A kind of preparation method of highly conductive polyester film

A polyester film, high conductivity technology, applied in conductive coatings, coatings and other directions, can solve the problems of short duration of conductive performance of conductive films, poor conductivity of conductive polyester films, easy to agglomerate and other problems, saving preparation Steps, lowering temperature, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

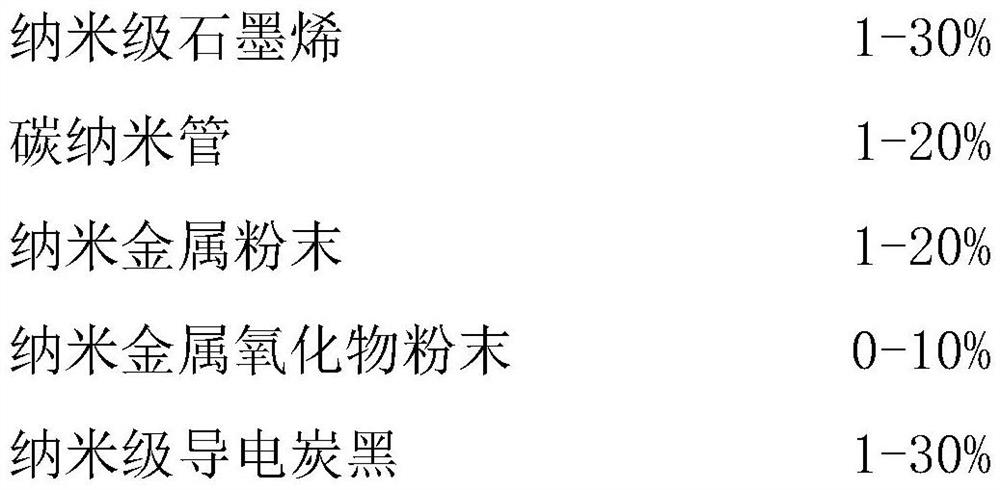

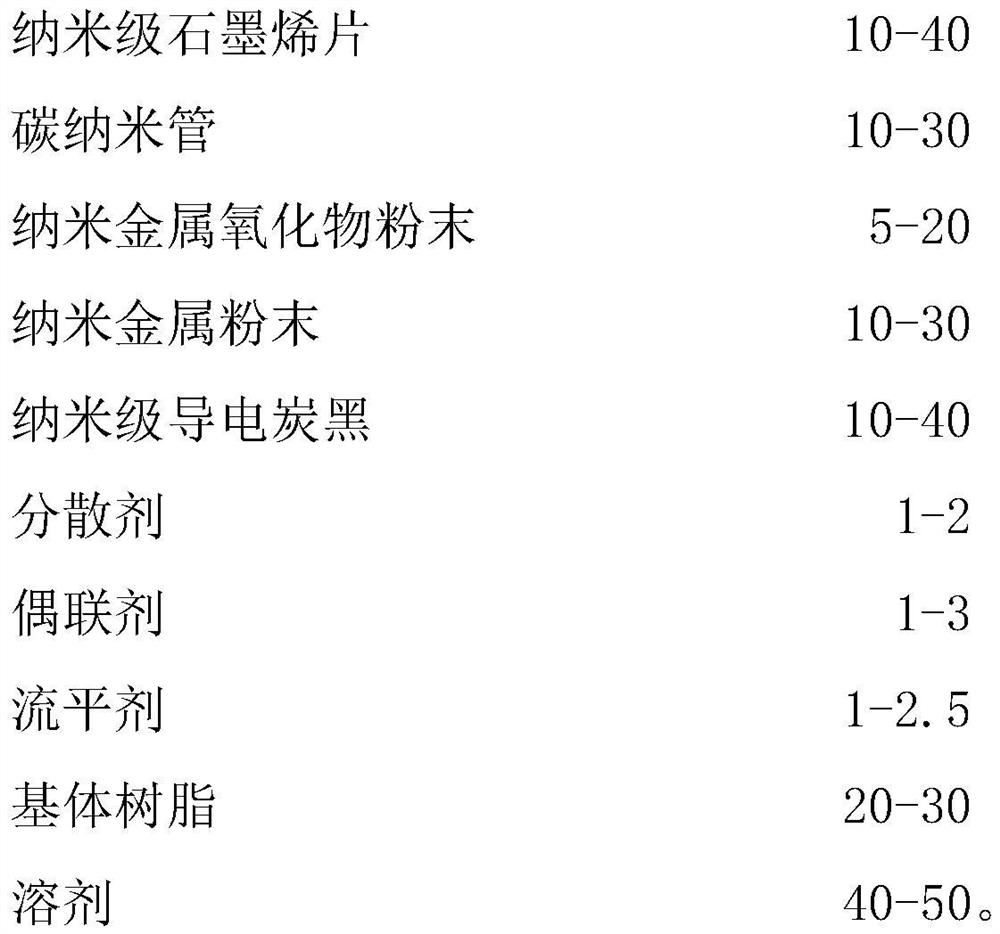

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of high conductivity polyester film, it comprises following preparation steps:

[0043] Step 1. Pre-crystallize and dry the conductive polyester masterbatch. The drying temperature is 170°C. Then put the conductive polyester masterbatch into a single-screw extruder for heating, melting and plasticization. The extrusion temperature is 280°C to obtain a polyester thick film;

[0044] Step 2. Stretch the polyester thick film by biaxial stretching method, the longitudinal stretching temperature is 85°C, the transverse stretching temperature is 105°C, the thickness of the stretched polyester film is 0.3mm, and then the temperature is raised The polyester film after stretching is set, and the setting temperature is 235°C;

[0045] Step 3: Spray conductive paint on the surface of the shaped polyester film by spraying process, the temperature of the sprayed polyester film is 100°C, and the spraying thickness is 0.1mm;

[0046] Step 4: Carrying out...

Embodiment 2

[0063] A kind of preparation method of high conductivity polyester film, it comprises following preparation steps:

[0064] Step 1. Pre-crystallize and dry the conductive polyester masterbatch, the drying temperature is 150-190°C, and then put the conductive polyester masterbatch into a single-screw extruder for heating, melting and plasticization. The single-screw extruder The extrusion temperature in the process is 270°C-290°C to obtain thick polyester film;

[0065] Step 2: Stretch the polyester thick film by bidirectional stretching method, the longitudinal stretching temperature is 80-90°C, the transverse stretching temperature is 100-110°C, and the thickness of the stretched polyester film is 0.3 mm, then heat up to shape the stretched polyester film, and the setting temperature is 230-240°C;

[0066] Step 3: Spray conductive paint on the surface of the shaped polyester film by spraying process, the temperature of the sprayed polyester film is 50-150°C, and the spraying...

Embodiment 3

[0083] A kind of preparation method of high conductivity polyester film, it comprises following preparation steps:

[0084] Step 1. Pre-crystallize and dry the conductive polyester masterbatch, the drying temperature is 150-190°C, and then put the conductive polyester masterbatch into a single-screw extruder for heating, melting and plasticization. The single-screw extruder The extrusion temperature in the process is 270°C-290°C to obtain thick polyester film;

[0085] Step 2: Stretch the polyester thick film by bidirectional stretching method, the longitudinal stretching temperature is 80-90°C, the transverse stretching temperature is 100-110°C, and the thickness of the stretched polyester film is 0.3 mm, then heat up to shape the stretched polyester film, and the setting temperature is 230-240°C;

[0086] Step 3: Spray conductive paint on the surface of the shaped polyester film by spraying process, the temperature of the sprayed polyester film is 50-150°C, and the spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com