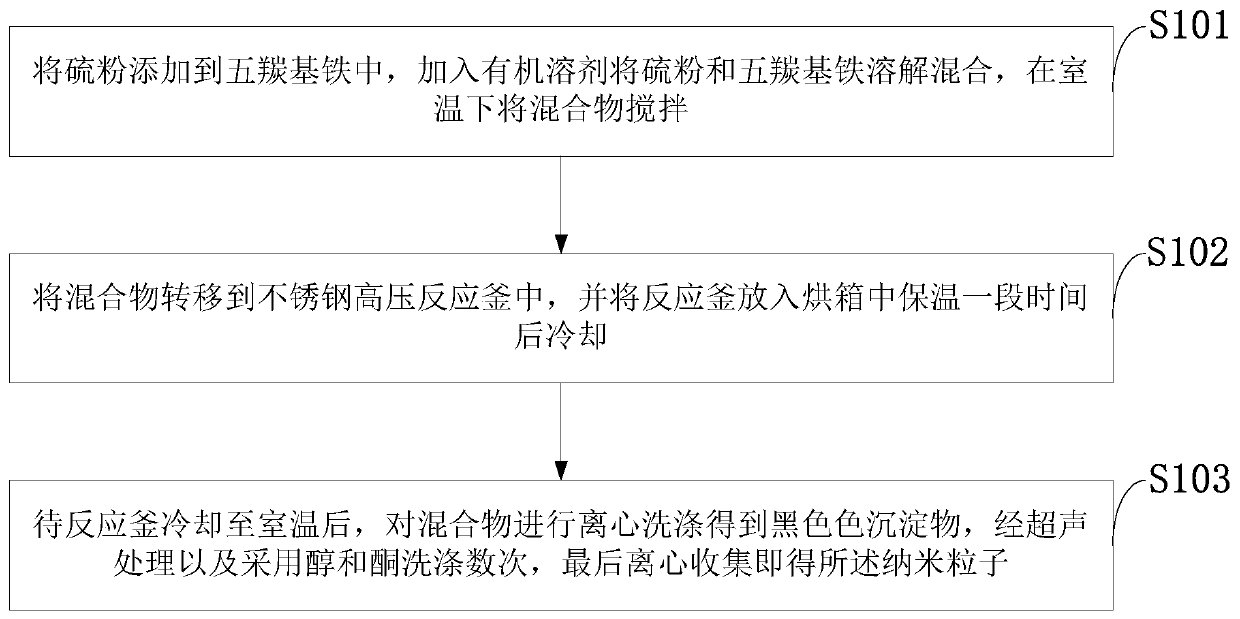

[0033] Such as figure 1 As shown, the preparation method of FeS nanoparticles synthesized based on solvothermal method provided by the embodiments of the present invention comprises the following steps:

[0034] S101: adding sulfur powder to iron pentacarbonyl, adding an organic solvent to dissolve and mix the sulfur powder and iron pentacarbonyl, and stirring the mixture at room temperature;

[0035] S102: transfer the mixture to a stainless steel autoclave, and put the autoclave into an oven to keep it warm for a period of time and then cool it down;

[0036] S103: After the reactor is cooled to room temperature, the mixture is centrifuged and washed to obtain a black precipitate, which is ultrasonically treated and washed several times with alcohol and ketone, and finally collected by centrifugation to obtain the nanoparticles.

[0037] The preparation method of FeS nanoparticles synthesized based on solvothermal method provided in the embodiment of the present invention s...

Embodiment 1

[0046] The preparation method of FeS nanoparticles synthesized based on solvothermal method provided in the embodiment of the present invention specifically includes the following steps:

