Light warm-keeping fabric

A fabric and lightweight technology, applied in the field of knitted fabrics, can solve the problem of limited cold-proof effect, and achieve the effect of improving cold-proof performance, excellent thermal insulation performance, and lightweight raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

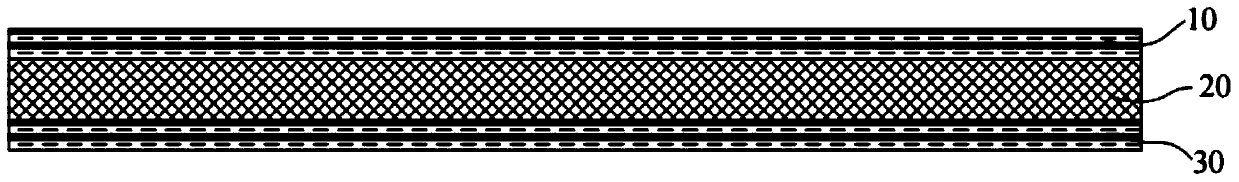

[0020] Example 1: see figure 1 As shown, a light-weight thermal insulation fabric includes an outer dense thermal insulation layer 10 sewn into one and located on the surface, a hollow thermal insulation layer 20 located in the middle, and an inner dense thermal insulation layer 30 located on the inner layer, wherein the outer dense thermal insulation layer The raw material of layer 10 is the superfine fiber-wool blended yarn prepared by 80% superfine fiber with a public count of 1500N and 20% wool fiber through the blending process, and the superfine fiber-wool blended yarn is used as Warp yarns and weft yarns are manufactured to obtain an outer dense thermal insulation layer 10, which ensures the thermal resistance of the fabric and is used to improve the cold resistance of the surface of the fabric. Yarns are manufactured as warp yarns and weft yarns to obtain a hollow insulation layer 20. Since the hollow fiber has a thin tubular cavity in the axial direction, the hollowne...

Embodiment 2

[0021] Embodiment 2: the technical scheme of this embodiment 2 is the same as that of embodiment 1, the difference is that: this embodiment 2 proposes a kind of light-weight thermal insulation fabric, and the outer surface of the outer dense thermal insulation layer is sewn waterproof fabric, and this embodiment 1 makes The lightweight thermal fabric has a grammage of 245 grams per square meter.

Embodiment 3

[0022] Embodiment 3: The technical solution of this embodiment 3 is the same as that of embodiment 1, the difference is that: this embodiment 3 proposes a light-weight warm-keeping fabric, and the hollow fiber yarn adopts 90% hollow fiber and 10% phase change fiber blending When the external temperature rises, the phase change fiber absorbs heat energy and melts to store heat in the hollow insulation layer, and when the external temperature decreases, it releases heat and crystallizes to release heat to the hollow insulation layer; specifically, in this In an embodiment, the phase-change fiber adopts Comfort Temp constant-temperature phase-change fiber sold by Swiss Scholler Company.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com