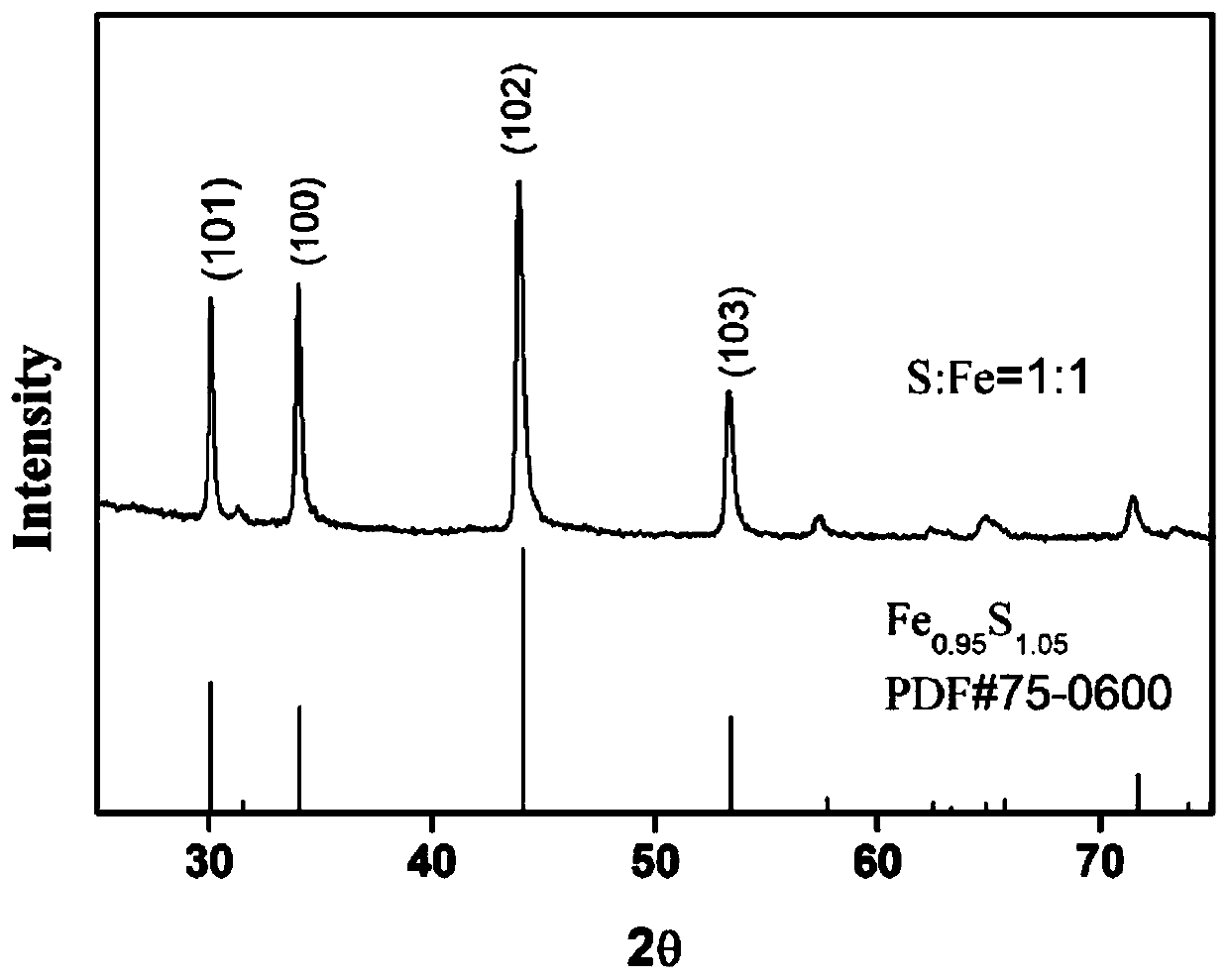

[0047] First, 1.5ml of iron pentacarbonyl was added dropwise to 1g of sulfur powder, then 35ml of p-xylene was added, the mixture was magnetically stirred at room temperature at 1200 rpm for 15 minutes, and then transferred to a stainless steel autoclave , and then the autoclave was placed in an oven at 210°C for 24 hours. After the autoclave was cooled to room temperature, it was centrifuged and washed to obtain a black precipitate, which was then ultrasonically treated and washed several times with isopropanol and acetone, and finally centrifuged at a speed of 12,000 rpm for 10 minutes to collect the product to obtain the product FeS. Such as figure 1 Shown is the SEM picture of the flower-cluster-shaped FeS nanoparticles prepared in Example 1 of the present invention; figure 2 X-ray di...

Embodiment 2

[0049] The preparation method of FeS nanoparticles synthesized based on solvothermal method provided in the embodiment of the present invention specifically includes the following steps:

[0050] First, 1.5ml of iron pentacarbonyl was added dropwise to 1.5g of sulfur powder, then 35ml of p-xylene was added, the mixture was magnetically stirred at room temperature at 1200 rpm for 15 minutes, and then transferred to a stainless steel high pressure reaction The autoclave was then placed in an oven at 210°C for 24 hours. After the autoclave was cooled to room temperature, it was centrifuged and washed to obtain a black precipitate, which was then ultrasonically treated and washed several times with isopropanol and acetone, and finally centrifuged at a speed of 12,000 rpm for 10 minutes to collect the product to obtain the product FeS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com